Spherical magnesium halide adduct and preparation method and application thereof

A technology of adducts and magnesium halides, applied in the direction of magnesium organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

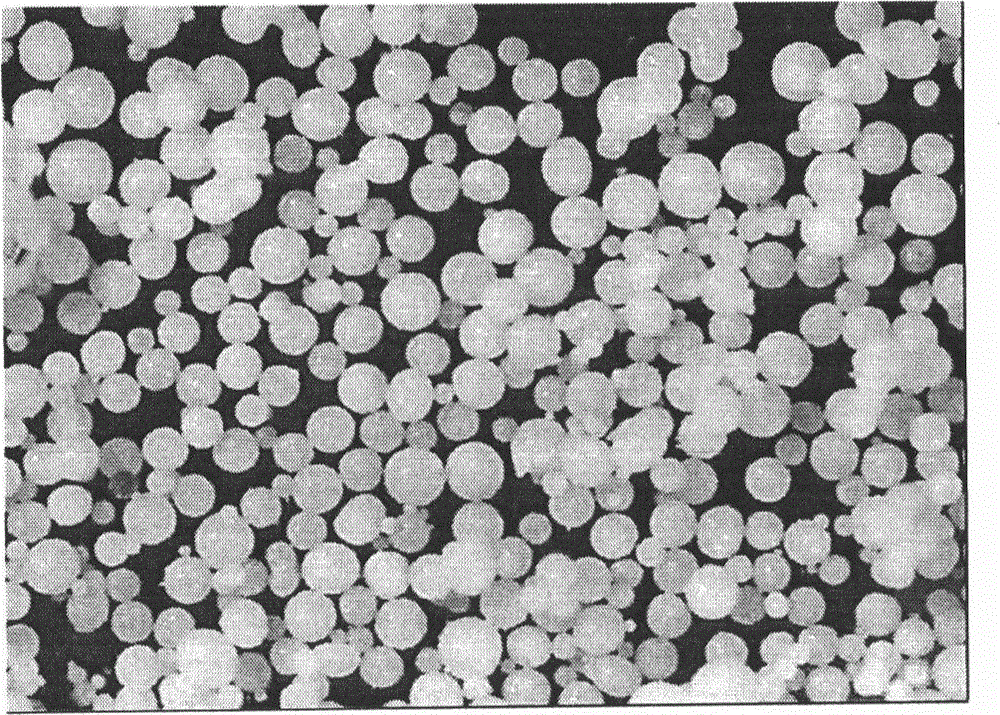

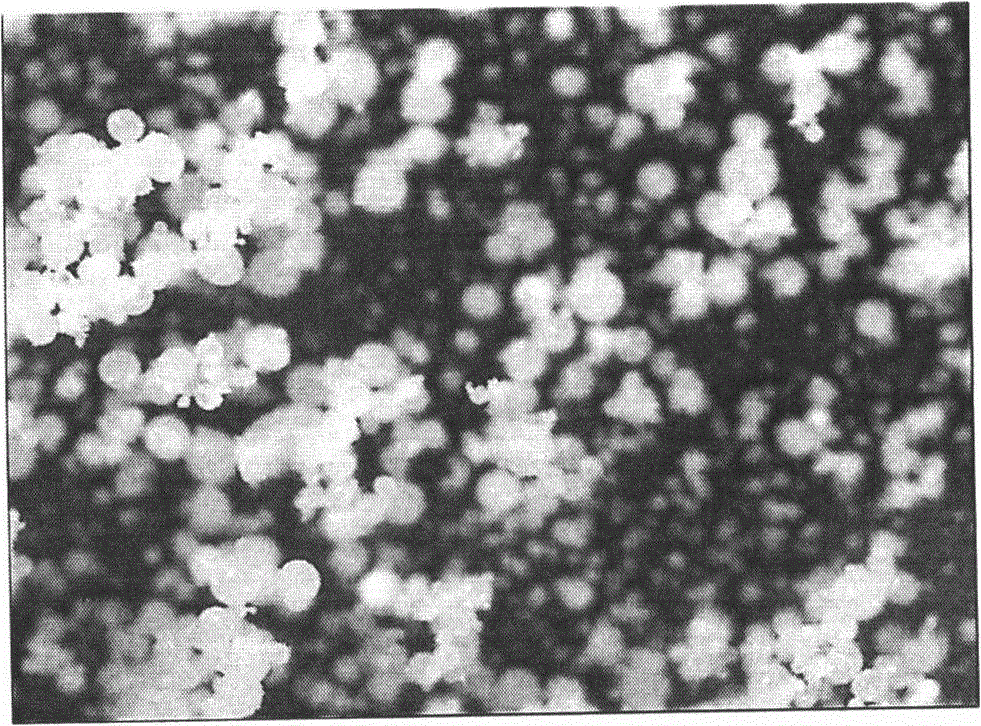

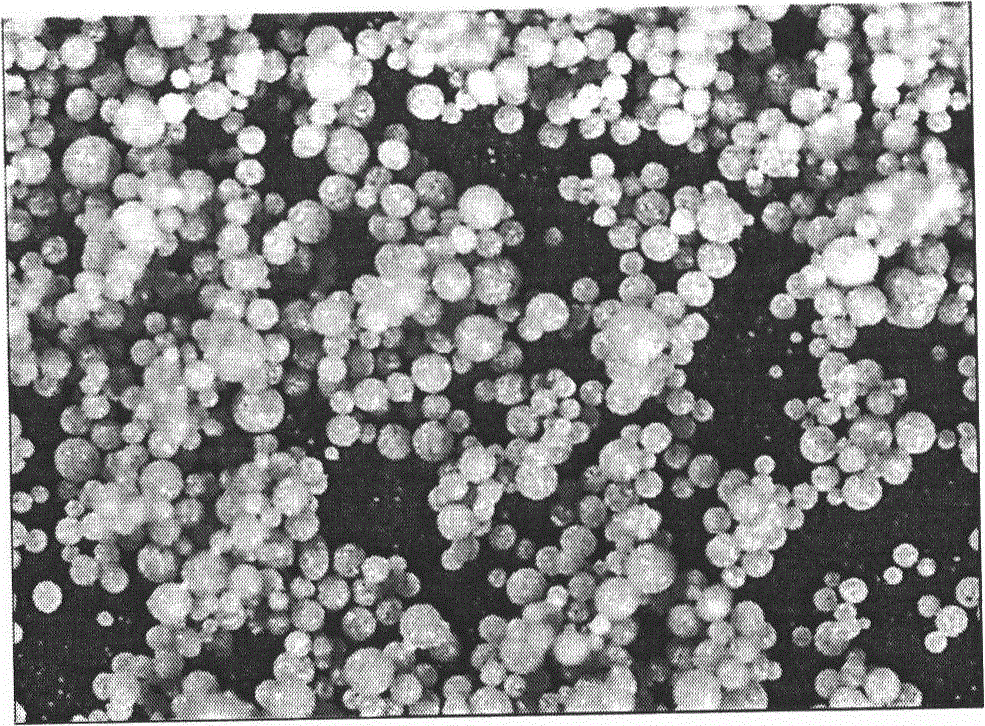

Image

Examples

Embodiment approach

[0028] According to one embodiment of the present invention, the general formula of the magnesium halide adduct can be expressed as MgXY-mROH-nCH 3 OH-tDOE-qH 2 O, wherein, in MgXY, X is a halogen, Y can be a halogen, C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 The aryloxy group; in ROH, R can be C 2 -C 12 Alkyl, C 3 -C 10 Cycloalkyl or C 6 -C 10 Aryl group; m is 1-2.4, n is 0.1-1.0, t is 0.0001-0.1, q is 0-0.8; in the preferred case, in the above general formula of magnesium halide adduct, m is 1.5-2.2 , n is 0.3-0.8, t is 0.0002-0.01, q is 0-0.5.

[0029] In the present invention, in the general formula MgXY, both X and Y are halogen, or X is halogen, and Y can be C 1 -C 6 Alkyl, C 1 -C 6 Alkoxyl, C 6 -C 12 Aryl or C 6 -C 12 of aryloxy groups. The halogen is preferably chlorine or bromine. The C 1 -C 6 The alkyl group can be, for example, methyl, ethyl, propyl, isopropyl, butyl or isobutyl, and the C 1 -C 6 The alkoxy group can...

Embodiment 1

[0053] This example is used to illustrate the magnesium halide adduct provided by the present invention and its preparation method and application.

[0054] (1) Preparation of magnesium chloride adduct

[0055] In a 300L autoclave, add 90L of white oil, 90L of silicone oil, 9.0kg of magnesium chloride (94.7mol) and 14.5L of ethanol (249.0mol), raise the temperature to 125°C under stirring, and stir at 125°C for 2.5 hours, then, the resulting mixed liquid was passed through a high-gravity rotating bed into hexane pre-cooled to -30°C, the liquid was filtered off, washed five times with hexane, and then vacuum-dried at 40°C for 2 hours to obtain 18 kg of Solid material (i.e. alcoholate of magnesium chloride).

[0056] In a 1.6L reactor, add 900ml of hexane, add 90 grams of the solid matter prepared above, and then dissolve 45ml of dimethoxypropane solution (dimethoxypropane in 180ml of hexane) content of 0.37mol) was added therein, then, the temperature was raised to 60°C, and ...

Embodiment 2

[0063] This example is used to illustrate the magnesium halide adduct provided by the present invention and its preparation method and application.

[0064] The magnesium chloride adduct was prepared, the olefin polymerization catalyst was prepared, and the propylene polymerization was carried out according to the method of Example 1, except that the amount of hydrogen added during the propylene polymerization was 6.5 L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com