Porous organic-inorganic composite material and method for preparing same

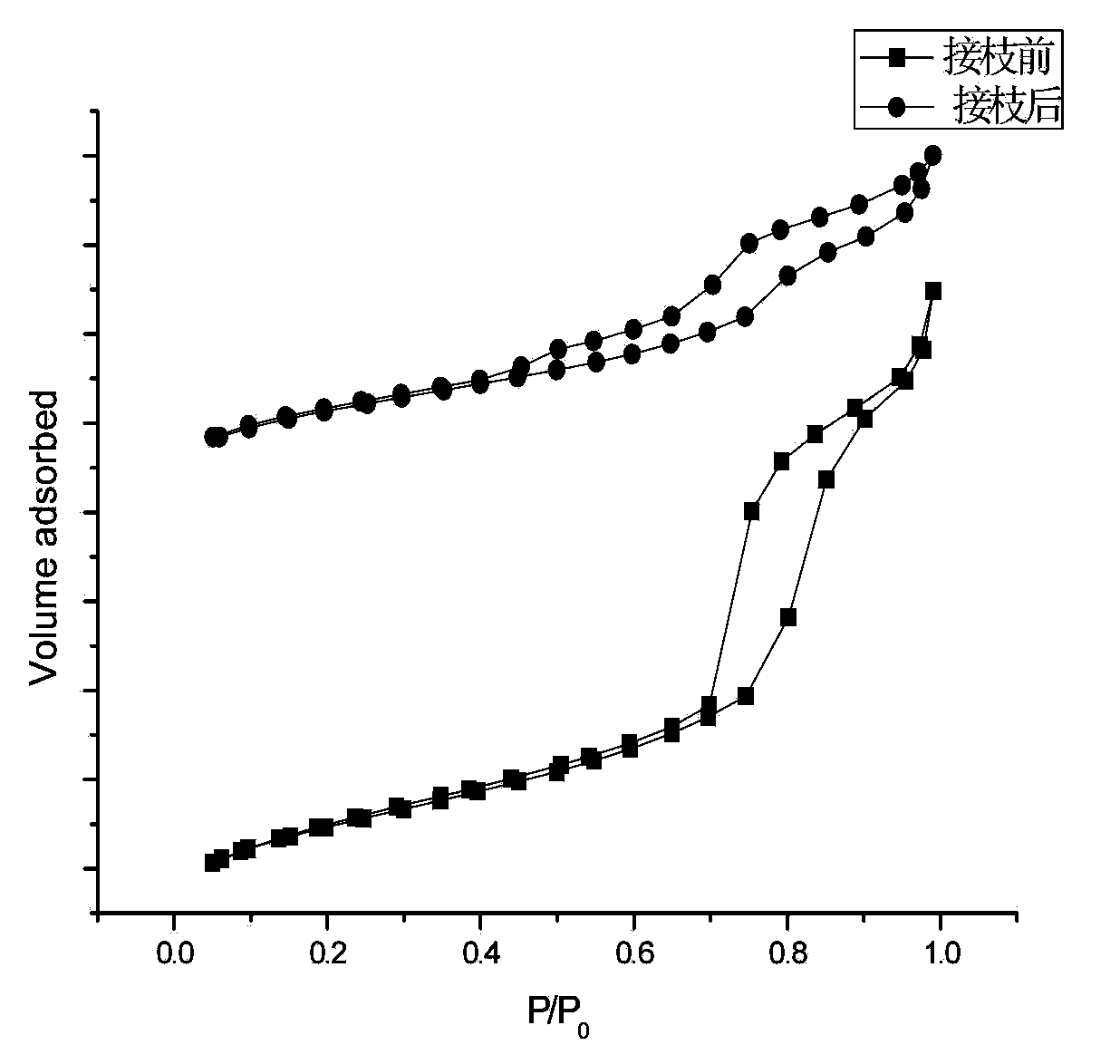

An inorganic composite material and organic technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of large capillary size, harsh reaction conditions, and limited application range, and achieve the effects of convenient operation, easy-to-obtain raw materials, and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a novel porous organic-inorganic composite material, which includes the following steps:

[0035] 1. Synthesis of functional organic compounds

[0036]Heat the dry Schrank tube to vacuum, replace nitrogen to remove oxygen, cool, take 20mL dichloromethane, 3.28mL (23.5mmol) triethylamine, 2.52mL butenol into the Schrank tube, and place in ice water Cool to 0°C, add bromoisobutyryl bromide dropwise, stir in an ice-water bath for 3 h, then stir at room temperature for 12 h; use a rotary evaporator to evaporate under reduced pressure, wash with 3N hydrochloric acid, and then wash with saturated NaHCO 3 aqueous solution, and finally with deionized water, followed by anhydrous Na 2 SO 4 Dried, passed nuclear magnetic detection, nuclear magnetic detection data: 1 H NMR (CDCl 3 , Me 4 Si): δ1.93(s, 6H), 2.42-2.48(m, 2H), 4.23(t, J=6Hz, 2H), 5.12(t, J=12Hz, 2H), 5.74-5.86(m, 2H ).) Determine the product structure as follows, ...

Embodiment 2

[0052] This embodiment provides a preparation method of a novel porous organic-inorganic composite material, which is grafted by direct reaction between the hydroxyl group on the surface of the silica vesicle and a functional group (such as a carboxyl group), and the reaction equation is as follows:

[0053]

[0054] The preparation method provided in this embodiment comprises the following steps:

[0055] 1. Add 1.2g of silica vesicle material (0.02mol) to a dry Schrank tube, vacuumize, heat to remove water, replace nitrogen to remove oxygen, and cool; add 30ml THF, 0.66g, to the Schrank tube α-Bromoisobutyric acid (0.004mol), heated to 87°C in an oil bath, and refluxed for 15h;

[0056] 2. Stop heating, wait for the Schrank tube to cool down, transfer the mixture in the tube to a centrifuge tube and add acetone for centrifugation (3500r / min, 3min), remove the supernatant, then wash with acetone, centrifuge, repeat 5 times;

[0057] 3. Remove volatile substances under red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com