Method for separating m-ethyltoluene and p-ethyltoluene by extractive distillation

A technology for extractive distillation and p-toluene ethylbenzene, which is used in distillation purification/separation, organic chemistry, etc., can solve the problems of slow decomposition, low separation efficiency of m-ethyl benzene and p-toluene ethylbenzene, and increased solvent consumption, so as to improve the relative volatilization The effect of high purity, high product purity and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

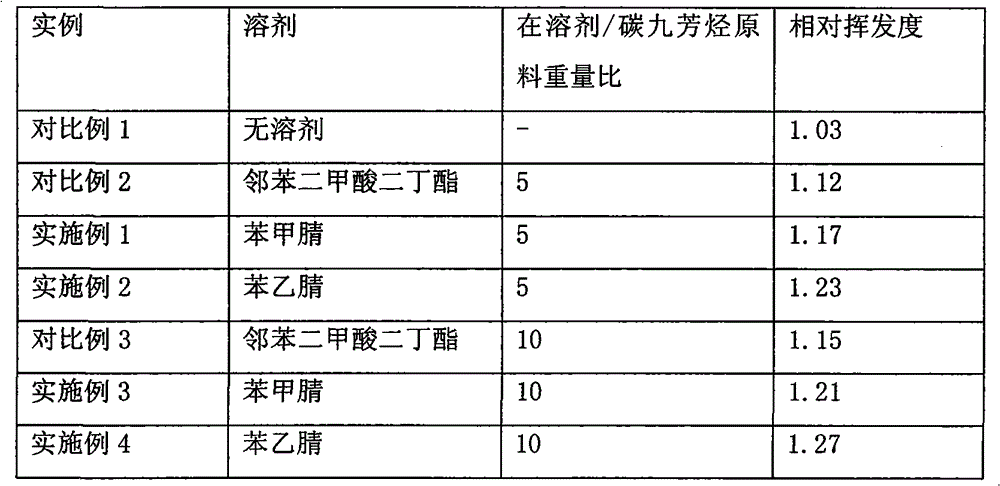

[0026] Under the condition that the mixture weight ratio of solvent / m-methylethylbenzene and p-methylethylbenzene is 5 and 10, the extraction and rectification solvent benzonitrile and phenylacetonitrile have been tested as described above, and the experimental results of their relative volatility are listed in Table 1 .

Embodiment 5

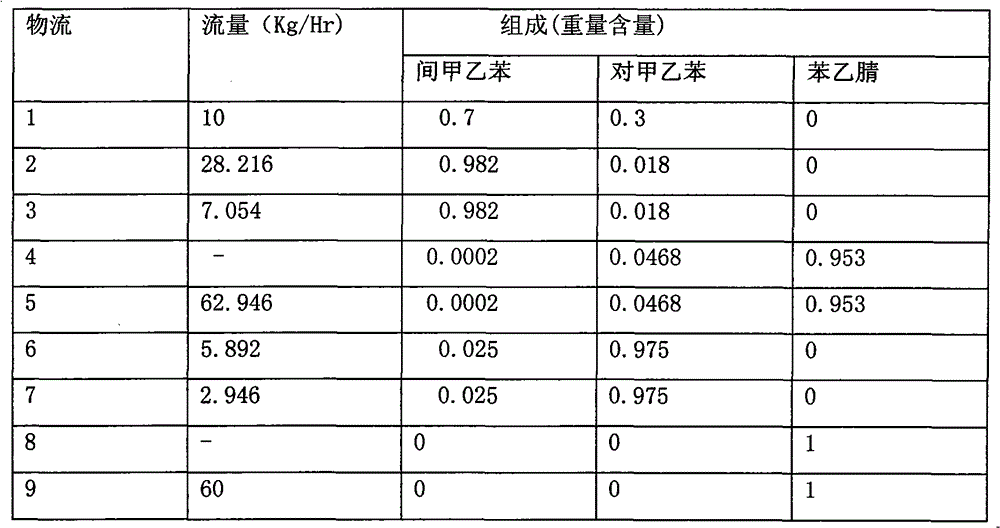

[0033] The raw material is a mixture of m-methylethylbenzene and p-methylethylbenzene, which contains 70% (weight) of m-methylethylbenzene and 30% (weight) of p-methylethylbenzene. The separation process conditions of embodiment 5 and each stream are listed in table 2 and 3 respectively. The extraction and rectification solvent adopts phenylacetonitrile.

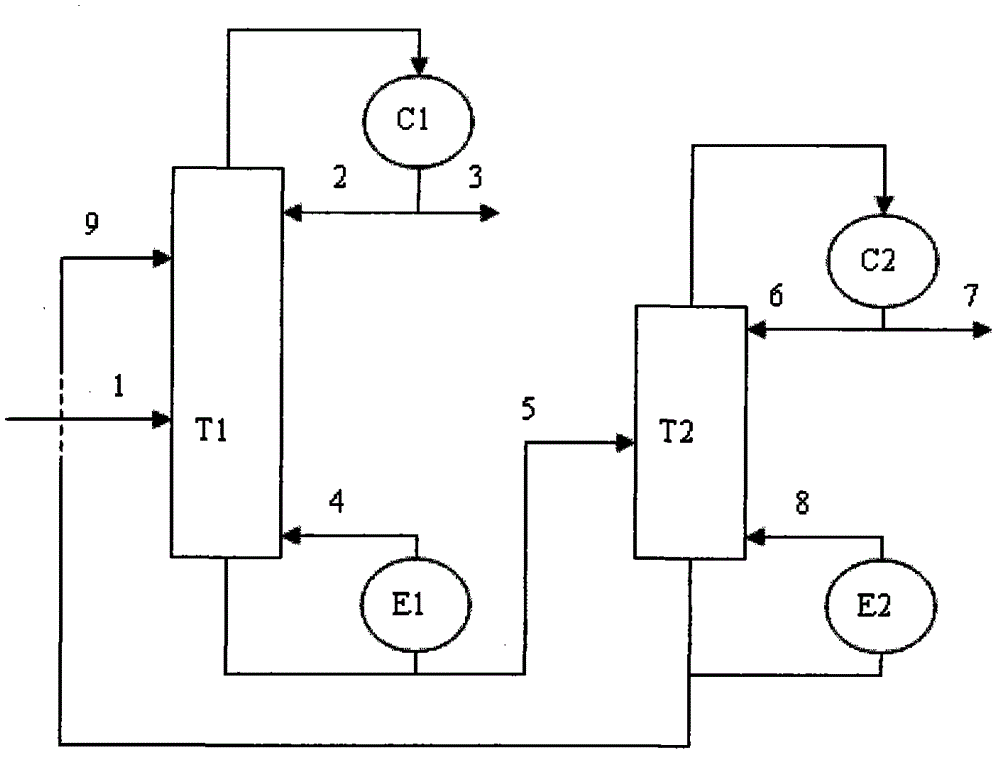

[0034] Such as figure 1 As shown, the raw material 1 containing the mixture of m-methylethylbenzene and p-methylethylbenzene enters the middle and lower part of the extractive distillation tower T1, and the circulating extractive distillation solvent 9 enters the extractive distillation tower T1 from the upper part, and is separated by extractive rectification, and distilled out from the top of the tower. Methylethylbenzene, after being cooled by the first cooler C1, a part flows into the top of the extractive distillation tower T1 as methylethylbenzene reflux 2, and another part then discharges as product mmethylethylbenze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com