Warehouse management system and management method

A warehouse management system and technology of warehouse management, applied in the field of warehouse management system and management, can solve the problems of decreased work efficiency, high implementation threshold, and obstacles to warehouse management automation, and achieve the goal of reducing cost threshold, broad market prospects, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and examples of implementation.

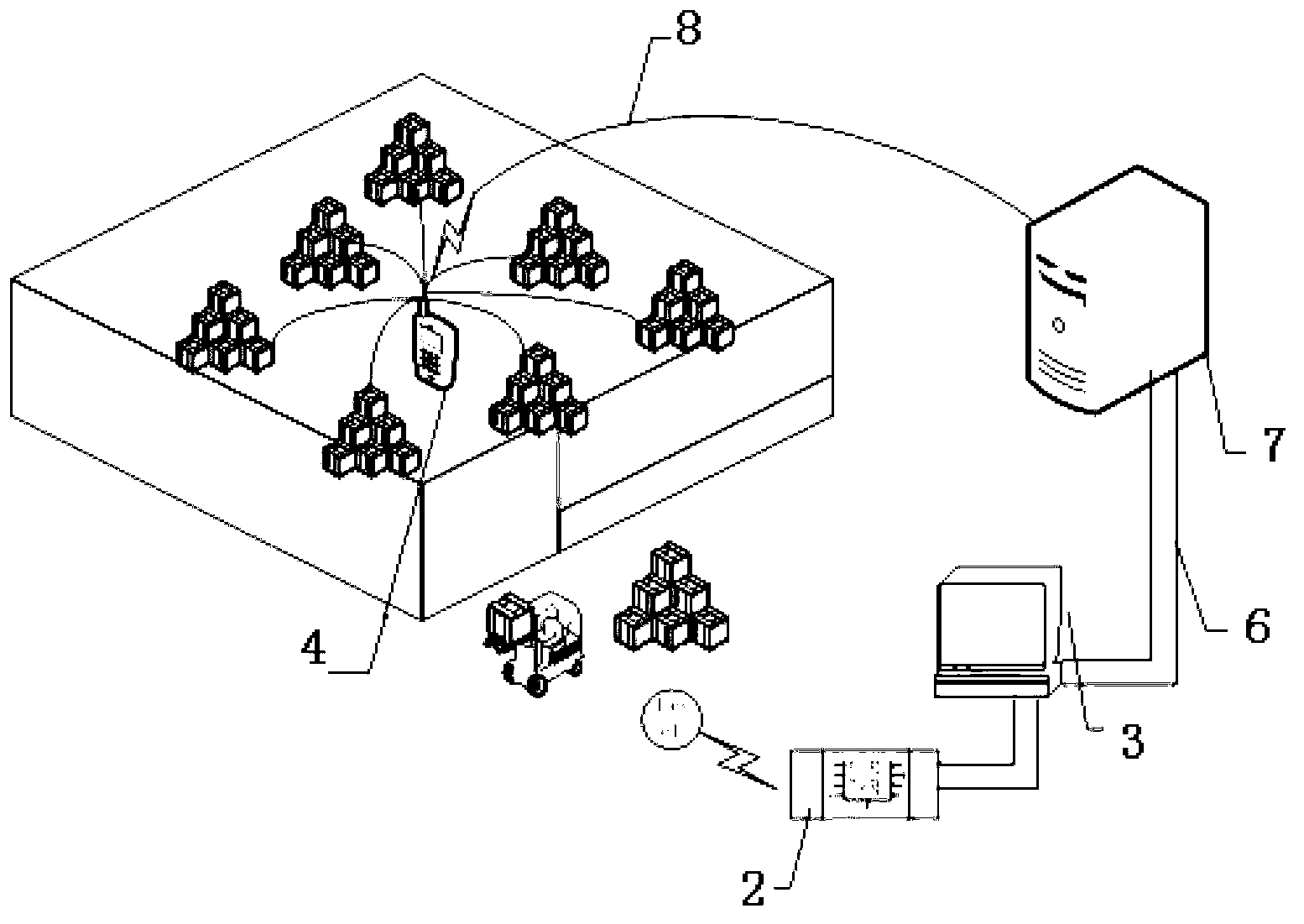

[0053] Such as figure 1 As shown, the present invention includes three parts: input device 1, handheld device 4 and warehouse management server 7, data transmission is carried out through Ethernet 6 between input device 1 and warehouse management server 7, between handheld device 4 and warehouse management server 7 Data transmission takes place via a wireless link 8 .

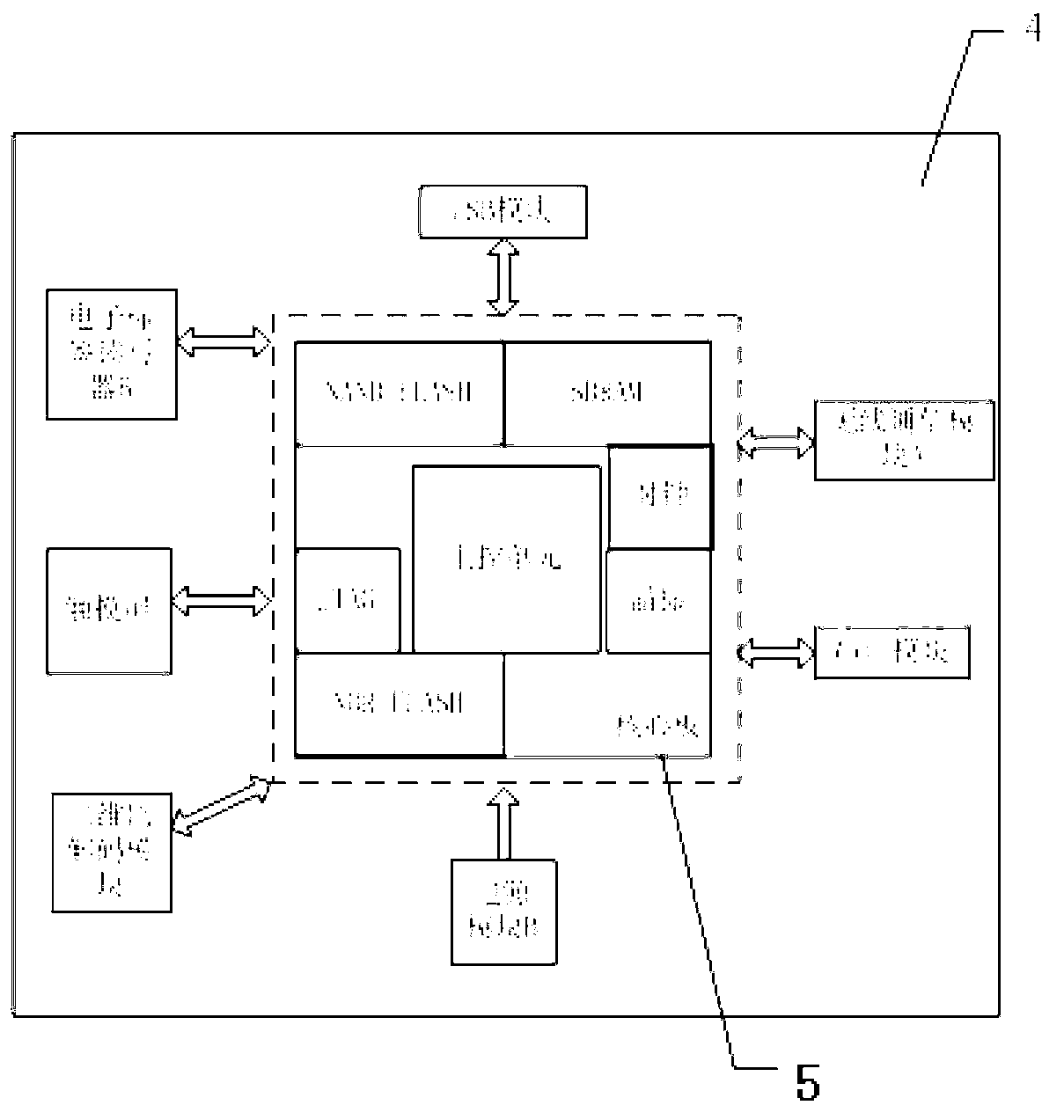

[0054] A warehouse management system, including the following three parts:

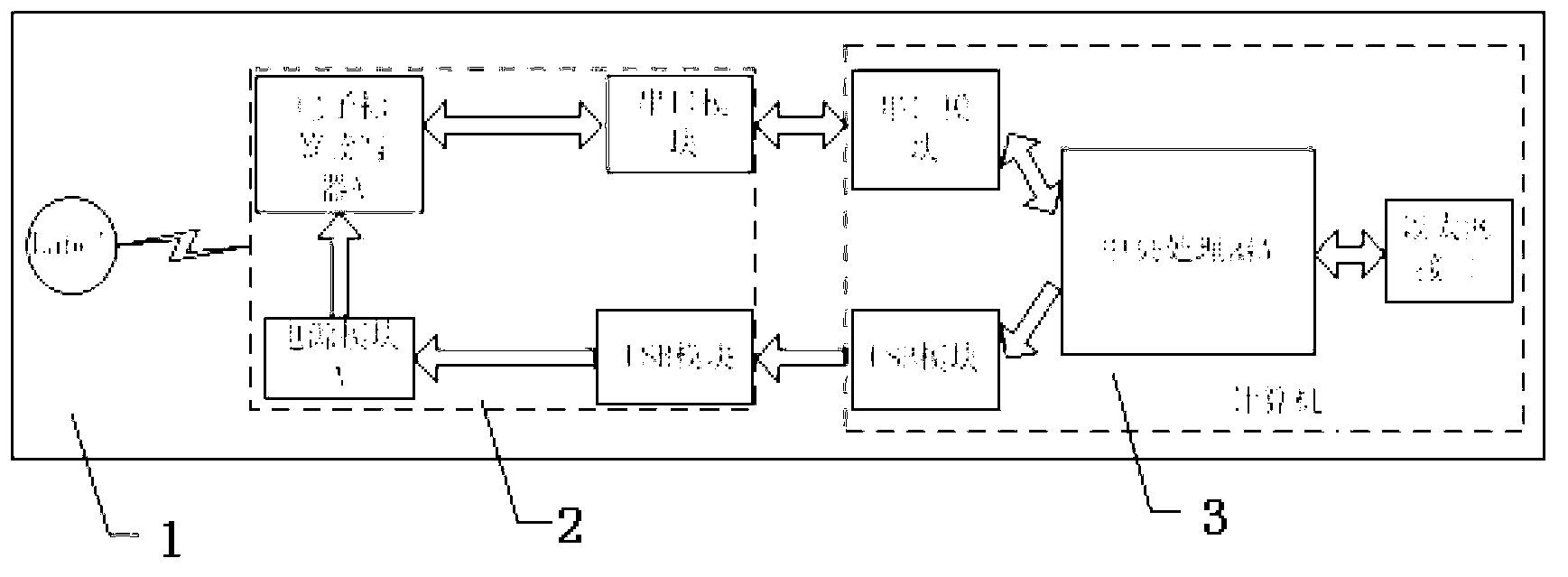

[0055] (1) Input device 1, such as image 3 As shown, including electronic tag reading and writing module 2 and computer 3:

[0056] Electronic label reading and writing module 2: including electronic label reader A, power supply module A, USB module and serial port module, used to read electronic label information through computer control;

[0057] Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com