A pour point depressant and viscosity depressant for high pour point thick oil and preparation method thereof

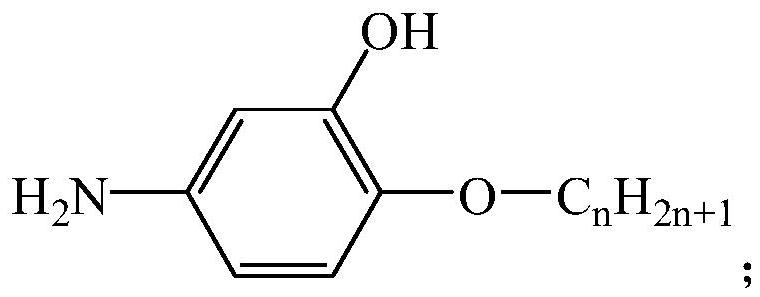

A technology of high pour point heavy oil and pour point depressant, applied in the field of pour point depressant and viscosity reducer, which can solve the problems of high wax content and inability to reduce viscosity of high pour point heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

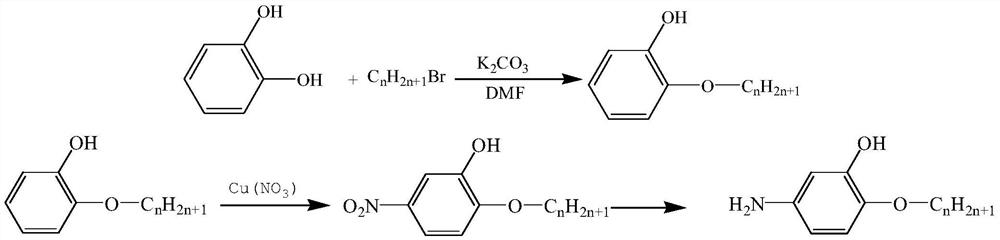

Method used

Image

Examples

Embodiment 1

[0027] Example 1: pour point and viscosity reducer A 1 preparation of

[0028] (1) Add 1mol catechol and 550g solvent N,N-dimethylformamide into a three-necked flask, heat up to 45°C, stir at 200rpm, and stir for 20min; add 110g of potassium carbonate into the three-necked flask, Raise the temperature to 78°C; then add 1.0mol dodecyl bromide while stirring, the stirring speed is 500rpm, after reacting for 10h, cool to room temperature, pour the reaction liquid into ice water at 0°C, and filter the solid precipitate in the reaction liquid to obtain The crude product was dried in an oven at 80°C for 24 hours to obtain the intermediate o-hydroxyphenyl ether;

[0029] (2) Add the above-mentioned intermediate o-hydroxyphenyl ether into a round-bottomed flask, add 22g of copper nitrate and 55g of acetic acid, the temperature is 30°C, and the stirring speed is 300rpm. After completely dissolving, the reaction temperature is raised to 50°C and stirred The speed is 250rpm, and the re...

Embodiment 2

[0033] Example 2: pour point and viscosity reducer A 2 preparation of

[0034] (1) Add 1mol catechol and 700g solvent N,N-dimethylformamide into a three-necked flask, raise the temperature to 30°C, stir at 250rpm, and stir for 40min; add 135g potassium carbonate into the three-necked flask, Raise the temperature to 76°C; then add 1.2mol tetradecyl bromide while stirring, the stirring speed is 520rpm, after reacting for 12h, cool to room temperature, pour the reaction liquid into ice water at 0°C, and filter the solid precipitate in the reaction liquid to obtain The crude product was dried in an oven at 83°C for 30 hours to obtain the intermediate o-hydroxyphenyl ether;

[0035](2) Add the above-mentioned intermediate o-hydroxyphenyl ether into a round bottom flask, add 32g of copper nitrate and 88g of acetic acid, the temperature is 32°C, and the stirring speed is 350rpm. After completely dissolving, the reaction temperature is raised to 55°C and stirred The speed is 300rpm,...

Embodiment 3

[0039] Example 3: pour point and viscosity reducer A 3 preparation of

[0040] (1) Add 1mol catechol and 950g solvent N,N-dimethylformamide into a three-necked flask, raise the temperature to 38°C, stir at a speed of 300rpm, and stir for 30min; add 150g of potassium carbonate into the three-necked flask, Raise the temperature to 75°C; then add 1.3mol hexadecyl bromide while stirring, the stirring speed is 550rpm, after reacting for 13h, cool to room temperature, pour the reaction liquid into ice water at 0°C, and filter the solid precipitate in the reaction liquid to obtain The crude product was dried in an oven at 86°C for 32 hours to obtain the intermediate o-hydroxyphenyl ether;

[0041] (2) Add the above-mentioned intermediate o-hydroxyphenyl ether into a round bottom flask, add 45g of copper nitrate and 60g of acetic acid, the temperature is 33°C, and the stirring speed is 380rpm. After completely dissolving, the reaction temperature is raised to 60°C and stirred The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com