Apparatus and method for producing road petroleum asphalt from ultra heavy oil

A technology for road petroleum asphalt and super-heavy oil, which is applied in the direction of refining and cracking process treatment only in multi-stage series, can solve the problem of inability to produce heavy-cross asphalt, etc., and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

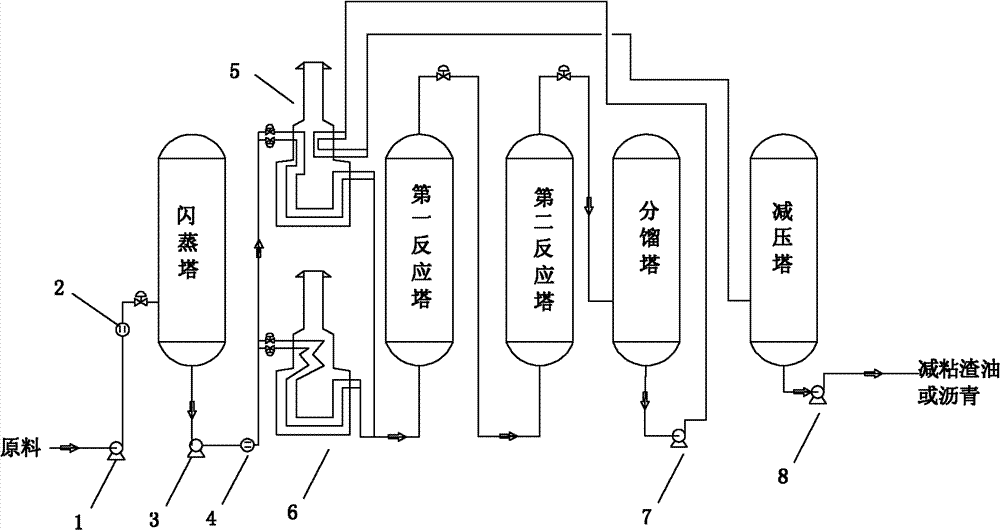

[0021] see figure 1 , the embodiment of the present invention provides a device for producing road asphalt from super heavy oil, including a raw material pump 1, a first heat exchanger 2, a flash tower, a flash bottom pump 3, a second heat exchanger 4, a heating furnace, Reaction tower, fractionation tower, tower bottom pump 7, vacuum tower and residual oil pump 8. One end of the first heat exchanger 2 is connected to the raw material pump 1, the other end is connected to the flash tower, the bottom of the flash tower is connected to the flash bottom pump 3, and the flash bottom pump 3 is connected to the second heat exchanger 4 , the second heat exchanger 4 is connected with the heating furnace, the heating furnace is connected with the bottom of the reaction tower, the top of the reaction tower is connected with the fractionation tower, and the bottom of the fractionation tower is connected with the bottom pump 7, The tower bottom pump 7 is connected to the heating furnace,...

Embodiment 2

[0027] The embodiment of the present invention provides a method for producing road asphalt from super heavy oil, the device used in the method is the device provided in embodiment 1, and the method mainly includes the following steps:

[0028] see figure 1 , the raw material used in this embodiment is Venezuelan super heavy oil (Liaohe super heavy oil), and the Venezuelan super heavy oil with a temperature of about 85-90 ° C is sent to the first heat exchanger 2 for heat exchange after the raw material pump 1 boosts the pressure. After heating to a temperature of 187°C, it is sent into the flash tower from below the flash tower. The oil and gas at the top of the flash tower is condensed by the flash top oil-gas air cooler (not shown in the figure), cooled to 40°C by the flash top oil-gas aftercooler (not shown in the figure), and then enters the flash top oil-water separation tank (not shown in the figure) ) to carry out gas-liquid separation, and the flash bottom oil is obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com