Resource utilization method for waste lubricating oil

A waste lubricating oil, recycling technology, applied in the direction of lubricating composition, petroleum industry, treatment of hydrocarbon oil, etc., to achieve the effect of reducing dosage, improving conversion rate and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

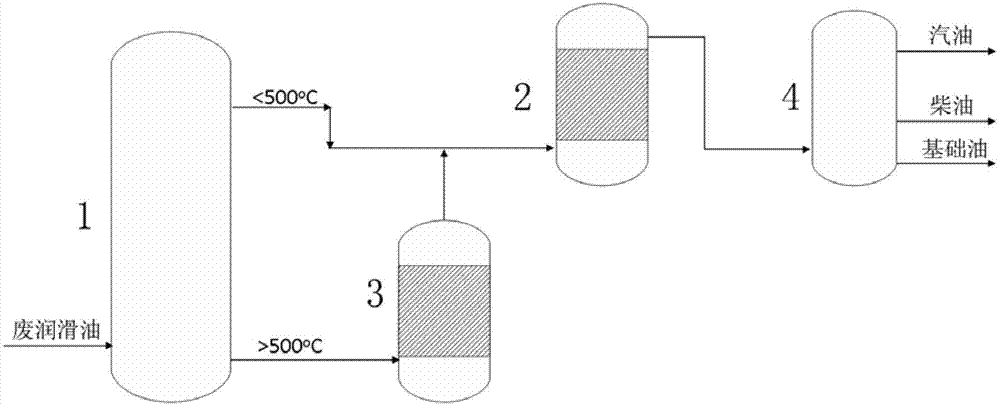

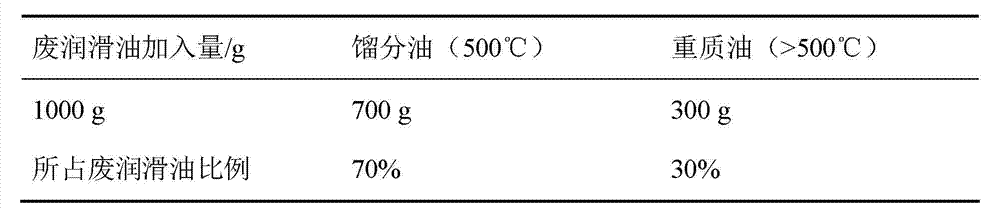

[0025] The raw material waste lubricating oil is injected into the atmospheric distillation tower, and the waste residue and gas generated in the conversion process of the waste engine oil are used for heating. Cut into distillate oil according to distillation temperature ( 500°C). Table 1 below shows the results of atmospheric distillation material balance.

[0026]

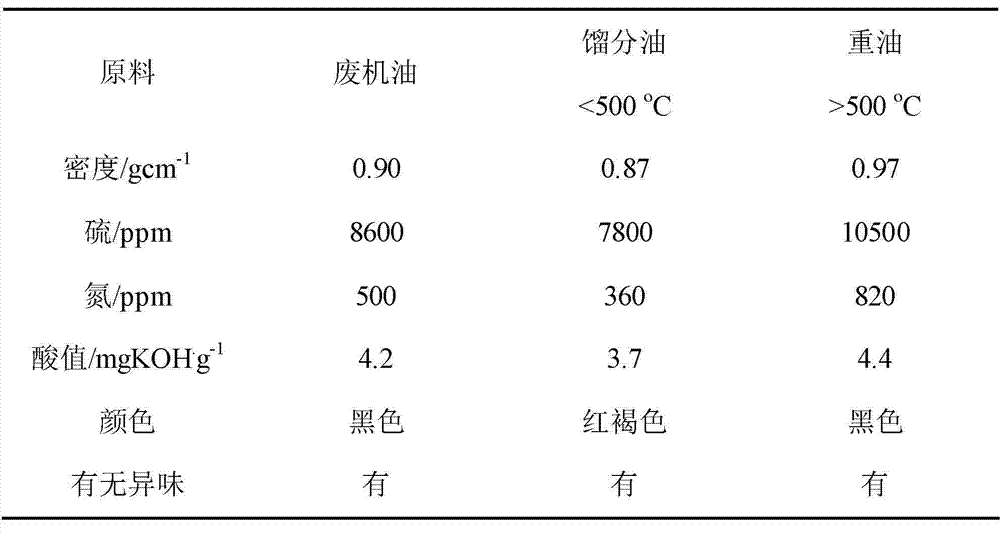

[0027] Table 2 Distillate oil properties before and after atmospheric distillation

[0028]

Embodiment 2

[0030] Gas phase catalytic cracking of heavy oil on molecular sieve / alumina catalyst. The heavy oil is injected into a reactive distillation tower equipped with a molecular sieve / alumina catalyst for reaction and rectification. The catalyst is composed of alumina containing 30% ZSM-5 and 10% β zeolite, and 2.0 is obtained by bonding and molding. -3.0 mm cylindrical product, length 3-8 mm, bulk density 0.65-0.80 g / mL, strength greater than 40 N / mm. The waste residue and fuel gas generated in the conversion process of waste lubricating oil are used for heating, and the ratio of fuel to oil is controlled between 1-20. The generated gas is used to heat the distillation tower. Table 3 below sees the results of the catalytic distillation material balance test.

[0031]

Embodiment 3

[0033] The hydrogenation catalyst adopts a supported nickel molybdenum sulfur catalyst. Carrier uses SiO 2 -Al 2 O 3 , The specific surface area is 200-400 m 2 / g, the pore volume is 0.5-2.0 cm 3 / g, the most probable pore size distribution is 2-4 nm and 10-15 nm. The cobalt molybdenum sulfide precursor uses cobalt nitrate or cobalt acetate or cobalt acetylacetonate and ammonium thiomolybdate. The supported cobalt-molybdenum sulfide catalyst is prepared by adopting the equal volume impregnation method through the steps of impregnation-drying-roasting. Table 4 below sees the reaction process conditions and product composition.

[0034]

[0035] From Table 4, it can be seen that the distillate oil is at 360°C on the supported cobalt-molybdenum sulfide catalyst. o C hydrofining, no diolefins and gums were detected in the product obtained, and the content of sulfur and nitrogen was greatly reduced, indicating that the supported cobalt-molybdenum sulfide catalyst has good desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com