Preparation and application of special mildew preventing agent for bamboo wood and bamboo products

A technology of antifungal agents and bamboo products, applied in the fields of application, fungicides, chemicals for biological control, etc., can solve the problems of unsatisfactory antibacterial effect, limited source of raw materials, high production cost, etc., and achieve low production cost and source The effect of convenience and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Activate the C3 strain of Lysobacterium enzymogenes.

[0045] The enzyme-producing lysobacterium ( Lysobacter enzymogenes ) The C3 strain was inoculated in the pre-prepared test tube slant medium, and cultured at 24°C for 52h.

[0046] The formula of the slant medium is peptone: 10g, yeast extract: 5g, sodium chloride: 10g, agar: 20g, tap water: 1L; the pH of the medium is 7.0-7.2, and then sterilized at 121°C for 20min.

[0047] The Lysobacter zymogenes C3 strain comes from the American Type Culture Collection, and the strain number is ATCC29487.

[0048] 2. Preparation of shake flask seed solution

[0049] Pick the activated Lysobacterium enzymogenes C3 strain from the slant in the previous step, transfer it to 4 conical flasks containing 100ml of culture solution, and culture it at 28°C and 230rpm for 40h to prepare the shake flask seed solution. One loop of activated Lysobacterium lysobacterium C3 strain was transferred to each conical flask.

[0050] The fo...

Embodiment 2

[0058] 1. Activate the C3 strain of Lysobacterium enzymogenes.

[0059] Inoculate the Lysobacterium enzymogenes C3 strain stored at -80°C in the pre-prepared test tube slant medium on a sterile workbench, and culture at 30°C for 36 hours.

[0060] The formula of the slant culture medium is the same as in Example 1.

[0061] 2. Preparation of shake flask seed solution

[0062] The activated Lysobacterium enzymogenes C3 strain was picked from the slope, transferred to 7 conical flasks containing 100ml of culture solution, and cultured at 24°C and 230rpm for 48h to prepare shake flask seed solution. One loop of activated Lysobacterium lysobacterium C3 strain was transferred to each conical flask.

[0063] The formulation of the culture solution and the sterilization method are the same as in Example 1.

[0064] 3. Preparation of Lysobacterium enzymogenes C3 antifungal agent

[0065] Using a 10 L fermenter, inject 6L of culture fluid, inoculate 600ml shake flask seed liquid in...

Embodiment 3

[0073] 1. Activate the C3 strain of Lysobacterium enzymogenes.

[0074] Same as Example 1.

[0075] 2. Preparation of shake flask seed solution

[0076] Same as Example 1.

[0077] 3. Preparation of Lysobacterium enzymogenes C3 antifungal agent

[0078] Same as Example 2.

[0079] 4. Antifungal agent heat sterilization treatment

[0080] The preparation process is the same as that of heat treatment example 2, and the prepared antifungal agent is stored at room temperature for 180 days before use.

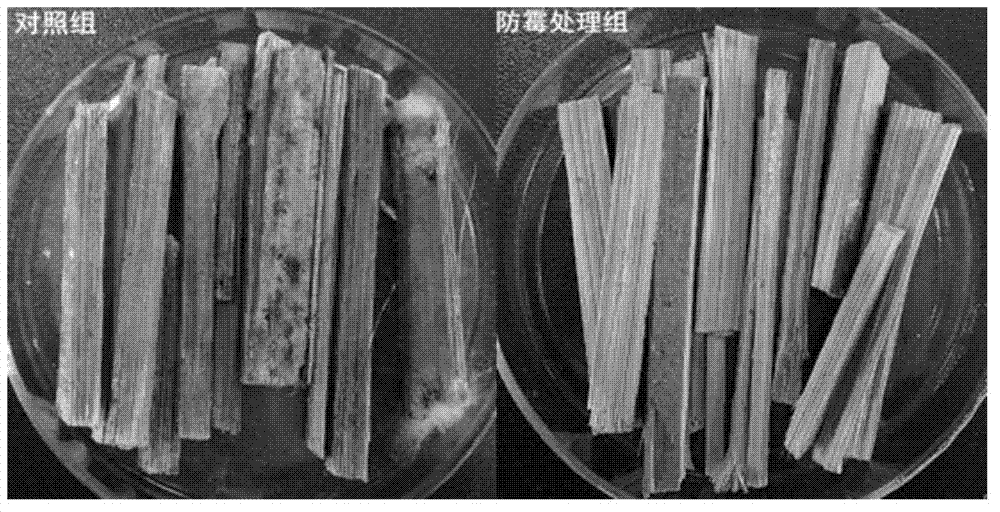

[0081] 5. Anti-mildew treatment of bamboo soaking method

[0082] Cut the fresh bamboo into small pieces of about 7×0.5cm, and divide them into two groups at random. The control group was soaked in sterile water for 4 hours, and the treatment group was soaked in 180-day stored lysobacterium C3 antifungal agent for 4 hours. After soaking, take them out and place them in dry sterile petri dishes, and place them at room temperature. The result is as Figure 5 As shown, the smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com