High surface area far infrared material, and preparation method and application thereof

A high-surface-area, far-infrared technology, applied in the field of chemical materials, can solve the problems of far-infrared release performance fluctuations, limited application range, and few sources of jade, and achieve the effects of improving drug absorption speed, deterministic process parameters, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high surface area far-infrared material is prepared by the following process,

[0031] 1) Mixing and crushing of raw materials

[0032] Get 75g of aluminum oxide, 10g of iron oxide, 1g of zinc oxide, 5g of cobalt oxide, 4g of nickel oxide, 2g of manganese oxide, and 3g of copper oxide according to the weight percentage of raw materials, and put them in a ball mill for ball milling. The ball mill speed for mass production is 600 revolutions per minute. Maintain for 4 hours, the output particle size is 5-10 microns, and the mixed fine material is obtained.

[0033] 2) Sintering

[0034] The mixed fine material is sintered, the sintering temperature is increased by 5°C per minute to 800°C, and the time is maintained at 800°C for 4 hours, and the high surface area far-infrared material can be obtained.

Embodiment 2

[0035] Embodiment 2, basic process is the same as embodiment 1, but formula is aluminum oxide 80g, iron oxide 10g, zinc oxide 1g, cobalt oxide 4g, nickel oxide 2g, manganese oxide 2g, copper oxide 1g.

Embodiment 3

[0036] Embodiment 3, the basic process is the same as that of Embodiment 1, but the rotating speed of the ball mill is 400 rpm, maintained for 6 hours, and the sintering temperature is increased by 3°C per minute to 900°C, and maintained at 900°C for 2 hours.

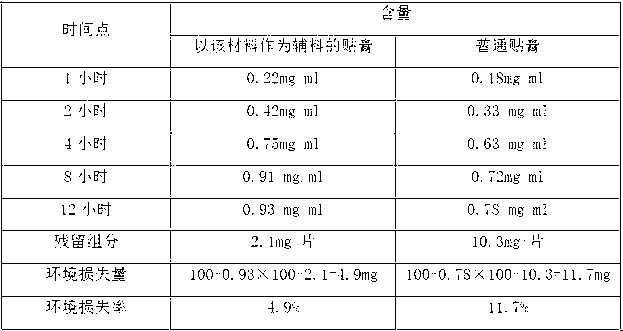

[0037] Adopt embodiment 1 gained high surface area far-infrared ray material to carry out essential oil adsorption test, test method and result are as follows:

[0038] Take this material and 10 grams of ordinary alumina and place them in the same plastic container. After putting them in, scrape the materials flat, and then slowly add sandalwood essential oil to determine the adsorption amount by the incipient wetness method (stop adding essential oils when the surface of the material is just wet) . Results The high specific surface area far-infrared material adsorbed 9.52 grams, while the general alumina was 2.35 grams.

[0039] The results show that this material has good adsorption properties for essential oils.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com