Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, transportation fuel cell technology, etc., can solve the problems of FC degradation suppression that have not been studied, so as to suppress the generation of surplus power or insufficient power and prevent deterioration , The effect of reducing the amount of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1. Description of the overall composition

[0047] [1-1. Overall composition]

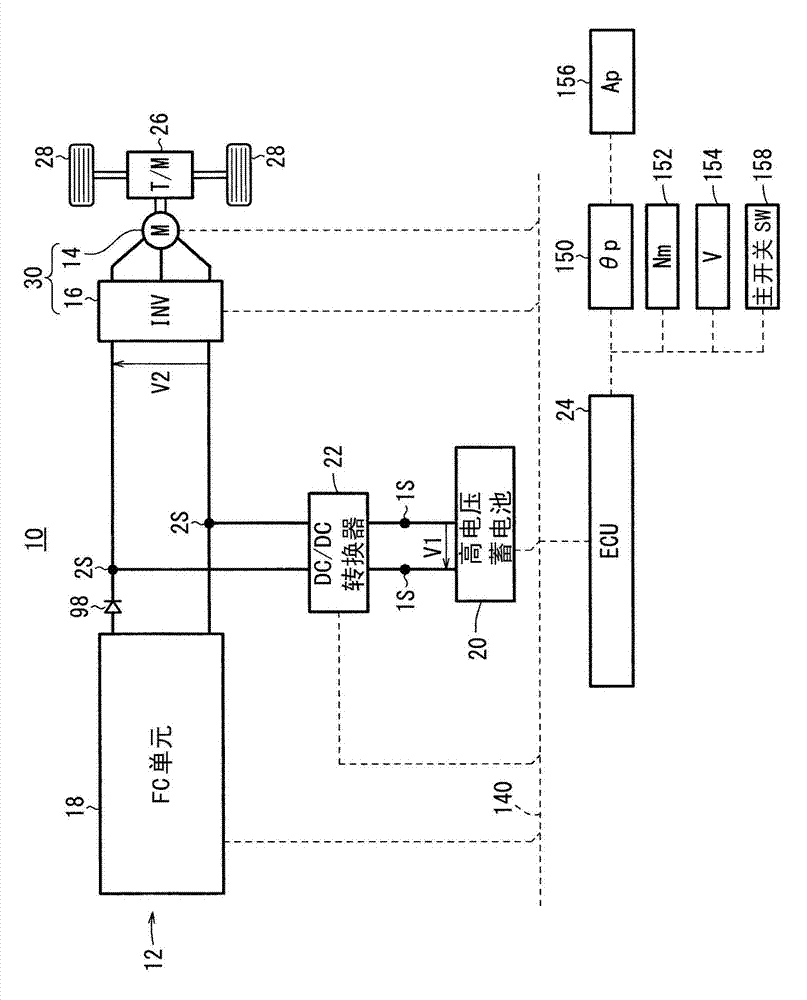

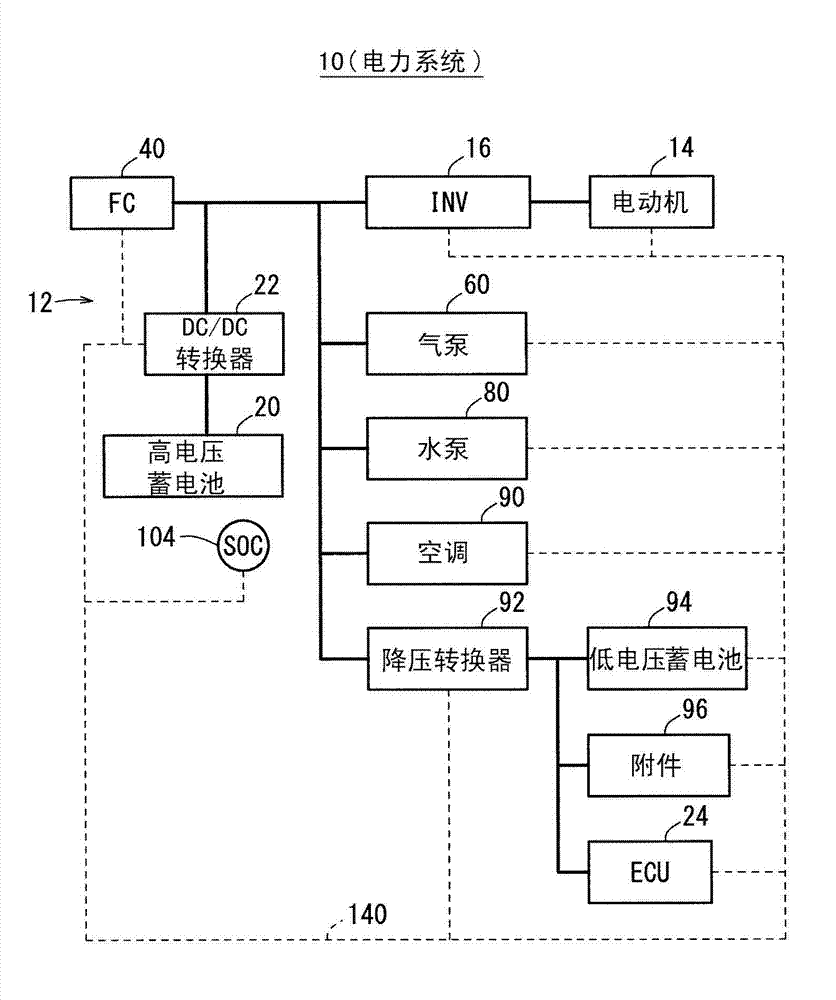

[0048] figure 1 It is a schematic overall configuration diagram of a fuel cell vehicle 10 (hereinafter referred to as "FC vehicle 10") equipped with a fuel cell system 12 (hereinafter referred to as "FC system 12") according to an embodiment of the present invention. figure 2 is a block diagram of the power system of the FC vehicle 10 . Such as figure 1 and figure 2 As shown, the FC vehicle 10 includes, in addition to the FC system 12 , an electric motor 14 and an inverter 16 for traveling.

[0049] The FC system 12 has a fuel cell unit 18 (hereinafter referred to as “FC unit 18 ”), a high-voltage battery 20 (hereinafter also referred to as “battery 20 ”) (power storage device), and a DC / DC converter (converter) 22 . The electronic control unit 24 (hereinafter referred to as "ECU24").

[0050] [1-2. Drive system]

[0051]The electric motor 14 generates driving force based on elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com