Arcuation device for dense blind hole plate

A blind hole plate and arc rolling technology, applied in the field of mechanical processing, can solve the problems of inability to use the plate rolling machine, affecting the use effect, lax joints, etc., to achieve the effect of suitable promotion, easy operation and high quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

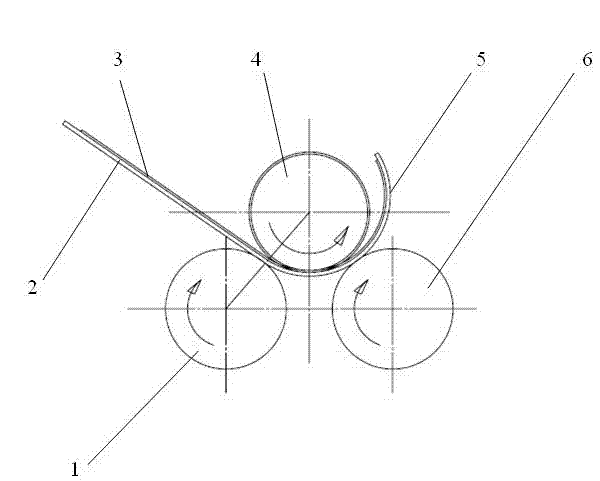

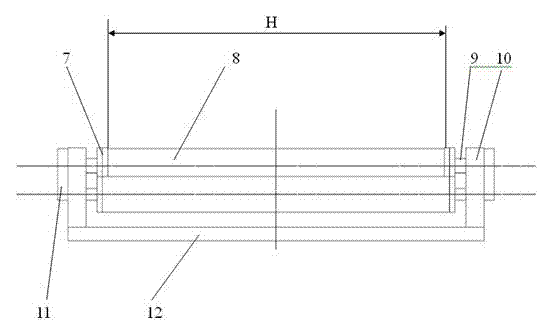

[0020] The invention provides an arc rolling device for a dense blind hole plate, such as figure 1 As shown, it is composed of three rollers, which are driving roller 1, driven pressing wheel 4 and guiding pressing wheel 6 respectively. Below the dynamic compression wheel 4, three rollers are arranged in the shape of "product"; the three rollers are respectively equipped with a blind hole plate limiter 7, and the extrusion surface of the driven compression wheel 4 is groove-shaped, and the two The end extrusion surface is higher than the extrusion surface of the middle section, and the height difference is the protruding height of the blind hole. Among the groove-shaped extrusion surfaces of the driven pinch wheel 4, the extrusion surface of the concave part is a rubber surface. like figure 2 As shown, the driving roller 1 , the driven pressing wheel 4 and the guiding pressing wheel 6 are respectively connected to the support wall 10 through the supporting shaft 9 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com