Compound with triphenylamine structure, and organic electroluminescent element

A technology of arylamine compound and triphenylamine, which is applied in the field of compounds with triphenylamine structure and organic electroluminescent devices, and can solve the problems that have never been heard of, and the material of the hole transport layer is not suitable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

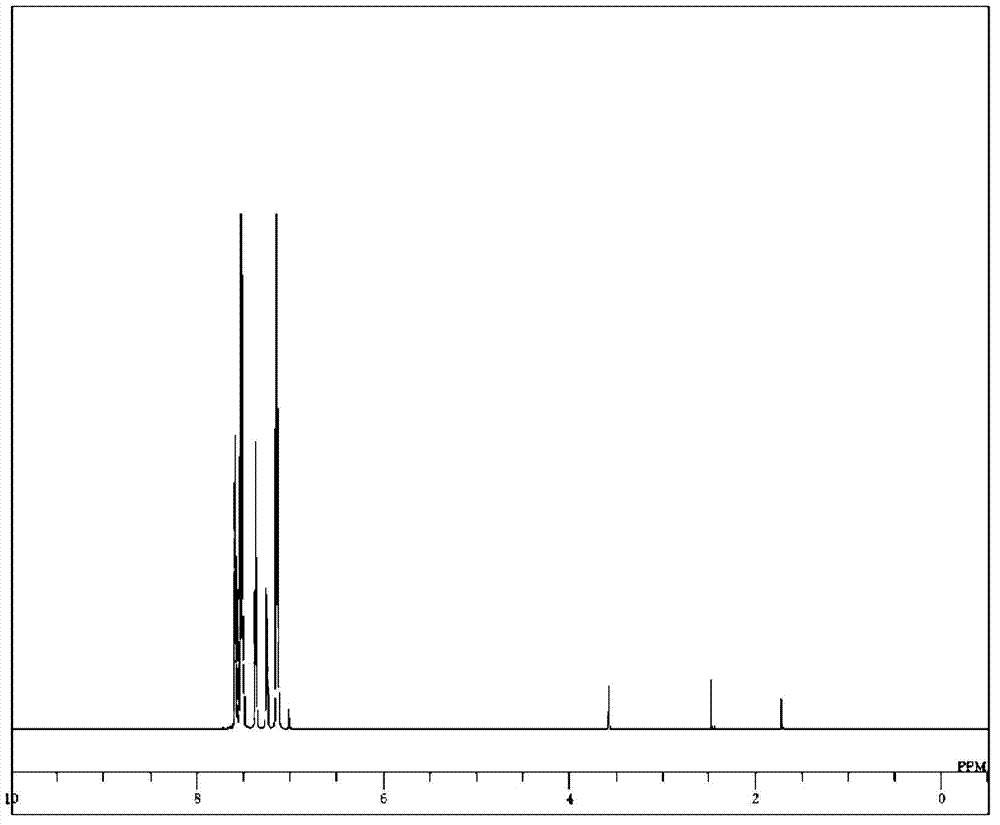

Image

Examples

Embodiment 1

[0222] 5 )-Amino]biphenyl (Compound 5) Synthesis>

[0223] Add 30.00g of aniline-2,3,4,5,6-d5 and 50ml of acetic acid to a nitrogen-substituted reaction vessel, heat to 70°C while stirring, then add 34.7ml of acetic anhydride dropwise, and further heat at 70°C Stirring was continued for 4 hours. After cooling to room temperature, the reaction solution was poured into ice water, and the precipitated crystals were separated by filtration to obtain 48.71 g of light brown crystals. On the other hand, the filtrate was transferred to a separatory funnel, and 1000 ml of toluene was added for extraction operation. The extract was concentrated and dried to obtain 4.05 g of brown crystals. These crystals were combined and dried under reduced pressure to obtain 41.33 g (yield 96.5%) of acetanilide-2,3,4,5,6-d 5 of brown crystals.

[0224] 35.00g of the resulting acetanilide-2,3,4,5,6-d 5 , 48.50 g of 4-bromobiphenyl, 1.32 g of copper powder, 43.14 g of potassium carbonate, 6.53 g of ...

Embodiment 2

[0230] 9 Synthesis of -4-yl)-phenylamino}biphenyl (compound 49)>

[0231] In the nitrogen replaced reaction vessel, add 16.08g of bromobenzene-d 5 , 13.79g (phenyl-d 5 ) boric acid, 20.46g of potassium carbonate, 74ml of water, 160ml of toluene, and 40ml of ethanol, while irradiating ultrasonic waves, nitrogen gas was introduced for 30 minutes. Add 2.28 g of tetrakis(triphenylphosphine)palladium, heat and stir under reflux for 7.5 hours. After allowing to cool to room temperature, a liquid separation operation was performed, and the organic layer was collected, dried with magnesium sulfate, and then concentrated to obtain 22.27 g of a black crude product. The crude product was purified by column chromatography (carrier: silica gel, eluent: n-hexane) to obtain 14.07 g (yield 86%) of white crystals of biphenyl-d10.

[0232] 14.07g of the resulting biphenyl-d 10 , 0.28g of iron(III) chloride, 2.2ml of bromine, and 70ml of chloroform were added to the reaction vessel replaced ...

Embodiment 3

[0238] 4 Synthesis of )-4-yl]amino}biphenyl (compound 18)>

[0239] In a reaction vessel replaced with nitrogen, add 20.0 g (biphenyl-4-yl)-(phenyl-d 5 ) amine and 400ml of DMF were dissolved, and then 4.7g of N-bromosuccinimide was added under ice cooling. While adding 9.4 g of N-bromosuccinimide in two portions, the reaction temperature was raised to room temperature. After stirring for 3 hours, the reaction solution was added dropwise to 2000 ml of water, and the precipitated solid was collected by filtration. 1000 ml of toluene was added to the obtained solid to dissolve it, and after drying with magnesium sulfate, a filtration operation was performed, and the filtrate was concentrated. Add 200ml of n-hexane to the obtained concentrate, carry out dispersion washing, dry under reduced pressure overnight, obtain 23.4g (yield 89.0%) (biphenyl-4-yl)-4-bromo(phenyl-2,3, 5,6-d 4 ) Red-black solid of amine.

[0240] 23.0 g of the resulting (biphenyl-4-yl)-4-bromo(phenyl-2,3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com