Production device and production method for coated duplex board with grey back

A production device and production method technology, applied in the direction of surface coating liquid device, coating, etc., can solve the problems of high energy consumption and investment in fixed equipment, increased environmental pressure, increased chemical consumption, etc., to achieve investment savings, chemical industry Effects of reduced consumption and reduced paper coating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the scope of the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the unspecified implementation conditions are usually the conditions in routine experiments.

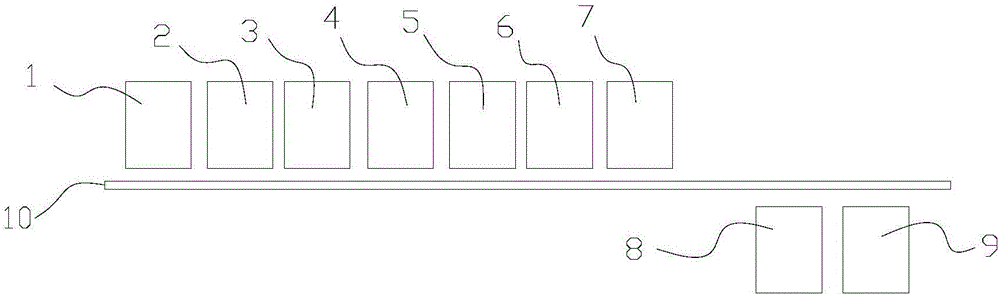

[0021] Such as figure 1 As shown, a production device for coated gray-bottomed white board paper includes a first coating device 1, a second coating device 5, and an atomizing water spraying device 8 arranged in sequence along the traveling direction of paper 7. The first The coating equipment 1 and the second coating equipment 5 are used for the first coating and the second coating on the surface layer of the paper 7 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com