Environment-friendly three-dimensional wear-resistant packaging paper and production process thereof

A production process and packaging paper technology, which are applied in the field of environmentally friendly three-dimensional wear-resistant packaging paper and its production process, can solve the problems of uneven cutting position of packaging paper, unable to ensure that the packaging paper does not wrinkle, and unsatisfactory water resistance effect, etc. The effect of reducing hair loss, improving aesthetics and texture, improving surface strength and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

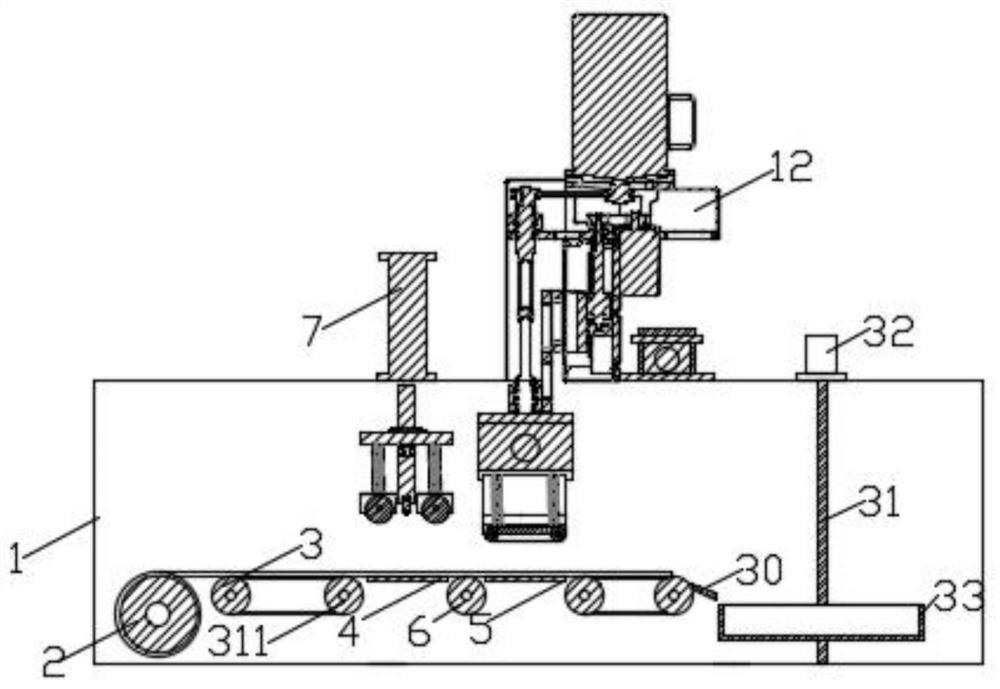

Image

Examples

Embodiment 1

[0032] An environmentally friendly three-dimensional wear-resistant wrapping paper, prepared from the following raw materials in parts by weight: 100 parts of biodegradable bamboo fiber, 20 parts of starch, 5 parts of rosin glue, 10 parts of talcum powder, 5 parts of titanium dioxide, and 3 parts of wet strength agent 1 part, 3 parts of dry strength agent, 3 parts of retention aid, 1 part of turpentine and 1 part of paraffin;

[0033] Wherein, the environment-friendly three-dimensional wear-resistant wrapping paper is prepared through the following steps:

[0034] Step 1: Take biodegradable bamboo fiber, starch, rosin glue, talcum powder and titanium dioxide and put them into a mixing mixer for 20 minutes, and pass the stirred mixture through a filter to filter impurities to obtain a raw material mixture;

[0035] Step 2: Put the raw material mixture into the sedimentation container for precipitation, and add wet strength agent, dry strength agent, retention aid, turpentine an...

Embodiment 2

[0041] An environmentally friendly three-dimensional wear-resistant wrapping paper, prepared from the following raw materials in parts by weight: 150 parts of biodegradable bamboo fiber, 30 parts of starch, 10 parts of rosin glue, 20 parts of talcum powder, 10 parts of titanium dioxide, and 5 parts of wet strength agent 5 parts, 5 parts of dry strength agent, 5 parts of retention aid, 3 parts of turpentine and 3 parts of paraffin;

[0042] Wherein, the environment-friendly three-dimensional wear-resistant wrapping paper is prepared through the following steps:

[0043] Step 1: Take biodegradable bamboo fiber, starch, rosin glue, talcum powder and titanium dioxide and put them into a mixing mixer for 30 minutes, and pass the stirred mixture through a filter to filter impurities to obtain a raw material mixture;

[0044] Step 2: Put the raw material mixture into the sedimentation container for precipitation, and add wet strength agent, dry strength agent, retention aid, turpenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com