Method for improving uniformity of shallow trench isolation chemical-mechanical planarization

A chemical mechanical and shallow trench technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of silicon oxide abrasion, elimination, and reduction of CMP uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

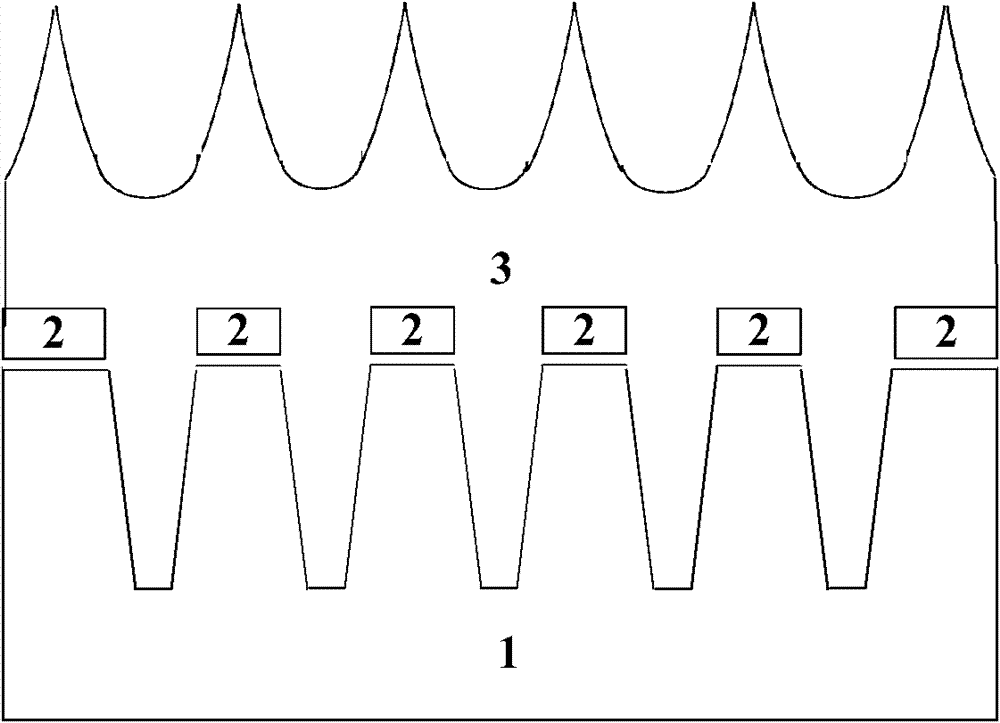

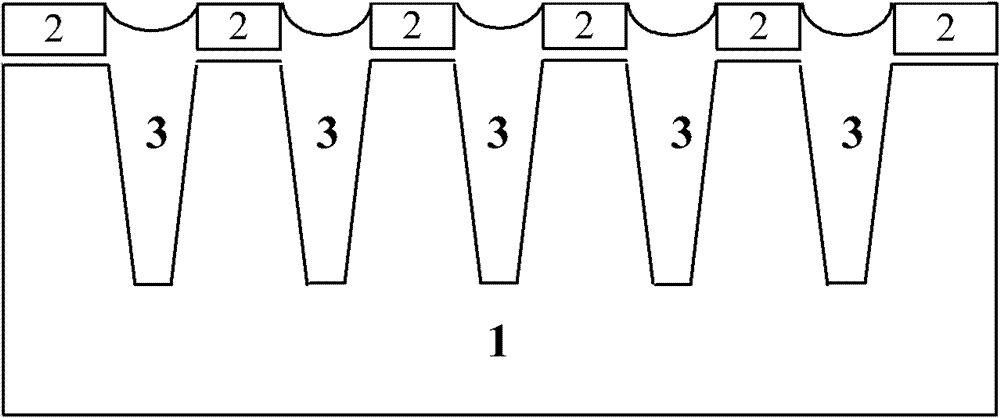

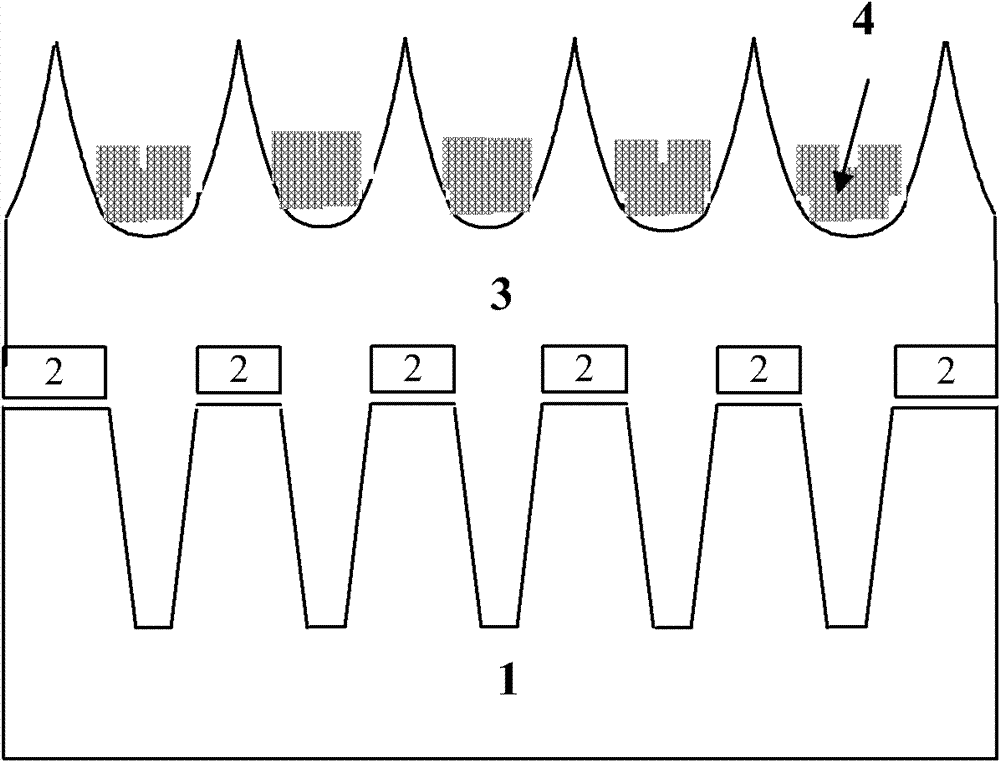

[0021] Figure 3 to Figure 5 A schematic cross-sectional view showing various steps of vertical ion implantation to increase silicon oxide removal rate according to Embodiment 1 of the present invention.

[0022] First refer to image 3 , forming a pad silicon oxide layer and a silicon nitride layer 2 on the substrate 1, photolithography / etching to form a high AR STI, and then using HDP-CVD to fill the high AR STI with silicon dioxide, the filled silicon dioxide and The pad oxide layer is bonded to form a silicon oxide isolation layer 3 . After the silicon oxide isolation layer 3 is deposited, the entire wafer is coated with photoresist; the reverse mask (that is, complementary to the exposure mask used to form STI) with shallow trench isolation is exposed, developed, Expose the silicon oxide in the protruding part of the non-shallow trench area, and retain the photoresist 4 in the concave part, such as image 3 Shown in the grid section.

[0023] Second, refer to Figure...

Embodiment 2

[0027] Figure 6 to Figure 7 A schematic cross-sectional view showing various steps of inclined ion implantation to increase silicon oxide removal rate according to Embodiment 2 of the present invention.

[0028] refer to Image 6, after the silicon oxide isolation layer 3 is deposited, the inclination angle of implantation is firstly determined according to the height H and spacing L of the pattern. In order to ensure that silicon oxide is not implanted in the recess during ion implantation, it is necessary to determine the implantation inclination angle θ, the expression of which is θ≈arctan(H / L), that is, the implantation inclination angle θ is approximately equal to arctan(H / L), where H and L can be obtained by layout design and measurement methods. Specifically, in the present invention, H is the difference in thickness of the silicon oxide layer, which is L is the width of the shallow trench STI, for example After determining the implantation inclination angle, per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com