Plastic and application thereof on case wheel bearing

A bearing and luggage technology, applied in the rigid bracket, bearing, application and other directions of bearing components, can solve the problem that the load part cannot be replaced by plastic, and achieve a wide market application prospect, excellent performance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0028] 1. Preparation of plastic

[0029] After uniformly mixing 80-90 parts by weight of POM and 10-20 parts by weight of PU, it is made into powder, pellets or other forms according to the conventional plastic processing technology.

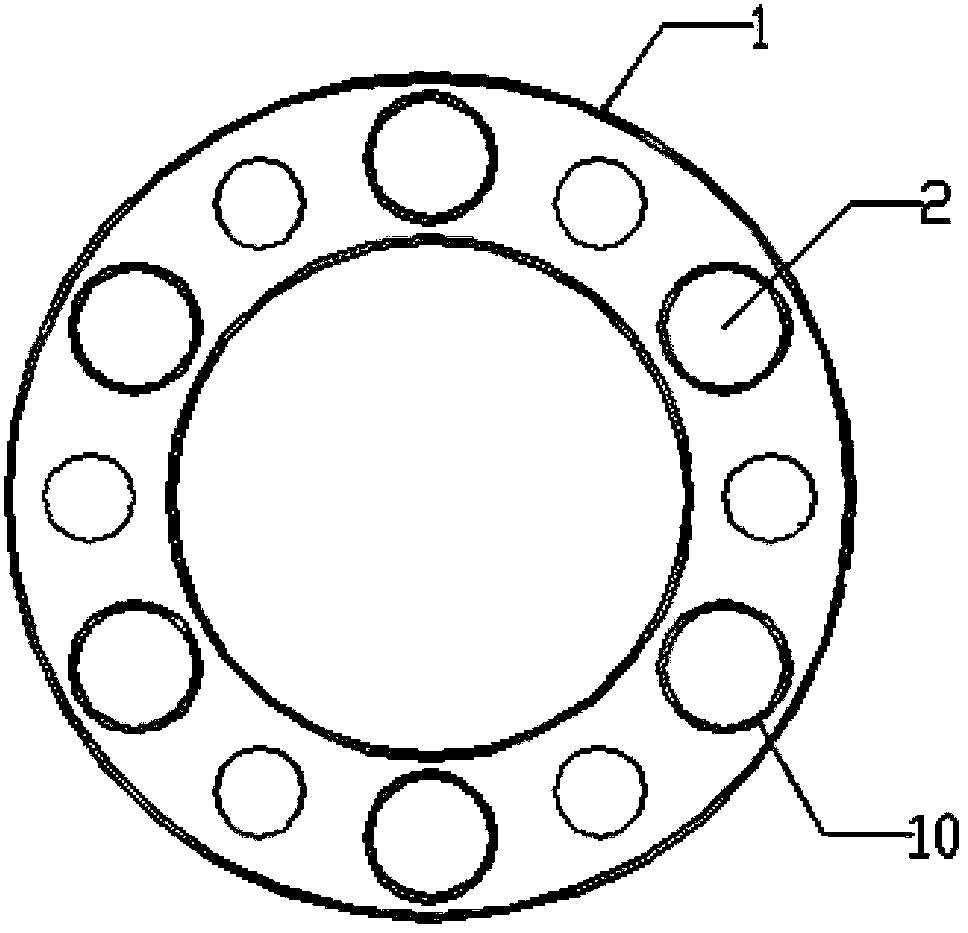

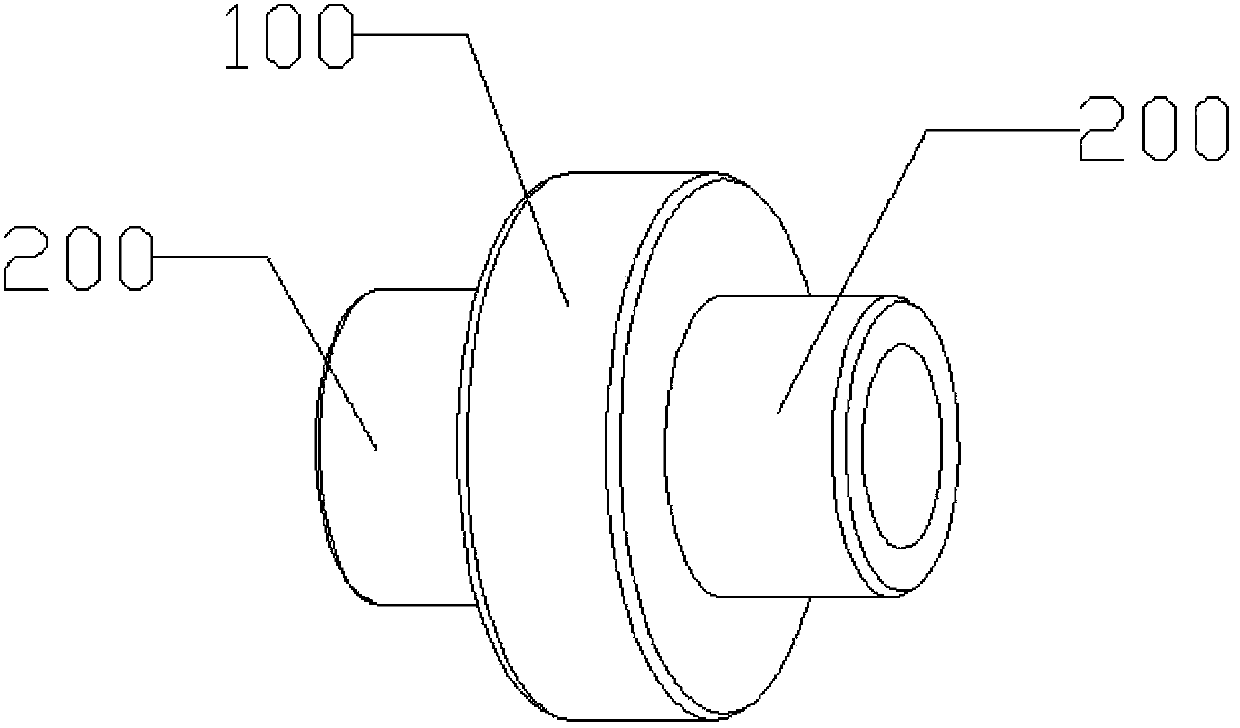

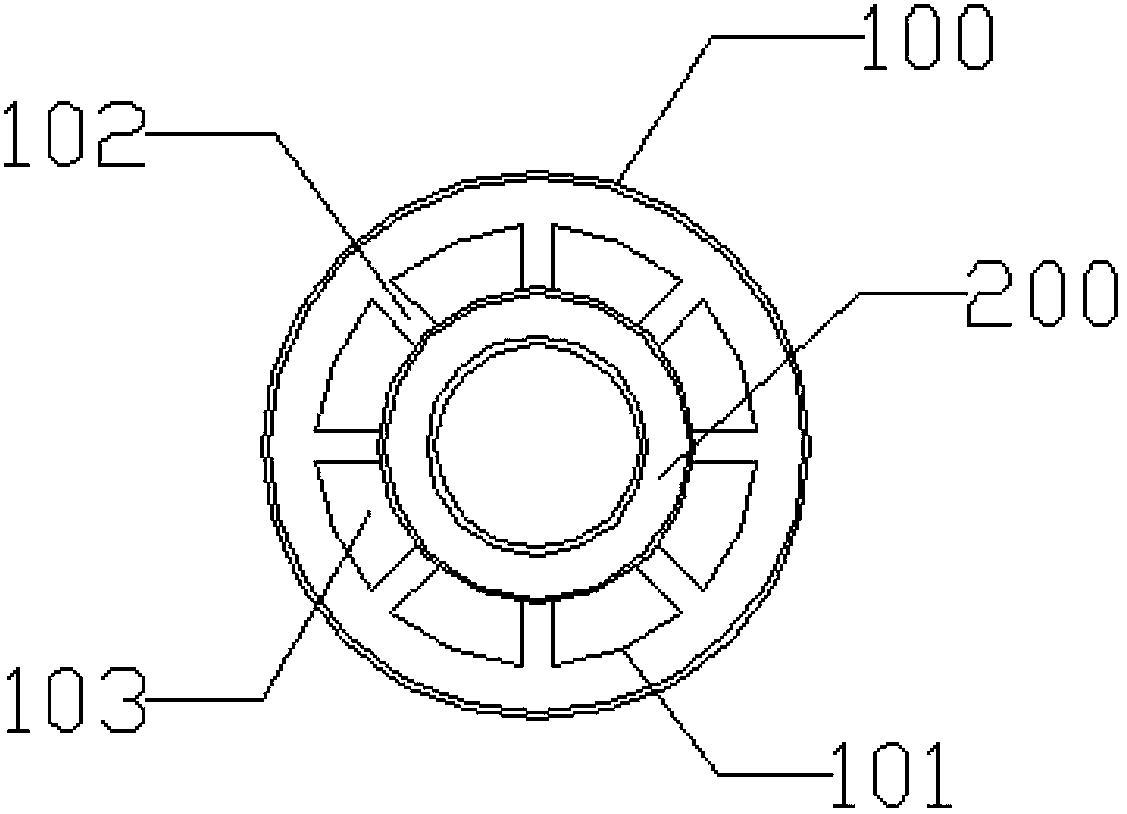

[0030] 2. Making luggage wheel bearings

[0031] The plastic prepared above is molded into various parts of the luggage wheel bearing by using a conventional plastic molding process, and then assembled to obtain the luggage wheel bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com