Water-repellent oil-repellent superfine fiber synthetic leather and preparation method thereof

A superfine fiber, water- and oil-repellent technology, applied in textiles and papermaking, etc., can solve the problems of poor water- and oil-repellent effect, poor water-washing effect, increased energy consumption of products, rust of iron equipment, etc. Water and oil repellent effect, simple process, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

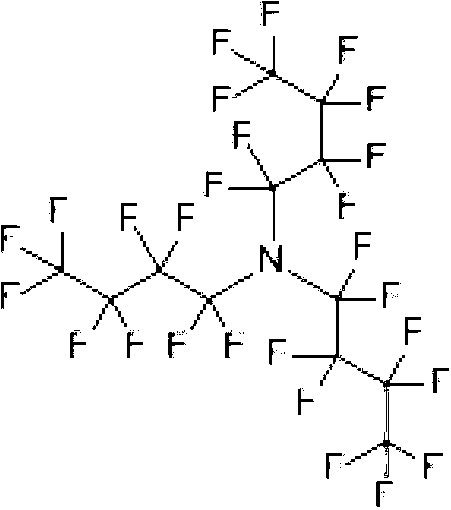

Image

Examples

Embodiment 1

[0031] (1) Dry the superfine fiber synthetic leather through an environment of 50°C at a speed of 0.1 m / s;

[0032] (2) Use compressed air with a pressure of 0.01atm to clean the surface of the dried microfiber synthetic leather to remove impurities such as dust and solid particles on the surface;

[0033] (3) Spray 30 g / m2 of ethanol on the surface of the cleaned microfiber synthetic leather;

[0034] (4) Then apply atmospheric pressure plasma to treat the surface of synthetic leather, the treatment conditions are:

[0035] ①Gas flow rate of plasma generator: 0.05 L / min

[0036] ②The plasma gas is: CF 4 plasma gas

[0037] ③Plasma generator power: 10 watts

[0038] ④Nozzle temperature: 50℃

[0039] ⑤The distance from the nozzle to the treated object: 0.1mm

[0040] ⑥The moving speed of microfiber leather during plasma treatment is: 1mm / min

[0041] The superfine fiber synthetic leather after the above treatment has a good water repelling effect, and the contact angle o...

Embodiment 2

[0043] (1) Dry the microfiber synthetic leather through an environment of 130°C at a speed of 12 m / s;

[0044] (2) Use compressed air with a pressure of 0.3atm to clean the surface of the dried microfiber synthetic leather to remove impurities such as dust and solid particles on the surface;

[0045] (3) Spray 10 g / m2 of C5-18-perfluoroalkane on the surface of the cleaned microfiber synthetic leather;

[0046] (4) Then apply atmospheric pressure plasma to treat the surface of synthetic leather, the treatment conditions are:

[0047] ①Gas flow rate of plasma generator: 0.5 L / min

[0048] ②Plasma gas: CF 4 Plasma Gas and CH 2 CF 2 Plasma gas gas mixture, volume ratio: 1:1

[0049] ③Plasma generator power: 500 watts

[0050] ④Nozzle temperature: 120℃

[0051] ⑤The distance from the nozzle to the treated object: 6mm

[0052] ⑥The moving speed of microfiber leather during plasma treatment: 2m / min

[0053] The superfine fiber synthetic leather after the above treatment has a ...

Embodiment 3

[0055] (1) Dry the superfine fiber synthetic leather through an environment of 160°C at a speed of 20 m / s;

[0056] (2) Use compressed air with a pressure of 0.5 atm to clean the surface of the dried microfiber synthetic leather to remove impurities such as dust and solid particles on the surface;

[0057] (3) Spray 30 g / m2 of perfluoroalkyl iodide on the surface of the cleaned microfiber synthetic leather;

[0058] (4) Then apply atmospheric pressure plasma to treat the surface of synthetic leather, the treatment conditions are:

[0059] ①Gas flow rate of plasma generator: 10 liters / minute

[0060] ②Plasma gas is CH 2 CF 2

[0061] ③Plasma generator power: 1000 watts

[0062] ④Nozzle temperature: 160℃

[0063] ⑤The distance from the nozzle to the treated object: 10mm

[0064] ⑥The moving speed of microfiber leather during plasma treatment: 5m / min

[0065] The superfine fiber synthetic leather after the above treatment has a good oil repelling effect, and the contact a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com