Moisture-proof and mildew-proof putty suitable for humid environment

A damp environment, anti-mildew technology, applied in the direction of filling slurry, etc., can solve the problems of mold, putty layer falling off due to moisture, etc., to achieve stable performance, prevent moisture and mildew, and good water resistance and anti-mold performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

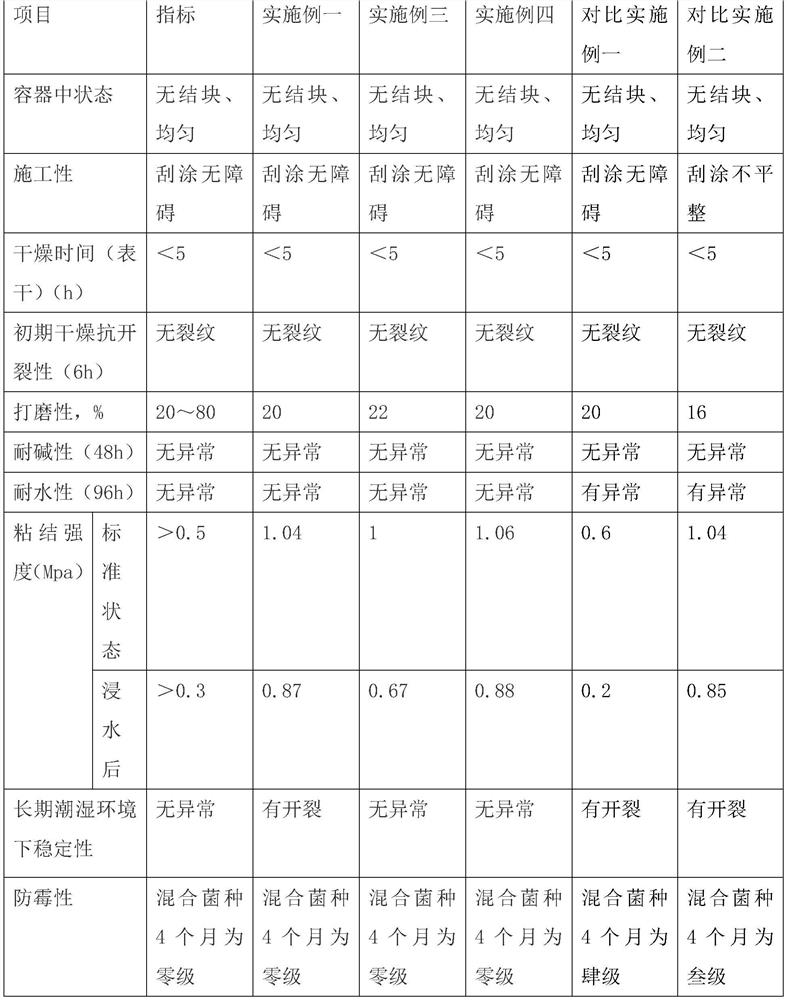

Examples

Embodiment 1

[0014] Embodiment 1: A moisture-proof and mildew-proof putty suitable for humid environments, which is formed by uniformly mixing the following components in parts by weight: 30 parts of heavy calcium, 40 parts of gray calcium, 3 parts of mold-proof materials, hydroxypropyl methyl 5 parts of cellulose, 12 parts of Wacker rubber powder, 3 parts of starch ether, 3 parts of retarder, and 4 parts of lubricant; wherein: the anti-mold material is composed of the following components in parts by weight: 3 parts of nano-titanium dioxide, carbon black 2 parts of zinc oxide, 2 parts of sodium diacetate, 5 parts of superabsorbent resin.

Embodiment 2

[0015] Embodiment 2: A moisture-proof and mildew-proof putty suitable for humid environments, which is formed by uniformly mixing the following components in parts by weight: 25 parts of heavy calcium, 50 parts of gray calcium, 6 parts of mold-proof materials, hydroxypropyl methyl 6 parts of cellulose, 8 parts of Wacker rubber powder, 5 parts of starch ether, 5 parts of retarder, and 8 parts of lubricant; wherein: the anti-mold material is composed of the following components in parts by weight: 2 parts of nano-titanium dioxide, carbon black 4 parts of zinc oxide, 4 parts of sodium diacetate, 8 parts of superabsorbent resin.

Embodiment 3

[0016] Embodiment 3: A moisture-proof and mildew-proof putty suitable for humid environments, which is formed by uniformly mixing the following components in parts by weight: 30 parts of heavy calcium, 40 parts of gray calcium, 8 parts of mold-proof materials, hydroxypropyl methyl 5 parts of cellulose, 7 parts of Wacker rubber powder, 3 parts of starch ether, 3 parts of retarder, and 4 parts of lubricant; wherein: the anti-mold material is composed of the following components in parts by weight: 3 parts of nano-titanium dioxide, carbon black 4 parts of zinc oxide, 4 parts of sodium diacetate, 10 parts of super absorbent resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com