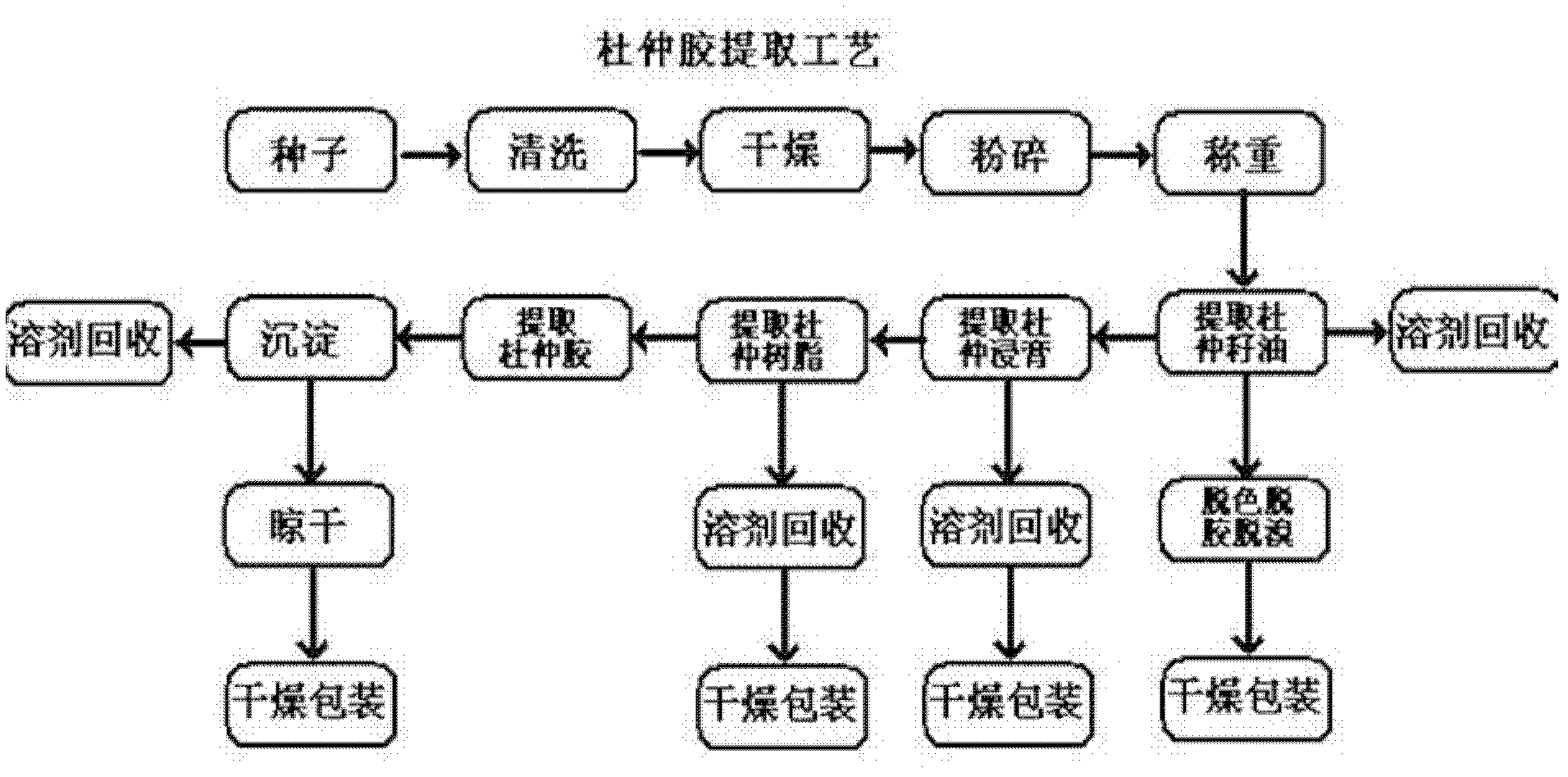

Method for circularly and continuously extracting eucommia gum, eucommia seed oil, eucommia extractum and eucommia resin from eucommia seeds

A cyclic continuous extraction and Eucommia seed oil technology, applied in the refining of natural resin, edible oil/fat, fat oil/fat production, etc., can solve the problems of high cost, high energy consumption and material consumption, single product, etc., to improve the efficiency of resource utilization , There is no three waste discharge, the effect of reducing energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] See figure 1 .

[0026] 1) After cleaning the eucommia seeds, dehydrate and dry them at a temperature of about 60-80°C (moisture content<10%), weigh 100g of the dried eucommia seeds, grind them to 50-80 mesh, and then use n-hexane (petroleum ether ) and Eucommia seeds in a weight ratio of 10:1, put the dried Eucommia seeds into the extraction reactor, use liquid nitrogen or dry ice to control the temperature at -10 to 0°C, add 1000ml of n-hexane (petroleum ether) , to extract, the extract is tan semi-finished Eucommia seed oil, the extract is subjected to decolorization, degumming, debromination and other oil conventional treatment processes to obtain 5.3g light yellow finished Eucommia seed oil; the extract is recovered through vacuum distillation ;

[0027] In order to improve the extraction rate, the extraction is to adopt 3 circulation extraction processes, and the time of each circulation extraction is 30 minutes;

[0028] 2) Dry the oil residue obtained after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com