Method for preparing two-component polyurethane corner sealant

A two-component polyurethane and corner glue technology, applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve problems such as slow curing of corner glue, leakage of doors and windows, and proper foaming , to achieve good thixotropy and operability, high bonding and sealing effect, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of two-component polyurethane corner glue, its preferred embodiment comprises steps:

[0019] Prepare the first component:

[0020] Each raw material for preparing the first component is calculated in parts by mass, including:

[0021] Medium molecular weight trifunctional polyether polyol 25~35 parts, small molecular weight trifunctional polyether polyol 3~8 parts, medium molecular weight difunctional polyether polyol 5~10 parts, small molecular weight diol 1~ 3 parts, 50-65 parts of inorganic filler, 2-5 parts of thixotropic agent, 1-3 parts of dehumidifier, 2-5 parts of whitening agent, 1-3 parts of silicone adhesion promoter, 0.01-0.03 parts of catalyst ;

[0022] The above medium molecular weight trifunctional polyether polyol, small molecular weight trifunctional polyether polyol, small molecular weight diol, medium molecular weight difunctional polyether polyol, inorganic filler, thixotropic agent, dehumidifier, whitening After the agent...

Embodiment 1

[0047] The first embodiment provides a method for preparing a two-component polyurethane corner glue. The prepared two-component polyurethane corner glue has the characteristics of fast curing speed, excellent bonding performance, and good sealing performance. It is used for heat insulation (broken bridge) corner joints and corner joints of aluminum alloy doors and windows. The preparation method specifically includes:

[0048] Prepare the first component:

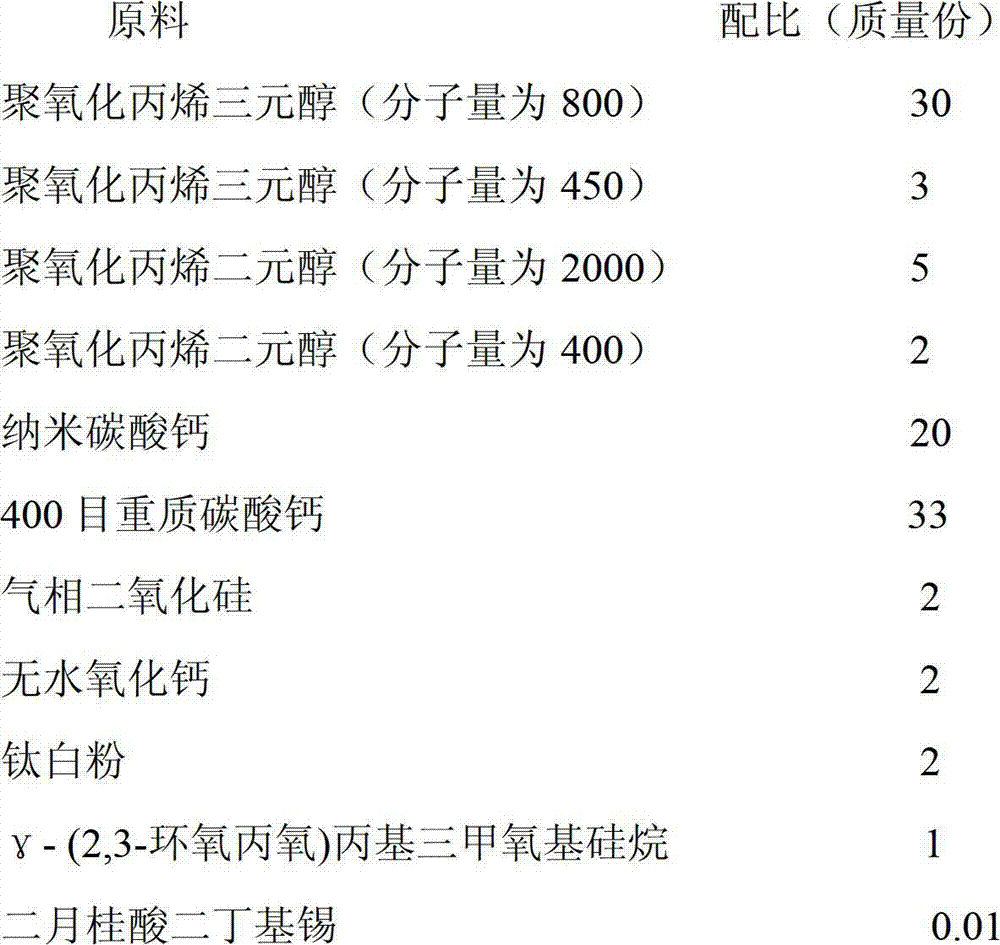

[0049] Get raw materials according to the following ratio:

[0050]

[0051] The molecular weight of 30 mass parts is the polyoxypropylene trihydric alcohol of 800, the molecular weight of 3 mass parts is the polyoxypropylene trihydric alcohol of 450, the molecular weight of 5 mass parts is the polyoxypropylene glycol of 2000, 2 mass parts of Molecular weight is the polyoxypropylene glycol of 400, the nanometer calcium carbonate of 20 mass parts, the 400 order ground calcium carbonate of 33 mass parts, the fumed silic...

Embodiment 2

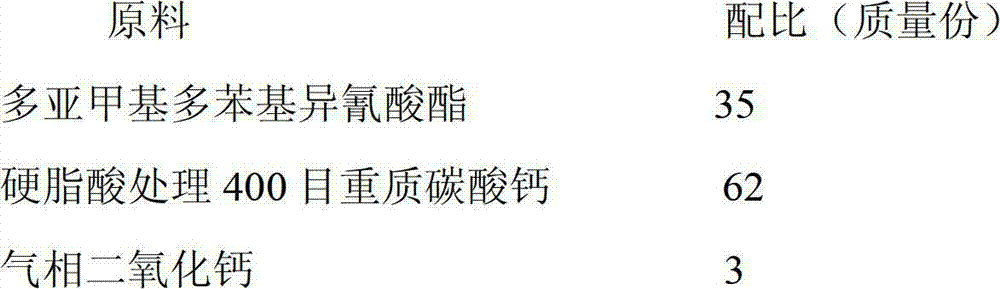

[0058] The second embodiment provides a method for preparing a two-component polyurethane corner glue. The prepared two-component polyurethane corner glue has the characteristics of fast curing speed, excellent bonding performance, and good sealing performance. It is used for heat insulation (broken bridge) corner joints and corner joints of aluminum alloy doors and windows. The preparation method specifically includes:

[0059] Prepare the first component:

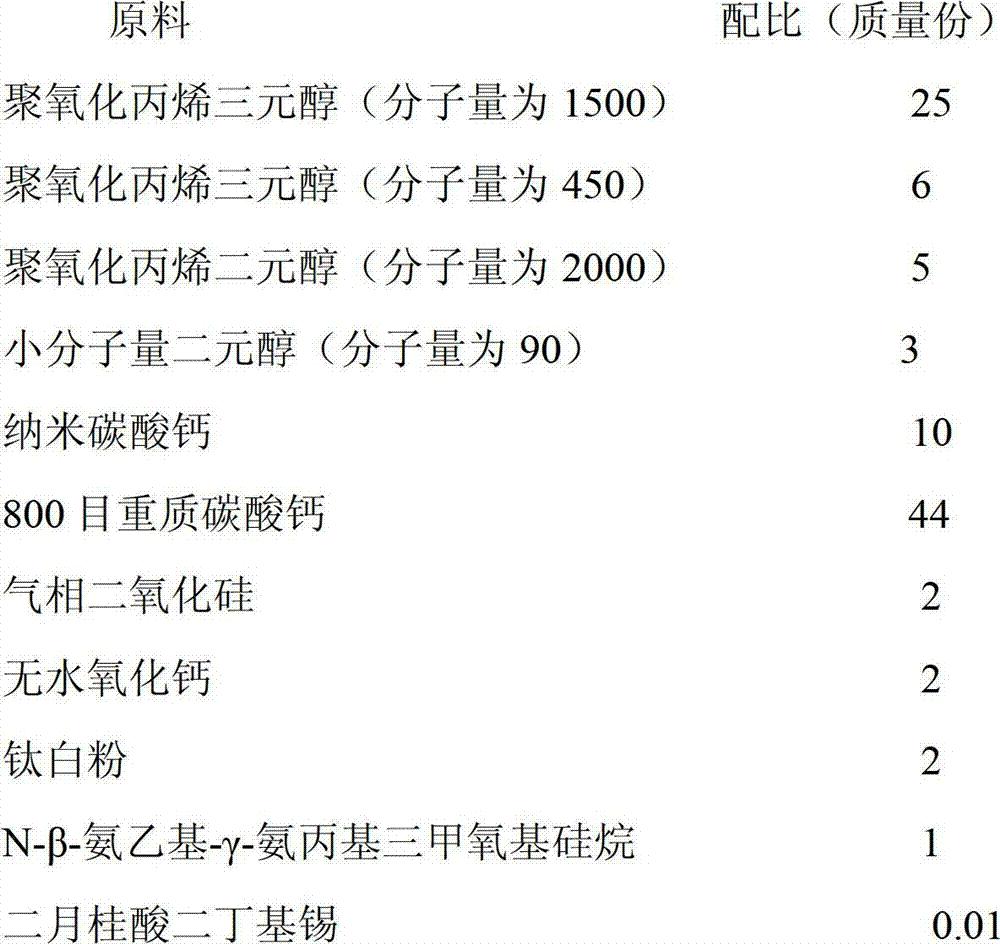

[0060] Get raw materials according to the following ratio:

[0061]

[0062] The molecular weight of 25 mass parts is the polyoxypropylene trihydric alcohol of 1500, the molecular weight of 6 mass parts is the polyoxypropylene trihydric alcohol of 450, the molecular weight of 5 mass parts is the polyoxypropylene glycol of 2000, 3 mass parts of Molecular weight is 90 small molecular glycols, 10 mass parts of nano calcium carbonate, 44 mass parts of 800 mesh heavy calcium carbonate, 2 mass parts of fumed silica, 2 mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com