Method for preparing oxidized graphene/conductive polypyrrole nano wire composite material

A pyrrole nano-composite material technology, used in cable/conductor manufacturing, circuits, capacitors, etc., can solve the problems of low specific capacitance of supercapacitor electrode materials, and improve the charge-discharge cycle stability and specific capacitance, high specific capacity and The effect of stability, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

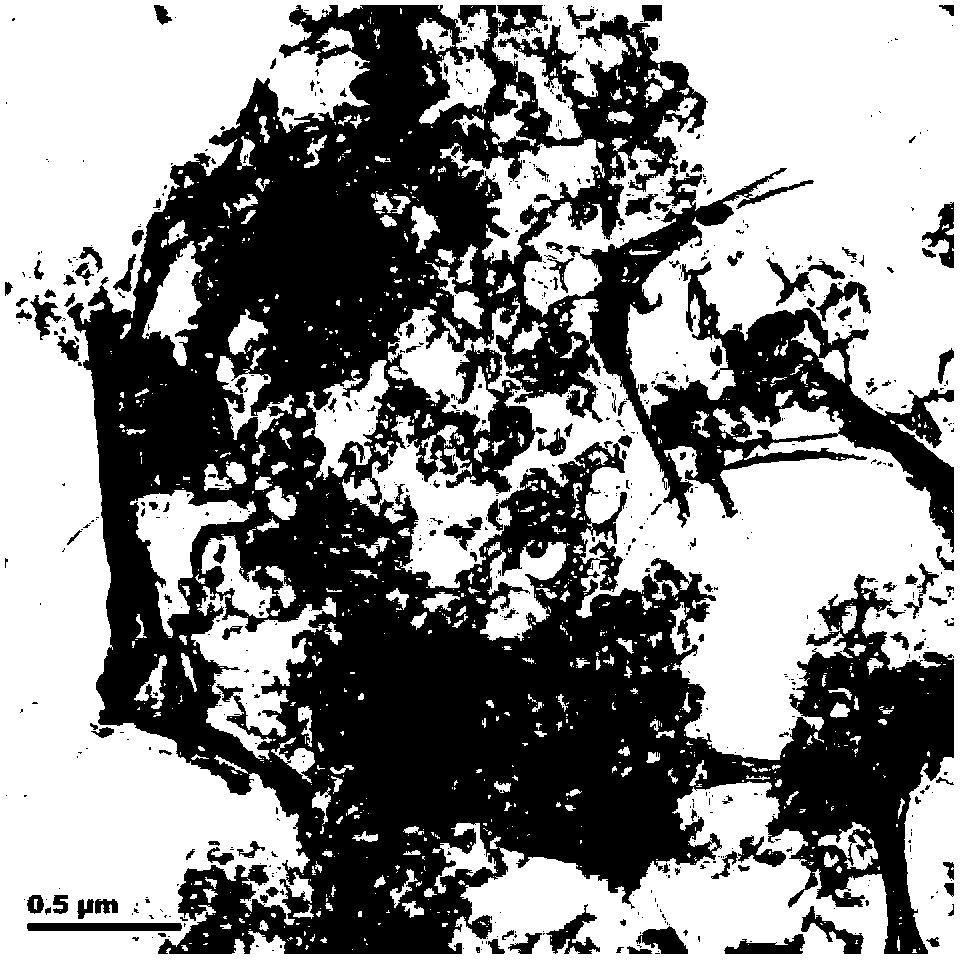

Image

Examples

Embodiment 1

[0019] Disperse 6 mg of graphite oxide in 200 mL of deionized water by ultrasonic treatment, ultrasonic for 3 h, and centrifuge to obtain a stable graphene oxide suspension in the upper layer with a concentration of 0.03 mg / mL. Add 1.82g of CTAB to the suspension, and stir thoroughly to dissolve CTAB in the graphene oxide suspension; add 0.55mL of pyrrole to it, and stir for 2h at 0~4°C, so that pyrrole is fully adsorbed on the graphene oxide nanosheets . Dissolve 1.83g of APS and 1.73g of citric acid in 50mL of deionized water, then slowly add the solution to the above reaction system, pyrrole begins to oxidatively polymerize to form polypyrrole, and the reactants are kept stirring at 0~4°C 5h. The obtained product was washed several times with absolute ethanol and deionized water, suction filtered, and vacuum-dried at 60°C for 5 hours to obtain a graphene oxide / conductive polypyrrole nanowire composite material, and the mass ratio of graphene oxide to polypyrrole was 1:99. ...

Embodiment 2

[0022] Disperse 10 mg of graphite oxide in 200 mL of deionized water, ultrasonicate for 3 h, and centrifuge to obtain a stable upper layer of graphene oxide suspension with a concentration of 0.05 mg / mL. Then add 1.82g of CTAB to it, and stir thoroughly to dissolve CTAB in the graphene oxide suspension; add 0.55mL of pyrrole to it, and stir for 2h at 0~4°C, so that pyrrole is fully adsorbed on the graphene oxide nanosheets. Dissolve 1.73g of citric acid in 50mL of deionized water, then add 1.83g of APS to it, and stir to dissolve the APS; then slowly add the mixed solution to the above reaction system, pyrrole begins to oxidatively polymerize, and the reactant Stirring was continued at 0~4°C for 5h. The obtained product was washed several times with absolute ethanol and deionized water, filtered with suction, and vacuum-dried at 60°C for 5 hours to obtain a graphene oxide / conductive polypyrrole nanowire composite material. The mass ratio of graphene oxide to polypyrrole was 2:...

Embodiment 3

[0025] Disperse 28mg of graphite oxide in 200mL of deionized water by ultrasonic treatment, sonicate for 3h, and centrifuge to obtain a stable graphene oxide suspension in the upper layer with a concentration of 0.14mg / mL. Add 1.82g of CTAB to the suspension, and stir thoroughly to dissolve CTAB in the graphene oxide suspension; add 0.55mL of pyrrole to it, and stir for 2h at 0~4°C, so that pyrrole is fully adsorbed on the graphene oxide nanosheets . 1.83g of APS and 1.73g of citric acid were dissolved in 50mL of deionized water, and then the mixed solution was slowly added to the above reaction system, and the reactant was continuously stirred at 0~4°C for 5h. The obtained product was washed several times with absolute ethanol and deionized water, suction filtered, and vacuum-dried at 60° C. for 5 h to obtain a graphene oxide / conductive polypyrrole nanowire composite material. The mass ratio of graphene oxide to polypyrrole was 5:95.

[0026] The specific capacitance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com