Lead-free electrostrictive ceramic material and preparation method thereof

A kind of ceramic material and stretching technology, which is applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of lead-based electrostrictive ceramics pollution and other problems, achieve excellent electrostrictive performance, simple production process, and good temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

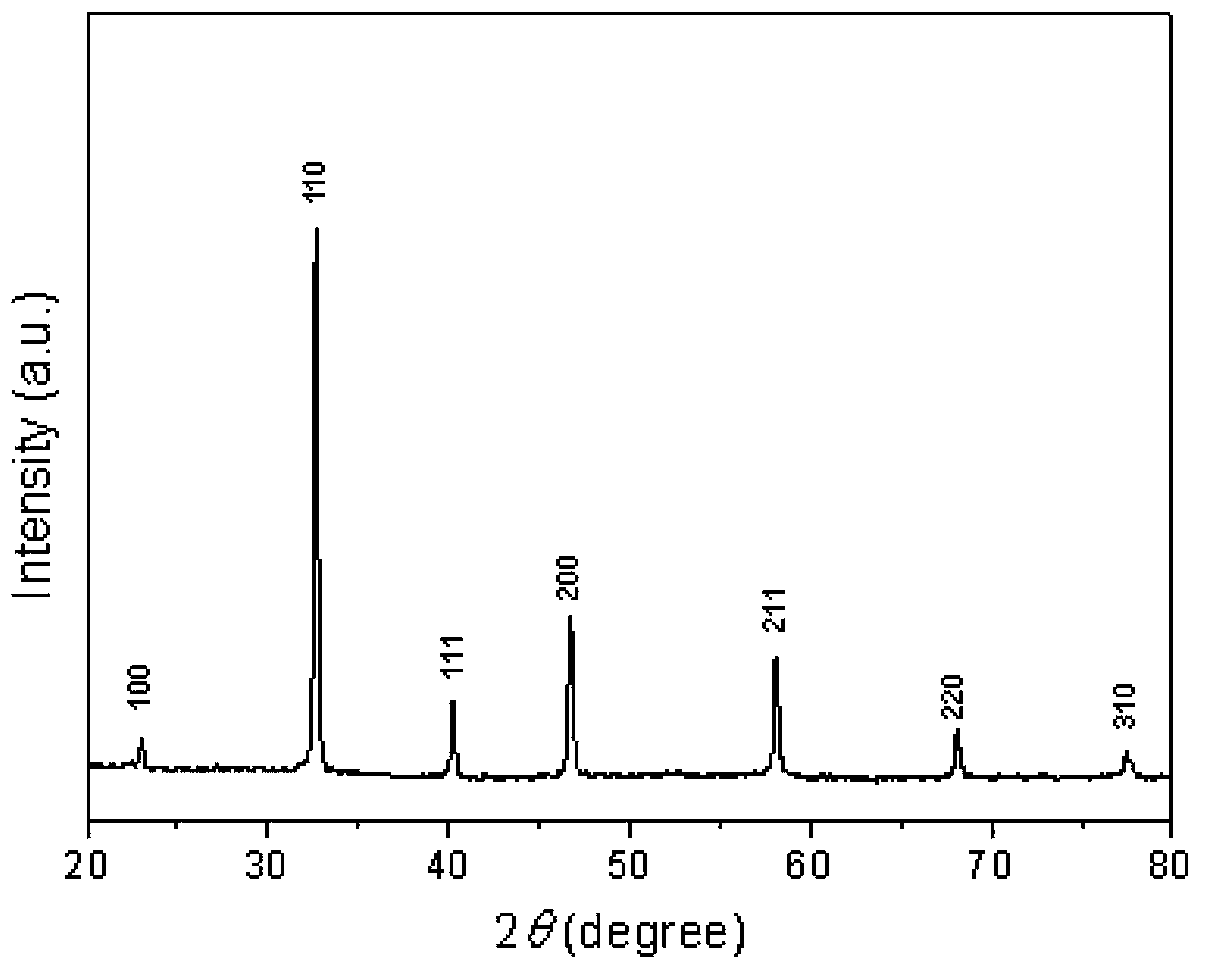

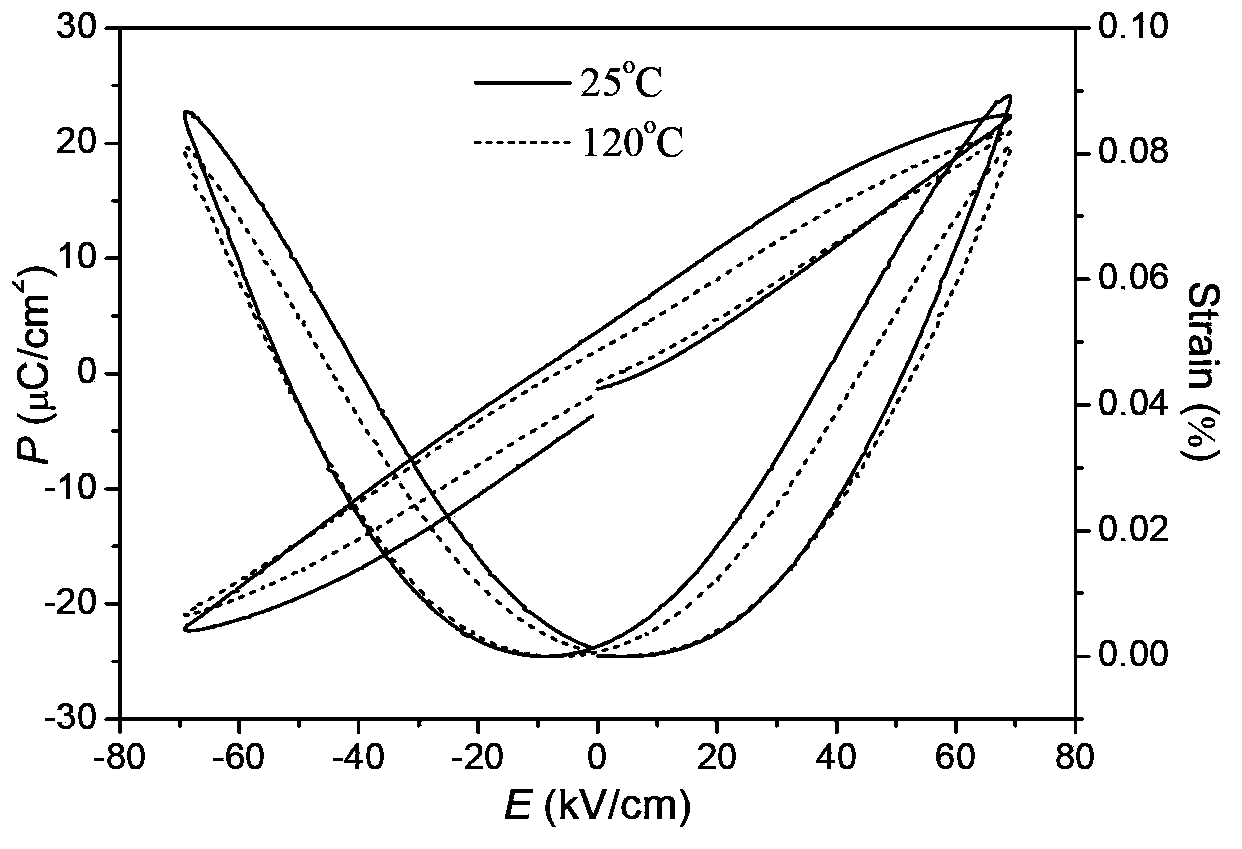

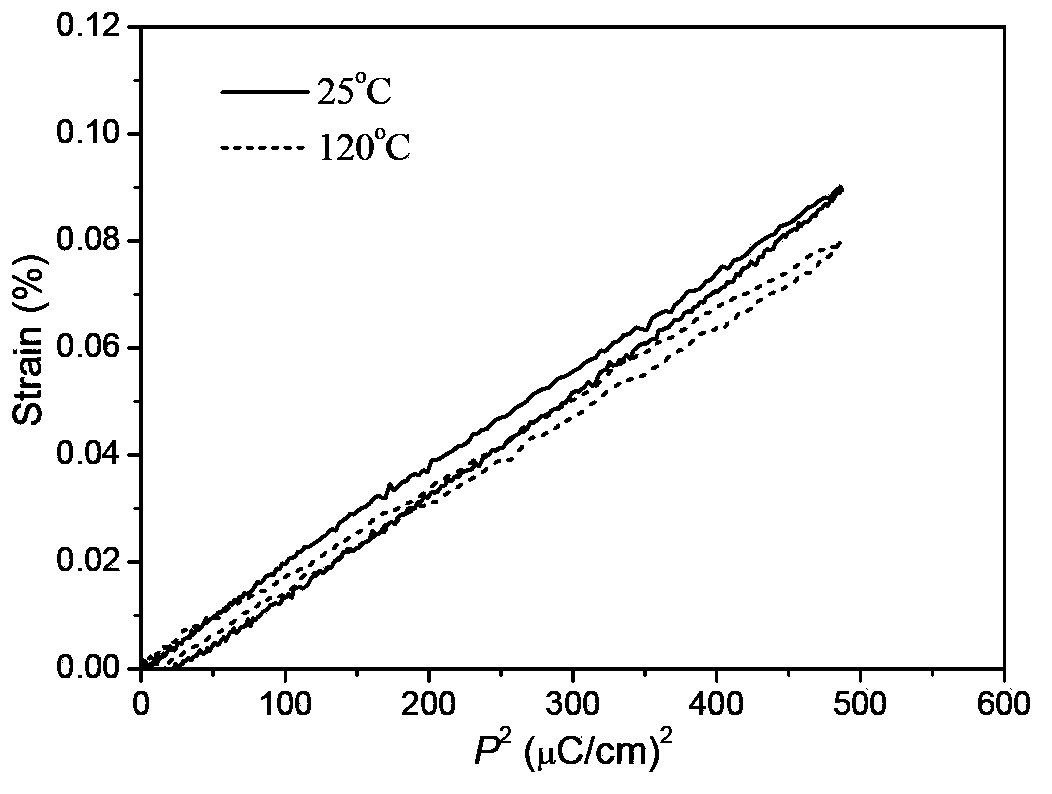

[0043] Take Na 2 CO 3 、K 2 CO 3 、 Bi 2 o 3 、TiO 2 and Nb 2 o 5 (analytical pure) as raw material, according to (1-y) [(1-x) (Bi 0.5 Na 0.5 )TiO 3 -x(Bi 0.5 K 0.5 )TiO 3 ]-y(K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio (molar ratio) of K, Na, Bi, Ti and Nb in (x=0, 0.10≤y≤0.30) Weigh the raw materials, use absolute ethanol as the medium and use ZrO 2 The balls were milled in a ball mill jar for 24 hours, dried and ground, pressed and placed in a closed Al 2 o 3 In the crucible, it was pre-fired at 850°C for 4 hours, and then the pre-fired powder was placed in a ball mill jar for ball milling for 24 hours. After drying, add 8% PVA for granulation, then press molding at 50MPa to obtain a disc with a diameter of 10mm and a thickness of 1mm, deglue at 550°C, and finally sinter at 1150°C for 2 hours to form a ceramic composite with the above formula.

[0044] The ceramic disc is ground into a thin slice with a thickness of 0.5 mm by fine sand, and Ag electrodes ar...

Embodiment 2

[0052] Take Na 2 CO 3 、K 2 CO 3 、 Bi 2 o 3 、TiO 2 and Nb 2 o 5 (analytical pure) as raw material, according to (1-y) [(1-x) (Bi 0.5 Na 0.5 )TiO 3 -x(Bi 0.5 K 0.5 )TiO 3 ]-y(K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio (molar ratio) of K, Na, Bi, Ti and Nb in (x=0.20, 0.10≤y≤0.20) Weigh the raw materials, use absolute ethanol as the medium and use ZrO2 The balls were milled in a ball mill jar for 20 hours, dried, pressed and placed in a closed Al 2 o 3 In the crucible, it was pre-fired at 800°C for 6 hours, and then the pre-fired powder was put back into a ball mill jar for ball milling for 24 hours. After drying, add 10% PVA as a binder for granulation, and then press molding at 100MPa to obtain a disc with a diameter of 15mm and a thickness of 0.8mm, deglue at 500°C, and finally sinter at 1120°C for 8 hours to form a ceramic composite with the above formula things.

[0053] The ceramic disc was polished with fine sand, coated with silver paste on both surfa...

Embodiment 3

[0061] Take Na 2 CO 3 、K 2 CO 3 、 Bi 2 o 3 、TiO 2 and Nb 2 o 5 (analytical pure) as raw material, according to (1-y) [(1-x) (Bi 0.5 Na 0.5 )TiO 3 -x(Bi 0.5 K 0.5 )TiO 3 ]-y(K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio (molar ratio) of K, Na, Bi, Ti and Nb in (x=0.40, 0.10≤y≤0.30) Weigh the raw materials, use absolute ethanol as the medium, and use ZrO 2 The balls were milled in a ball mill jar for 24 hours, dried and ground, pressed and placed in a closed Al 2 o 3 In a crucible, it was pre-fired at 900°C for 2 hours, and then the pre-fired powder was put back into a ball mill jar for ball milling for 24 hours. After drying, add 8% PVA as a binder for granulation, and then obtain a disc with a diameter of 12mm and a thickness of 0.9mm by compression molding, deglue at 600°C, and finally sinter at 1180°C for 2 hours to form a ceramic composite with the above formula.

[0062] The ceramic disc was polished with fine sand, coated with silver paste on both surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com