Strong force rotary pressing molding method of nanocrystalline/superfine crystal carbon steel cylindrical piece

A technology of strong spinning and cylindrical parts, which is applied in the strong spinning forming of nanocrystalline/ultrafine-grained carbon steel cylindrical parts, and the field of nano/ultrafine-grained materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

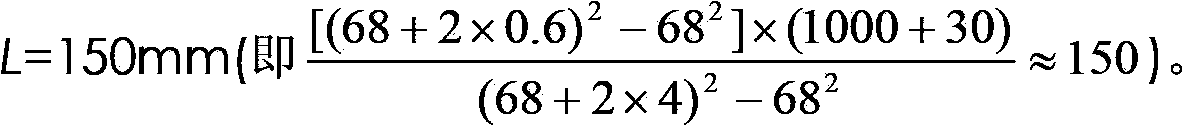

[0042] A low-carbon steel metal thin-walled cylindrical part, the material is 10 steel (0.1% carbon content), the shape is as figure 1 As shown, the diameter of the inner cavity of the cylindrical piece is d=68mm, the wall thickness δ=0.6mm, and the length l=1000mm. In addition to shape requirements, it is also necessary to obtain an ultrafine-grained microstructure with a grain size of less than 1 μm.

[0043] 1. Since the specifications can be purchased in the market as The seamless steel pipe, the diameter of the inner cavity of the cylindrical part is d=68mm, and the wall thickness is Δ=4mm. If the seamless steel pipe of this specification is used to form the part, the wall thickness should be reduced from 4mm to 0.6mm, and the thinning rate is 85%. Therefore, the part is intended to pass through the seamless steel pipe blank (such as Figure 4 shown) processed by multi-pass spinning forming and recrystallization treatment (such as Figure 8 shown). The raw material ...

Embodiment 2

[0051] A low-carbon steel metal thin-walled cylindrical part, the material is 10 steel (0.1% carbon content), the shape is as figure 1 As shown, the diameter of the inner cavity of the cylindrical piece is d=69mm, the wall thickness δ=0.6mm, and the length l=1000mm. In addition to shape requirements, it is also necessary to obtain an ultrafine-grained microstructure with a grain size of less than 1 μm.

[0052] 1. The inner diameter of this part is d=69mm. There is no similar seamless steel pipe on the market. Figure 5 shown) as a spinning blank, and then processed by multi-pass spinning forming and recrystallization treatment (such as Figure 8 shown). The tube raw material is in an annealed state, its grain shape is equiaxed, and its grain size is 30-50 μm, such as Figure 9 shown.

[0053] The wall thickness of the cup-shaped blank is determined to be Δ=4mm according to the requirement of a total thinning rate of 85%. Therefore, a steel plate with a thickness of the cu...

Embodiment 3

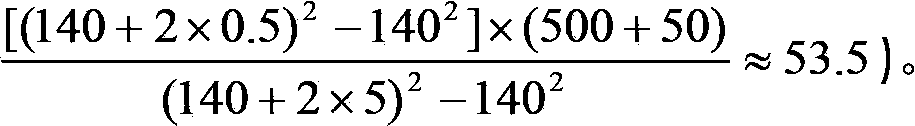

[0059] A low-carbon steel metal thin-walled cylindrical part, the material is 25 steel (0.25% carbon content), the shape is as figure 1 As shown, the diameter of the inner cavity of the wall cylindrical part is d=140mm, the wall thickness δ=0.5mm, and the length l=500mm. In addition to shape requirements, it is also necessary to obtain an ultrafine-grained microstructure with a grain size of less than 1 μm.

[0060] 1. Since the specifications can be purchased in the market as seamless steel pipe, the inner diameter of the seamless steel pipe is d=140mm, and the wall thickness of the seamless steel pipe is Δ=5mm. If the seamless steel pipe of this specification is used to form the part, the wall thickness should be reduced from 5mm to 0.5mm, and the thinning rate is 90%. Therefore, the part is intended to pass through the seamless steel pipe blank (such as Figure 4 shown) processed by multi-pass spinning forming and recrystallization treatment (such as Figure 8 shown). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com