Preparation method of refined silver tin oxide crystal grain

A tin oxide and silver refining technology is applied in the field of preparation of refined silver tin oxide crystal grains, which can solve the problems of poor compactness, poor processing performance, low material strength, etc., so as to reduce the risk of persistent oxidation and prevent melting Good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

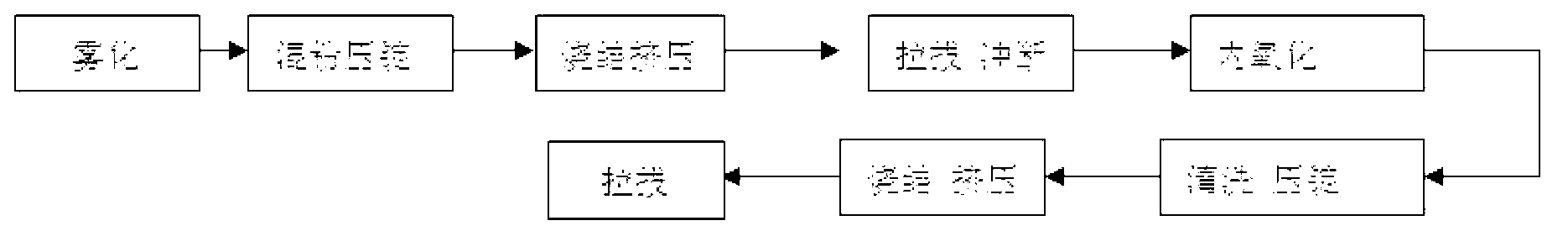

Method used

Image

Examples

Embodiment 1

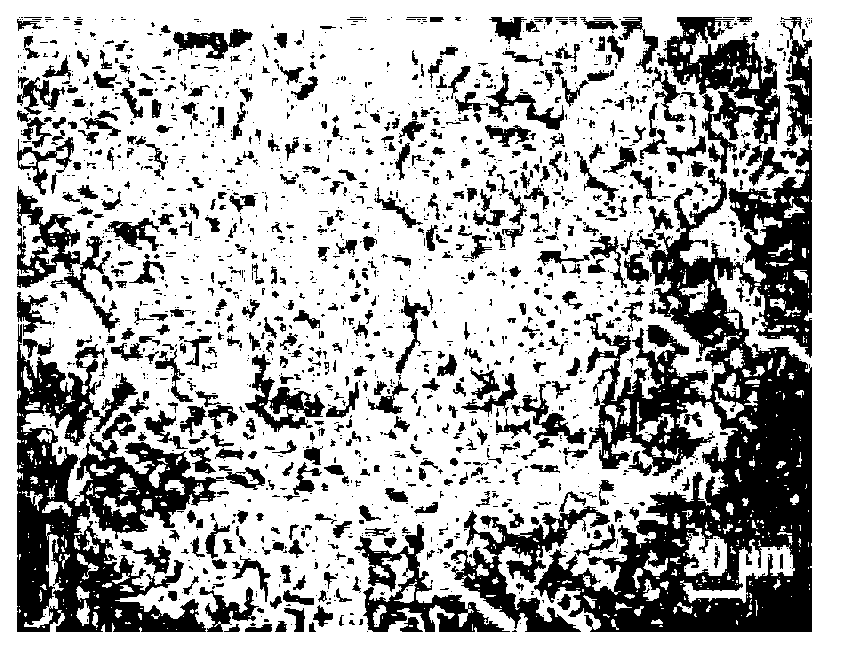

[0035] 99.99% silver plates, 99.5% Sn ingots, 99.97% In, 99.9% Cu ingots are alloyed in an intermediate frequency furnace in a weight ratio of 86:7:6:1 and atomized into AgSn powder by 30MPa water pressure , through a 300-mesh sieve, and add 1% MoO to the under-sieve 3 and 0.2% Bi 2 o 3 Mix the powder in the three-dimensional powder mixer for 2 hours, and press the mixed powder in the isostatic press at 100Ma for 30s to obtain a spindle with a diameter of 95mm-105mm, which is extruded into an AgSn alloy wire with a diameter of 5mm in a diameter of 110mm, and drawn After pulling to a diameter of 2.0mm, punch the wire to a length of 15mm-30mm, and oxidize it for 5 hours under the oxidation process parameters of 200°C-250°C, and oxidize for 20 hours at 700°C-750°C, with an oxygen pressure of 2MPa throughout the process; judge the port oxidation After completion, wash the oxidized wire in the drum for half an hour, anneal at 830°C-870°C for 1 hour-1.5 hours, press it into an ing...

Embodiment 2

[0040] 99.99% silver plates, 99.5% Sn ingots, 99.9% Bi ingots, and 99.9% Cu ingots are alloyed in an intermediate frequency furnace in a weight ratio of 95:2.2:2.3:0.5, and then atomized into AgSn by 30MPa hydraulic pressure. Alloy powder, pass through 200 mesh sieve, add 0.5% WO to the undersieve 3 , 1.5%In 2 o 3 and 0.2MoO 3 % Mix the powder in a three-dimensional powder mixer for 2 hours, press the mixed powder in an isostatic press at 100Ma for 30s, obtain a spindle with a diameter of 95mm-105mm, and extrude it into an AgSn alloy wire with a diameter of 5mm in a diameter of 110mm. After being drawn to a diameter of 1.2mm, the wire is punched to a length of 15mm-30mm, oxidized for 1.0 hour at the oxidation process parameter of 450°C-500°C, raised to 800°C-850°C, oxidized for 30 hours, and the oxygen pressure of the whole process is 0.6MPa ; After judging that the port is completely oxidized, wash the oxidized wire in the drum for half an hour, anneal at 830°C-870°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com