Polycrystalline silicon ingot, manufacturing method thereof, solar cell

A technology of polycrystalline silicon ingots and manufacturing methods, which is applied in the direction of polycrystalline material growth, chemical instruments and methods, circuits, etc., can solve the problems of low photoelectric conversion efficiency, low minority carrier lifetime, and small crystal grains, and achieve high photoelectric conversion efficiency and reduce The effect of oxygen impurity content and low attenuation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

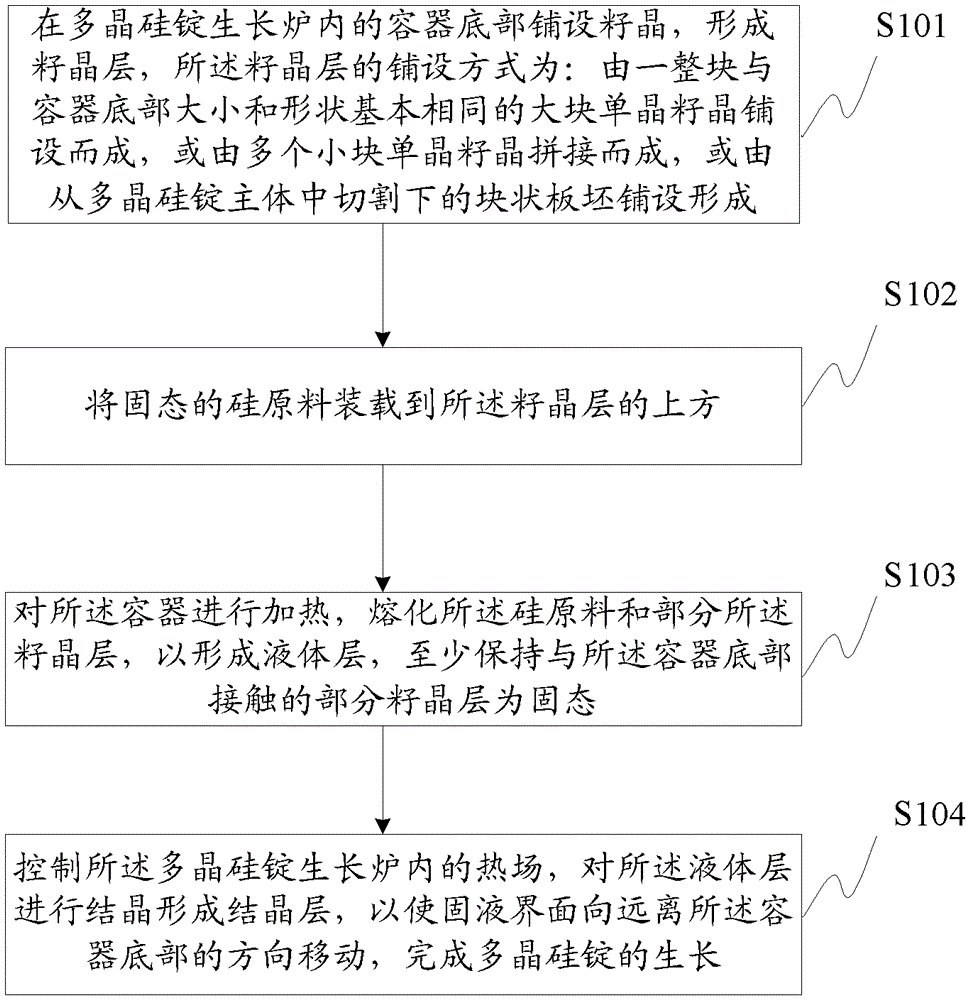

[0062] Based on the above research, an embodiment of the present invention provides a method for manufacturing a polycrystalline silicon ingot, the flow chart of the method is as follows figure 1 shown, including the following steps:

[0063] Step S101: laying seed crystals on the bottom of the container in the polycrystalline silicon ingot growth furnace to form a seed crystal layer, wherein the seed crystal layer is a bulk single crystal seed crystal that is substantially the same size and shape as the bottom of the container, or formed by Multiple small single crystal seed crystals spliced together;

[0064] Wherein, the seed crystal is single crystal silicon with a fixed crystallographic orientation, and the seed layer includes at least one single crystal silicon layer with crystallographic orientation. Preferably, the seed crystals in this embodiment are (100), ( 110) or (111) oriented single crystal silicon.

[0065] Specifically, in this embodiment, the seed layer i...

Embodiment 2

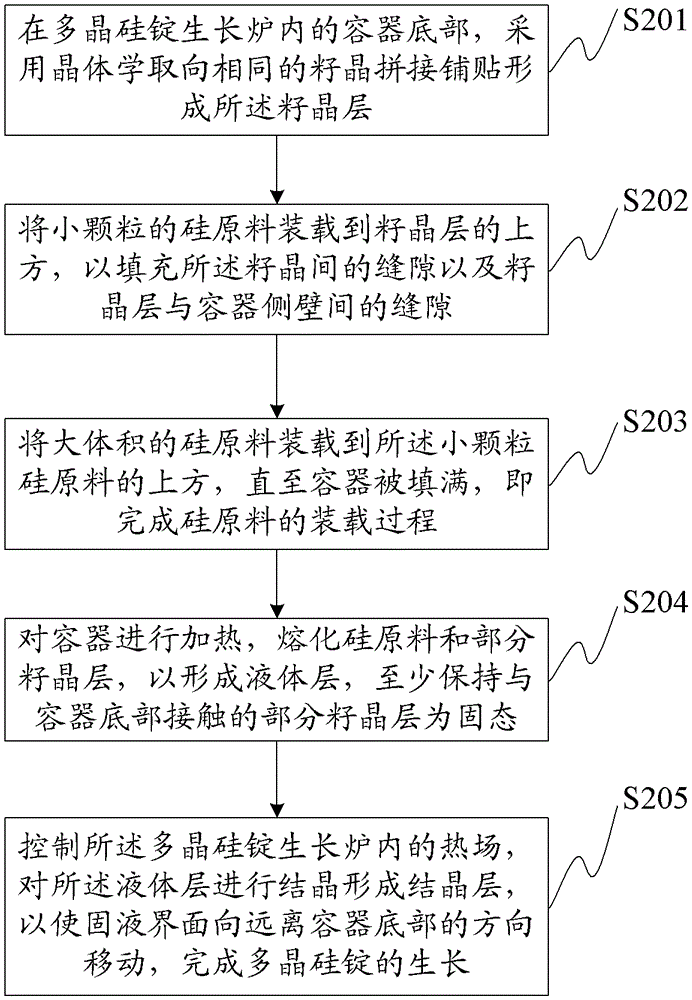

[0083] The flow chart of the casting method of the polycrystalline silicon ingot disclosed in this embodiment is as follows: figure 2 As shown, the difference from the previous embodiment is that in this embodiment, the selection of the seed crystal, the formation method of the seed layer and the process of loading silicon raw materials are embodied, and the method includes the following steps:

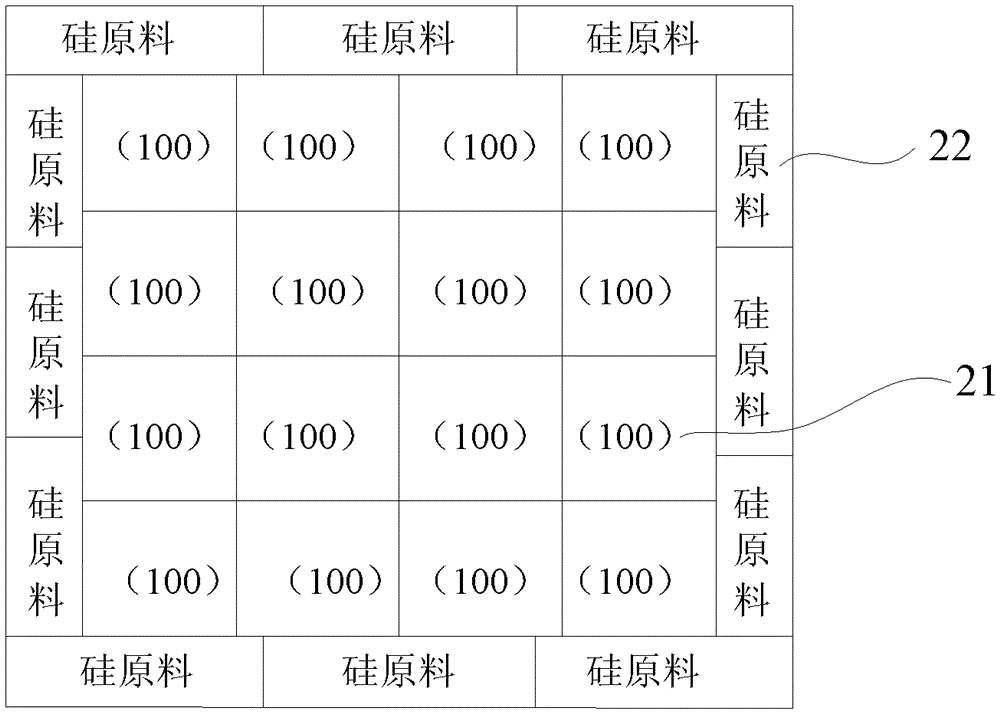

[0084] Step S201: at the bottom of the container in the polycrystalline silicon ingot growth furnace, the seed crystal layer is formed by splicing and tiling seed crystals with the same crystallographic orientation, and the seed crystal layer is substantially parallel to the bottom of the container;

[0085] In this embodiment, the seed layer is preferably formed by paving (100)-oriented single crystal silicon. Preferably, the area of the seed layer accounts for the percentage of the bottom area of the container, that is, the area of the seed layer is The area accounts for 50%-...

Embodiment 3

[0093] The difference from the previous embodiment is that the laying method of the seed layer and the selection of the seed crystal in this embodiment are different, and the crystallographic orientation of the seed crystal in this embodiment is different. The flow chart of the casting method of the polycrystalline silicon ingot disclosed in this embodiment is as follows: Figure 5 As shown, the method includes the following steps:

[0094] Step S301: splicing and paving seed crystals with the first crystallographic orientation to cover part of the bottom area of the container to form a seed crystal region with the first crystallographic orientation;

[0095] Step S302: using a seed crystal with a second crystallographic orientation to cover part of the bottom area of the container to form a seed crystal region with a second crystallographic orientation, the seed crystal region with a first crystallographic orientation and the seed crystal region with a first crystallograp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com