Method for preparing cyclohexene oxide

A technology of epoxycyclohexane and cyclohexene, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve unfavorable large-scale industrial application, high cost, and catalyst Complicated preparation process and other problems, to achieve the effect of increasing catalyst performance, low cost, and shortening residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029]Example: Preparation of Heterogeneous Supported Composite Oxide Catalyst

[0030] Add 9.70g (55mmol) ammonium paramolybdate tetrahydrate into 50mL deionized water, heat to 100°C under stirring, add 1.5mL acetic acid to adjust the pH to 4.5, add 5mmol NaH successively 2 PO 4 , 5mmol Fe(SO 4 ) 2 , 0.5M H 2 SO 4 10mL. Continue to stir under heating until a small amount of water remains, and after cooling, the target product solid is precipitated, and the product PMo is obtained after filtration and drying. 11 Fe 1 9.00g;

[0031] Using excessive impregnation method: in a 100mL three-neck round bottom flask, add the Ti silicon ratio of 0.12:1 prepared according to the method of the above-mentioned content of the invention. 0.12 -MCM-41 molecular sieve 3.0g, the heteropolyacid salt PMo prepared above 11 Fe 1 Dissolve 0.60 g in 40 mL deionized water and pour it into a round bottom flask with Ti 0.12 -MCM-41 mixed, stirred continuously in an oil bath at 60°C until...

Embodiment 2~4

[0032] Embodiment 2~4: the complex oxide that different roasting temperature makes is catalyzed to prepare epoxycyclohexane

[0033] In three 50mL three-neck round bottom flasks, add the PMo prepared above with a loading capacity of 20%. 11 Fe 1 / Ti 0.12 -MCM-41-400°C / 500°C / 600°C catalyst 0.2g, cyclohexene 1.64g (20mmol), acetonitrile 4.9g (0.12mol), the flask was reacted at a constant temperature in a 60°C oil bath, refluxed for 10 hours, and continuously Stir, and add 2.05mL (20mmol) of 30% hydrogen peroxide at a constant speed with a micro-sampling pump, and the dropwise addition time is half of the reaction time (5h). After the reaction, the catalyst was separated by filtration, and the filtrate was analyzed by gas chromatography for the content of cyclohexene, epoxycyclohexane and the selectivity of epoxycyclohexane. The filtrate is rectified, and the fraction at 130~135°C is collected to obtain the product epoxycyclohexane. The product was qualitatively analyzed by G...

Embodiment example 5~8

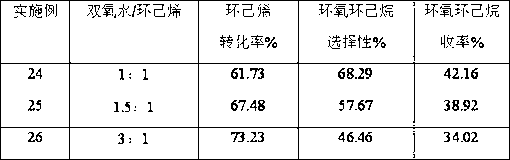

[0036] Implementation Cases 5~8: Catalyzed Preparation of Epoxycyclohexane by Heterogeneous Composite Oxide Catalysts Prepared from Molybdophosphorus Heteropolysalts with Different Molar Ratio of Fe and P

[0037] Use 20% PMo 12-n Fe n / Ti 0.2 -MCM-41-600°C is used as catalyst, other preparation conditions are the same as cases 1~3. The difference is that the heteropoly acid salt PMo 12-n Fe n The molar ratio of Fe and P (namely n) in the case, n=0.5 in case 5, n=1 in case 6, n=2 in case 7, and n=3 in case 8. The catalytic performance of these three catalysts was investigated under the same reaction conditions as in Cases 2-4, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com