Preparation method for flexible electrode material for super capacitor

A technology of supercapacitors and flexible electrodes, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of lack of stretchability, complicated manufacturing process, and limited practical application, and achieve the effect of good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

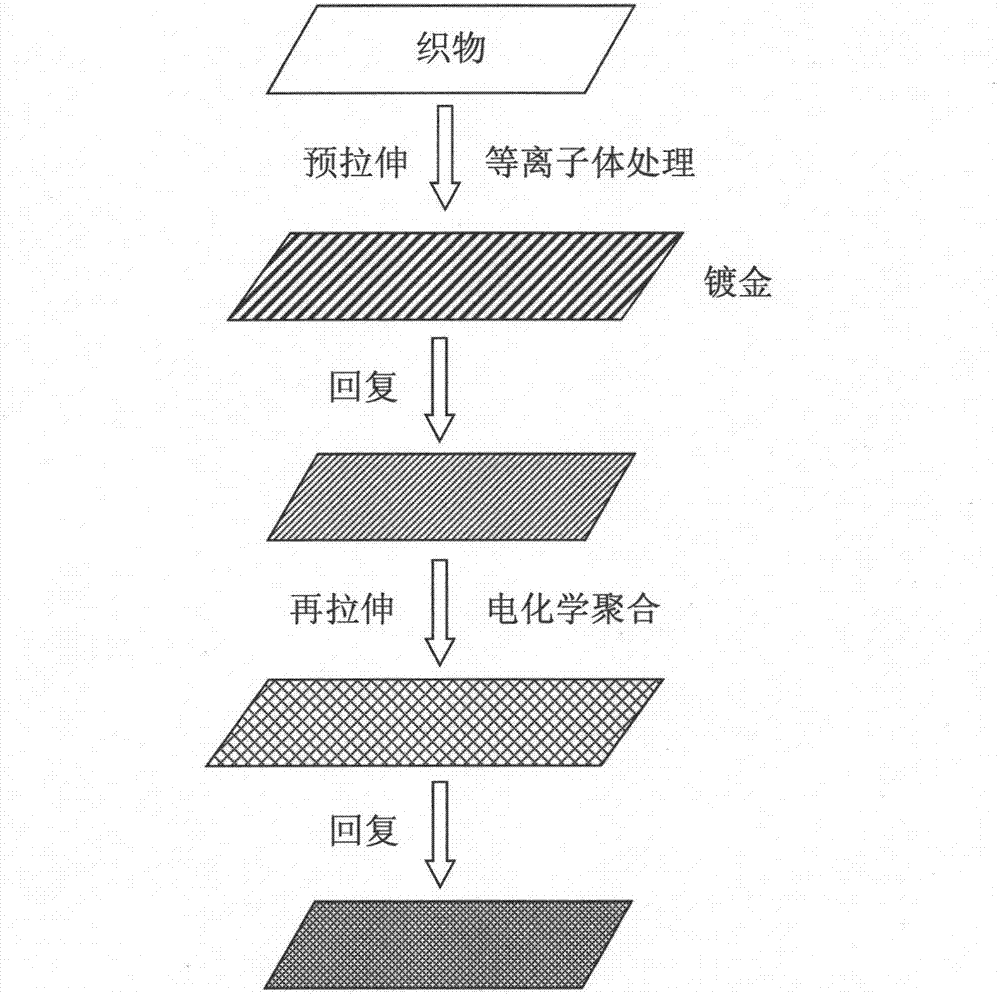

[0023] figure 1 A flow chart of a method for preparing a flexible electrode material for a supercapacitor provided by the invention, the method for preparing a flexible electrode material for a supercapacitor is divided into the following 2 steps:

[0024] Step 1: Preparation of gold-coated fabric: After the fabric is thoroughly washed with sodium hydroxide solution and detergent, it is stretched and fixed; after air plasma treatment for 30 seconds, the surface of the fabric is plated with gold by magnetron sputtering, and the thickness of the gold plating is about It is 300nm; After the end, the fabric is relaxed to obtain a gold-coated fabric;

[0025] Step 2: Preparation of polypyrrole composite fabric: Add dopant p-toluenesulfonic acid to acetonitrile solution to obtain 0.1mol / L A solution, add pyrrole monomer to A solution to make its concentration 0.1mol / L, and obtain B solution; add B solution in the electrolytic cell equipped with three electrodes, and the reference e...

Embodiment 2

[0027] figure 1 A flow chart of a method for preparing a flexible electrode material for a supercapacitor provided by the invention, the method for preparing a flexible electrode material for a supercapacitor is divided into the following 2 steps:

[0028] Step 1: Preparation of gold-coated fabric: After the fabric is thoroughly washed with sodium hydroxide solution and detergent, it is stretched by 50% and fixed; after air plasma treatment for 30s, the surface of the fabric is plated with gold by magnetron sputtering, and the thickness of the gold plated About 200nm; relax the fabric after the end to get a gold-coated fabric;

[0029] Step 2: Preparation of polypyrrole composite fabric: Add dopant p-toluenesulfonic acid to acetonitrile solution to obtain 0.1mol / L A solution, add pyrrole monomer to A solution to make its concentration 0.1mol / L, and obtain Solution B; add solution B to an electrolytic cell equipped with three electrodes, the reference electrode in the three el...

Embodiment 3

[0031] figure 1 A flow chart of a method for preparing a flexible electrode material for a supercapacitor provided by the invention, the method for preparing a flexible electrode material for a supercapacitor is divided into the following 2 steps:

[0032] Step 1: Preparation of gold-coated fabric: After the fabric is thoroughly washed with sodium hydroxide solution and detergent, it is stretched by 50% and fixed; after air plasma treatment for 30s, the surface of the fabric is plated with gold by magnetron sputtering, and the thickness of the gold plated About 200nm; relax the fabric after the end to get a gold-coated fabric;

[0033] Step 2: Preparation of polypyrrole composite fabric: Add dopant p-toluenesulfonic acid to acetonitrile solution to obtain 0.1mol / L A solution, add pyrrole monomer to A solution to make its concentration 0.1mol / L, and obtain Solution B; add solution B to an electrolytic cell equipped with three electrodes, the reference electrode in the three el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com