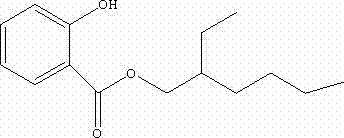

Preparation method of isooctyl salicylate

A technology of isooctyl salicylate and methyl salicylate, which is applied in the field of compound preparation, can solve problems such as high reaction temperature and limited economic benefits, and achieve the effects of high purity, improved economic benefits, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method of isooctyl salicylate of the present invention comprises the following steps:

[0021] In the first step, add isooctyl alcohol solution with a purity of 70% to 99.9% to the methyl salicylate solution with a purity of 70% to 99.9%, and methyl salicylate and isooctyl in the methyl salicylate solution The molar ratio of isooctyl alcohol in the alcohol solution is 1:1-1:3, and the mixture is stirred for 1-3 hours to form a uniformly mixed raw material solution.

[0022] As preferably, in the first step, the molar ratio of the methyl salicylate in the methyl salicylate solution to the isooctyl alcohol in the isooctyl alcohol solution is 1:2.

[0023] In the second step, a solid inorganic base catalyst is added to the raw material solution prepared in the first step, and the mass of the inorganic base catalyst is 0.2%-1.0% of the mass of the raw material solution to form a reaction solution.

[0024] In the second step, the inorganic base cataly...

Embodiment 1

[0031] Add 20 mL of 99.9% pure methyl salicylate solution and 40 mL of 99.9% pure isooctyl alcohol solution into a 150 mL three-necked bottle, stir for 1 hour, and form a uniformly mixed raw material solution after stirring. Add 0.3 g of NaOH to the raw material solution to form a reaction solution; and install a distillation head, a condenser tube, a tail joint tube and a receiving bottle on the three-necked flask respectively. Heat the reaction solution to 150°C, stir and react for 10 hours, recover the methanol in the receiving bottle, cool the three-necked flask to 80°C, wash the reaction solution twice with 100°C hot water, separate and extract the organic phase. with anhydrous Na 2 SO 4 Dry the organic phase and remove the Na in the organic phase after standing for 8 hours 2 SO 4 . Carry out oil pump decompression distillation: first use the oil pump to remove the foreboiler isooctyl alcohol in the organic phase, then heat the container containing the organic phase t...

Embodiment 2

[0038] Add 40 mL of methyl salicylate solution with a purity of 70% and 80 mL of iso-octanol solution with a purity of 85% into a 250 mL three-necked bottle, stir for 3 hours, and form a uniformly mixed raw material solution after stirring. Add 0.6 g of NaOH to the raw material solution to form a reaction solution; and install a distillation head, a condenser tube, a tail joint tube and a receiving bottle on the three-necked flask. Heat the reaction solution to 100°C, stir and react for 4 hours, recover the methanol in the receiving bottle, cool the three-necked flask to 20°C, wash the reaction solution three times with hot water at 50°C, separate and extract the organic phase. with anhydrous Na 2 SO 4 Dry the organic phase and remove the Na in the organic phase after standing for 12 hours 2 SO 4 . Carry out oil pump decompression distillation: first use the oil pump to remove the foreboiler isooctyl alcohol in the organic phase, then heat the container containing the orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com