Oil-soluble viscosity reducer for super heavy oil and preparation method of oil-soluble viscosity reducer

An oil-soluble viscosity reducer and viscosity reducer technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carbamic acid derivatives, etc., can solve the problems of large fuel and power consumption, and achieve low cost and salt tolerance Good performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

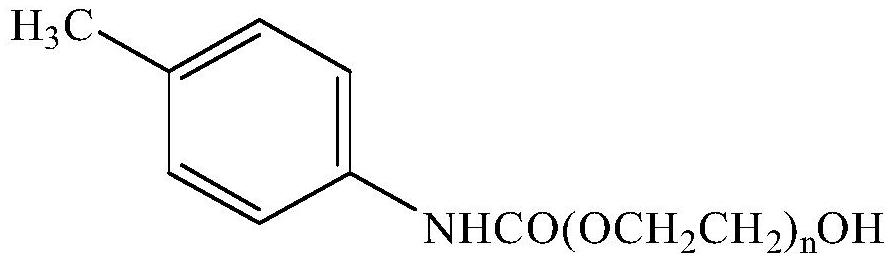

[0055] According to a more specific preferred embodiment, the preparation method of the viscosity reducer specifically includes the following steps:

[0056] (1) Add p-toluene isocyanate into the three-necked flask, then add the solvent, pass nitrogen gas for 3-10 minutes, then heat it in a water bath to 25-40°C, keep the temperature for 10-30 minutes, and slowly add polyethylene glycol dropwise with a constant pressure dropping funnel. Glycol, the dropping rate is 2-5 drops / min, after the dropping is completed, turn on the stirrer, the stirring rate is 500-800rpm, the solution changes from colorless to light yellow, after constant temperature reaction for 1-3h, stop heating, and get mixed liquid;

[0057] (2) Extract the above mixed solution with saturated saline and chloroform mixed solution for 3-5 times, combine the chloroform solution, add magnesium sulfate, dry for 10-20h, filter and distill off the solvent to obtain the final product which is the main ingredient of the ...

Embodiment 1

[0071] Embodiment 1 Viscosity reducer main agent C 1 preparation

[0072] (1) Add 1 mol of p-toluene isocyanate into a three-necked flask, then add 1331.5 g of chloroform, pass nitrogen gas for 3 minutes, then heat in a water bath to 25 ° C, keep the temperature for 10 minutes, and slowly add 1.0 mol of poly Ethylene glycol (n=40~50), the rate of addition is 2 drops / min, after the dropwise addition is completed, the stirrer is turned on, the stirring rate is 500rpm, the solution changes from colorless to light yellow, after constant temperature reaction for 1h, stop heating, get mixed solution;

[0073] (2) The above-mentioned mixed solution was extracted 4 times with saturated saline and chloroform mixed solution, the mass ratio of saturated saline and chloroform was 1:3, and the total single-time dosage was 66.88g. The chloroform solution was combined, and 6.66g of magnesium sulfate was added. Dry for 10 hours, filter and distill off the solvent under reduced pressure to o...

Embodiment 2

[0074] Embodiment 2 Viscosity reducer main agent C 2 preparation

[0075] (1) Add 1 mol of p-toluene isocyanate into a three-necked flask, followed by adding 1597.8 g of dichloromethane, blowing in nitrogen for 5 minutes, then heating in a water bath to 30°C, and after constant temperature for 22 minutes, slowly add 1.2 mol of poly Ethylene glycol (n=10~20), the rate of addition is 3 drops / min, after the dropwise addition is completed, the stirrer is turned on, the stirring rate is 650rpm, the solution changes from colorless to light yellow, after constant temperature reaction for 3h, stop heating, get mixed solution;

[0076] (2) The above-mentioned mixed solution is extracted 3 times with saturated saline and chloroform mixed solution, the mass ratio of saturated saline and chloroform is 1:3, and the single total dosage is 159.78g, the chloroform solution is combined, and 10.65g of magnesium sulfate is added, Dry for 16 hours, filter and distill off the solvent under norma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com