Dyeing and finishing processing method of napping fabric

A processing method and fabric technology, applied in the field of home textiles, can solve the problems of strong cotton fiber damage, secondary hairiness, etc., and achieve the effect of less hair loss and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

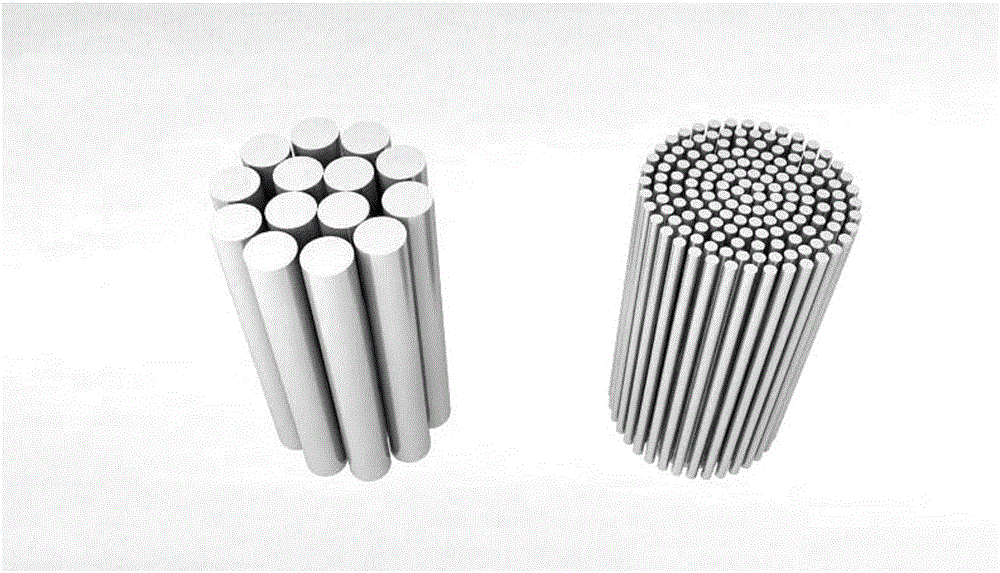

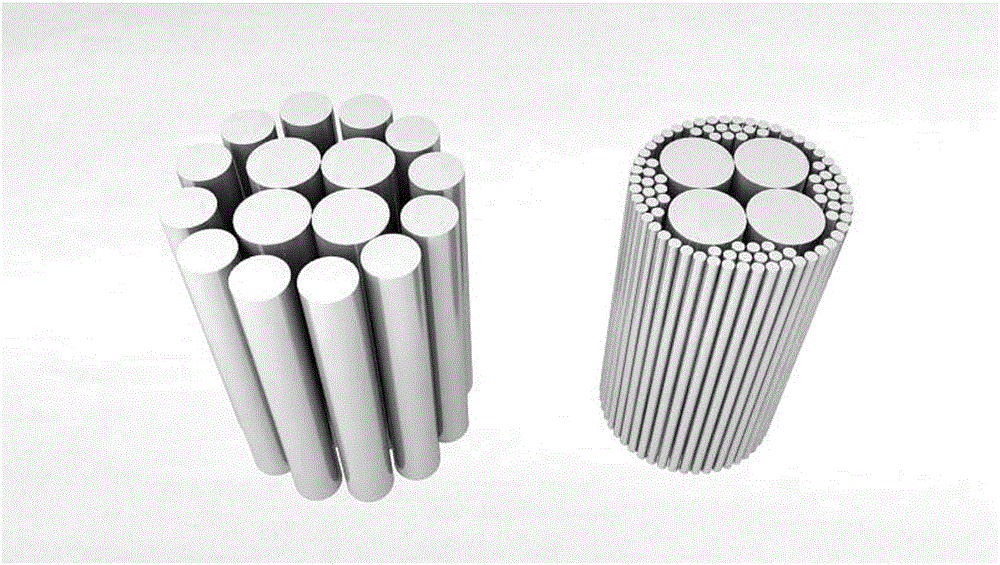

Method used

Image

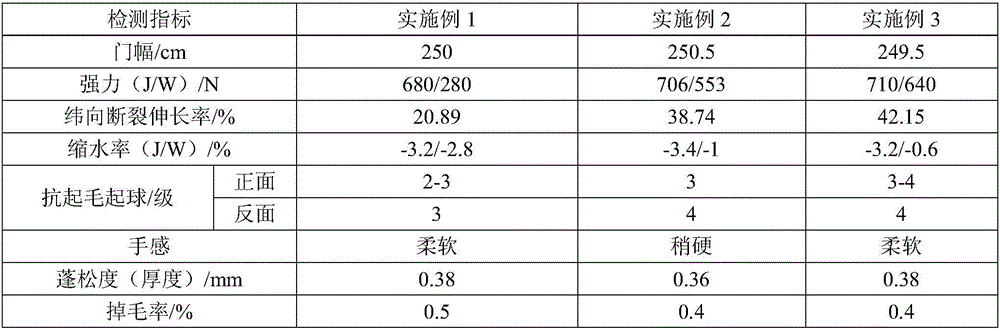

Examples

Embodiment 1

[0030] Fabric: 105" / C32S*sea island silk 160D / 133*80 twill

[0031] Technological process: Cloth turning seam → singeing → enzyme desizing → scouring → bleaching → tenter whitening → sanding → printing → steaming → washing → softness and shaping → preshrinking → finished product rolling

[0032] Singeing: two fronts and one back singeing, the machine speed is 100-110°C, the flame temperature on the warp face is 1300-1400°C, and the flame temperature on the weft face is 900°C.

[0033] Enzyme desizing: After singeing, pad the amylase working solution to extinguish the fire, and pile it up for 4-6 hours.

[0034]Scouring: There are 6-8 high-temperature washing tanks in the front and back of the steaming box, the steaming time is 60 minutes, the steaming temperature is 102°C, the concentration of caustic soda in the working solution is 50g / L, and the scouring agent is 4-8g / L. The concentration of TF101 is 6g / L, and the concentration of chelating dispersant is 8g / L.

[0035] Ble...

Embodiment 2

[0042] 106.5” / C32S* sea-island yarn composite yarn 160D / 133*80 twill, sea-island yarn: POY=4:1

[0043] Technological process: Cloth turning seam → singeing → enzyme desizing → scouring → bleaching → tenter whitening → sanding → printing → steaming → washing → softness and shaping → preshrinking → finished product rolling

[0044] Singeing: two fronts and one back singeing, speed 100-110°C. Among them, the flame temperature on the warp surface is 1200-1300°C, and the flame temperature on the weft surface is 800°C.

[0045] Enzyme desizing: After singeing, pad the amylase working solution to extinguish the fire, and pile it up for 4-6 hours.

[0046] Scouring: There are 6-8 grids of high-temperature washing tanks at the front and back of the steaming box, the steaming time is 60 minutes, the steaming temperature is 102°C, the concentration of caustic soda in the working liquid is 45g / L, and the scouring agent is 4-8g / L during scouring. The concentration of TF101 is 6g / L, and ...

Embodiment 3

[0054] 106.5” / C32S* sea-island yarn composite yarn 225D / 133*69 twill, sea-island yarn: POY=7:1

[0055] Technological process: Cloth turning seam → singeing → enzyme desizing → scouring → bleaching → tenter whitening → sanding → printing → steaming → washing → softness and shaping → preshrinking → finished product rolling

[0056] Singeing: two fronts and one back singeing, speed 100-110°C. Among them, the flame temperature on the warp surface is 1200-1300°C, and the flame temperature on the weft surface is 900°C.

[0057] Enzyme desizing: After singeing, pad the amylase working solution to extinguish the fire, and pile it up for 4-6 hours.

[0058] Scouring: There are 6-8 grids of high-temperature washing tanks at the front and back of the steaming box, the steaming time is 60 minutes, the steaming temperature is 102°C, the concentration of caustic soda in the working liquid is 55g / L, and the scouring agent is 4-8g / L during scouring. The concentration of TF101 is 6g / L, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com