Device and method for modifying rabbit hair fiber product

A rabbit hair fiber and processing device technology, which is applied in the field of rabbit hair processing, can solve the problems of fabric style influence and poor effect, and achieve the effect of reducing hair loss, soft hand feeling and preventing size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

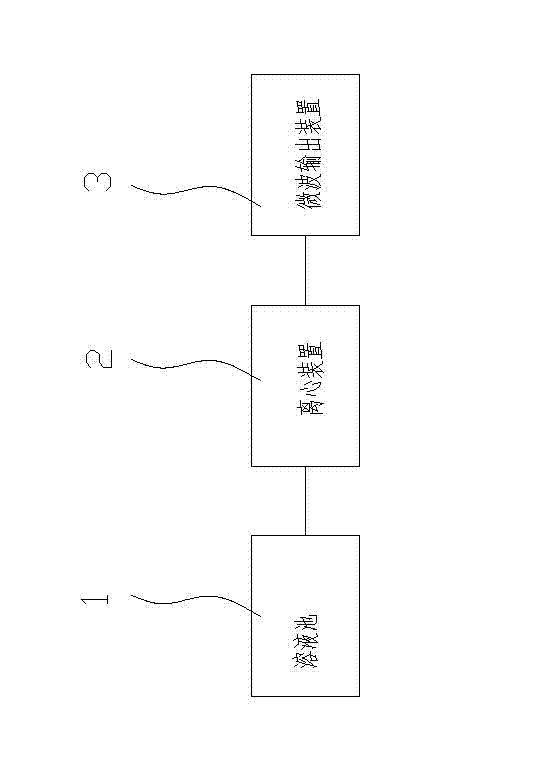

Image

Examples

Embodiment 1

[0011] Example 1, immerse 1Kg of rabbit hair fiber products in a chemical modification treatment agent solution, the bath ratio is 1:6, add 0.005Kg of ammonium mercaptoacetate, 0.002Kg of 1-dodecylazepane-2 to the aqueous solution - For ketones, the impregnation temperature is 20°C and the impregnation time is 30 minutes. After completion, it was dehydrated by centrifugation. Then, it was processed for 4 minutes under the action of microwave with a frequency of 2450 MHz and a microwave output power of 600 W. Next, add the impregnation pre-polymerization solution, the bath ratio is 1:6, add 0.5Kg N,N'-methylenebisacrylamide, 0.005Kg ammonium persulfate, 0.03Kg hydrogen peroxide into the aqueous solution, and the immersion temperature is 20°C. The time is 30 minutes. After completion, it was dehydrated by centrifugation. Then, it was processed for 5 minutes under the action of microwave with a frequency of 2450 MHz and a microwave output power of 1500 W.

Embodiment 2

[0012] Example 2, immerse 1Kg of rabbit hair fiber products in the chemical modification treatment agent solution, the bath ratio is 1:15, add 0.05Kg of ammonium mercaptoacetate, 0.01Kg of 1-dodecylazepane-2 to the aqueous solution - For ketones, the immersion temperature is 45°C and the immersion time is 10 minutes. After completion, it was dehydrated by centrifugation. Then, it was treated for 10 minutes under the action of microwave with a frequency of 2450 MHz and a microwave output power of 600 W. Next, add the impregnation pre-polymerization solution, the bath ratio is 1:15, add 3 Kg N,N'-methylenebisacrylamide, 0.025Kg ammonium persulfate into the aqueous solution, the immersion temperature is 45 ° C, and the immersion time is 10 minutes . After completion, it was dehydrated by centrifugation. Then, it was processed for 15 minutes under the action of a microwave with a frequency of 2450 MHz and a microwave output power of 500 W.

Embodiment 3

[0013] Example 3, 1Kg of rabbit hair fiber products is immersed in the chemical modification treatment agent solution, the bath ratio is 1:10, 0.025Kg of mercapto ammonium acetate and 0.006Kg of 1-dodecylazepane-2 are added to the aqueous solution - For ketones, the impregnation temperature is 30°C and the impregnation time is 20 minutes. After completion, it was dehydrated by centrifugation. Then, it was processed for 8 minutes under the action of microwave with a frequency of 2450 MHz and a microwave output power of 600 W. Next, add the impregnation pre-polymerization solution, the bath ratio is 1:10, add 1.5 Kg N,N'-methylenebisacrylamide, 0.01Kg ammonium persulfate into the aqueous solution, the immersion temperature is 30°C, and the immersion time is 20 minutes . After completion, it was dehydrated by centrifugation. Then, it was processed for 10 minutes under the action of microwave with a frequency of 2450 MHz and a microwave output power of 1000 W.

[0014] The inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com