Production method of high-rutin and high-niacin germinated tartary buckwheat tea

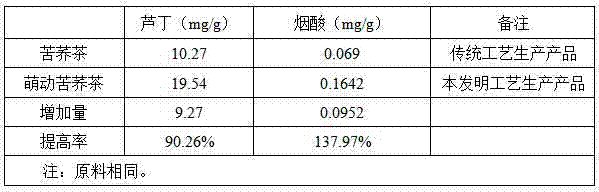

The technology of tartary buckwheat niacin and its production method is applied in the field of food processing, which can solve the problems of low content of bioflavonoids and rutin, poor taste, and large loss of effective substances, so as to improve technological content and added value, and ensure stability , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Select tartary buckwheat, and use existing methods to carry out two impurity removal processes and two stone removal processes to remove gravel, impurities and unfulfilled grains; the quality requirements of selected tartary buckwheat refer to relevant national standards, and the main quality indicators are: imperfect Grains ≤ 3.0%; sand content ≤ 0.02%; total impurities ≤ 1.5%; moisture ≤ 14.5%; normal color and smell; hygienic indicators are in accordance with the national standard GB2715-2005 "Food Sanitation Standard" and other relevant regulations. Put the tartary buckwheat after removing impurities into a cleaning tank, add water to wash it several times, and wash each time for 5 minutes, and the water level of the amount of water added for each cleaning is higher than the tartary buckwheat by 15cm, until the tartary buckwheat after removing impurities is cleaned, remove Dust and other impurities attached to the surface of the grain; in spring, according to the weig...

Embodiment 2

[0042] Select tartary buckwheat, and use existing methods to carry out two impurity removal processes and two stone removal processes to remove gravel, impurities and unfulfilled grains; the quality requirements of selected tartary buckwheat refer to relevant national standards, and the main quality indicators are: imperfect Grains ≤ 3.0%; sand content ≤ 0.02%; total impurities ≤ 1.5%; moisture ≤ 14.5%; normal color and smell; hygienic indicators are in accordance with the national standard GB2715-2005 "Food Sanitation Standard" and other relevant regulations. Put the tartary buckwheat after removing impurities in a cleaning tank, add water to wash it several times, and wash for 5 minutes each time, and the water level of the amount of water added for each cleaning is higher than the tartary buckwheat by 5cm, until the tartary buckwheat after removing impurities is cleaned, remove Dust and other impurities attached to the surface of the grain; in summer, according to the weight...

Embodiment 3

[0044] Select tartary buckwheat, and use existing methods to carry out two impurity removal processes and two stone removal processes to remove gravel, impurities and unfulfilled grains; the quality requirements of selected tartary buckwheat refer to relevant national standards, and the main quality indicators are: imperfect Grains ≤ 3.0%; sand content ≤ 0.02%; total impurities ≤ 1.5%; moisture ≤ 14.5%; normal color and smell; hygienic indicators are in accordance with the national standard GB2715-2005 "Food Sanitation Standard" and other relevant regulations. Put the tartary buckwheat after removing impurities in a cleaning tank, add water to wash it several times, and wash for 7 minutes each time. Dust and other impurities attached to the grain surface; in summer, according to the weight ratio of 1:2, take the washed tartary buckwheat and warm water with a temperature of 22 ℃ respectively, and soak the washed tartary buckwheat in warm water for 11 hours to make the bitter buc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com