Method for preparing xylitol and its intermediate D-xylosone by microbial transformation of glucose and strain used in the same

A technology of microbial transformation and Gluconobacter oxidans, applied in the field of xylitol intermediates, can solve the problems of low efficiency of arabitol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

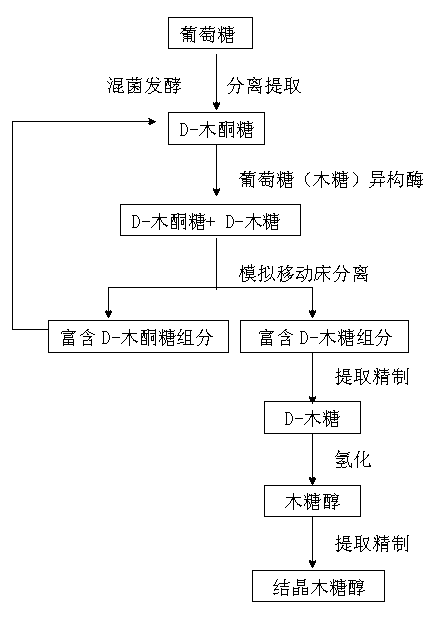

Method used

Image

Examples

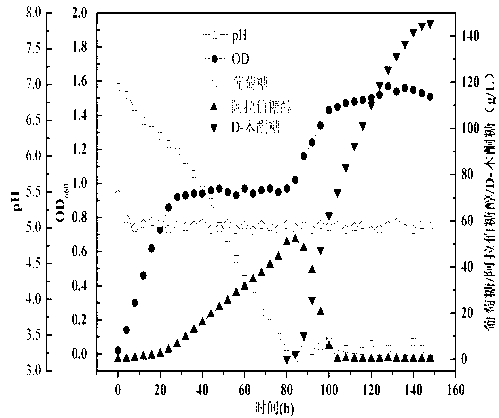

Embodiment 1

[0054] (1) Medium: The composition of seed medium A is: glucose 80 g / L, corn steep liquor 10 g / L, yeast extract 3 g / L, MgSO 4 0.5 g / L, natural pH; composition of seed medium B: arabitol 120 g / L, yeast extract 10 g / L, calcium carbonate 1.5 g / L, pH 5.2; fermentation medium composition: glucose 160 g / L L, corn steep liquor 10 g / L, yeast extract 3 g / L, KH 2 PO 4 3 g / L, MgSO 4 0.5 g / L, pH 5.0.

[0055] (2) Seed liquid preparation: a) Kodamaea ohmeri TL-1123 seed liquid: Take a ring of bacteria from the slope and inoculate it in a shaker flask (medium A), with a liquid volume of 15%, 250 rpm , cultivated at 35°C for 16 h as the seed solution of the yeast shake flask (that is, the first-grade seed solution, the same below), and then inoculated the yeast shake flask seed solution into the 100 L fermenter seed solution (medium A) according to the inoculum amount of 10%. , with a liquid volume of 60%, an aeration ratio of 0.5 L / L min, 150 rpm, and expanded culture at 35°C for 14 ...

Embodiment 2

[0063] (1) Medium: The composition of seed medium A is: glucose 70 g / L, corn steep liquor 8 g / L, yeast extract 4.5 g / L, MgSO 4 0.9 g / L, natural pH; composition of seed medium B: arabitol 110 g / L, yeast extract 7 g / L, calcium carbonate 1.2 g / L, pH 5.1; fermentation medium composition: glucose 150 g / L L, corn steep liquor 8 g / L, yeast extract 4 g / L, KH 2 PO 4 3.5 g / L, MgSO 4 0.9 g / L, pH 5.3.

[0064] (2) Seed solution preparation: a) Kodamaea ohmeri TL-1123 seed solution: Take a ring of bacteria from the slope and inoculate it in a shaker flask (medium A), with a liquid volume of 15%, 180 rpm , cultured at 33°C for 18 h as the yeast shake flask seed solution, and then inoculated the yeast shake flask seed solution in a 100 L fermenter seed solution (medium A) according to the inoculum volume of 15%, with a liquid volume of 60% and an aeration ratio of 0.8 L / L min, 100 rpm, expanded culture at 33°C for 12 h as yeast expansion seed solution; b) Gluconobacter oxidans seed so...

Embodiment 3

[0072] (1) Medium: Seed medium A is: glucose 60 g / L, corn steep liquor 5 g / L, yeast extract 5 g / L, MgSO 4 1.5 g / L, natural pH; composition of seed medium B: arabitol 100 g / L, yeast extract 5 g / L, calcium carbonate 0.5 g / L, pH 5.4; fermentation medium composition: glucose 120 g / L L, corn steep liquor 5 g / L, yeast extract 5 g / L, KH 2 PO 4 4 g / L, MgSO 4 1.5 g / L, pH 5.5.

[0073] (2) Seed solution preparation: a) Kodamaea ohmeri TL-1123 seed solution: Take a ring of bacteria from the slope and inoculate it in a shaker flask (medium A), with a liquid volume of 15%, 100 rpm , cultivated at 30°C for 20 h as yeast shake flask seed solution, and then inoculated the yeast shake flask seed solution in a 100 L fermenter seed solution (medium A) according to the inoculum amount of 5%, with a liquid volume of 60% and an aeration ratio of 0.3 L / L min, 200 rpm, 30°C expanded culture for 20 h as yeast expansion seed solution; b) Gluconobacter oxidans seed solution: all colonies were elu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com