Leakage detection method for waste heat recovery device of ascension pipe of coke-oven raw gas

A waste heat recovery device and leakage detection technology, applied in coking ovens, by measuring the rate of increase and deceleration of fluid, and using liquid/vacuum degree for liquid tightness measurement, etc., can solve accidents, affect normal production, and cannot work normally. problems, to reduce impact and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

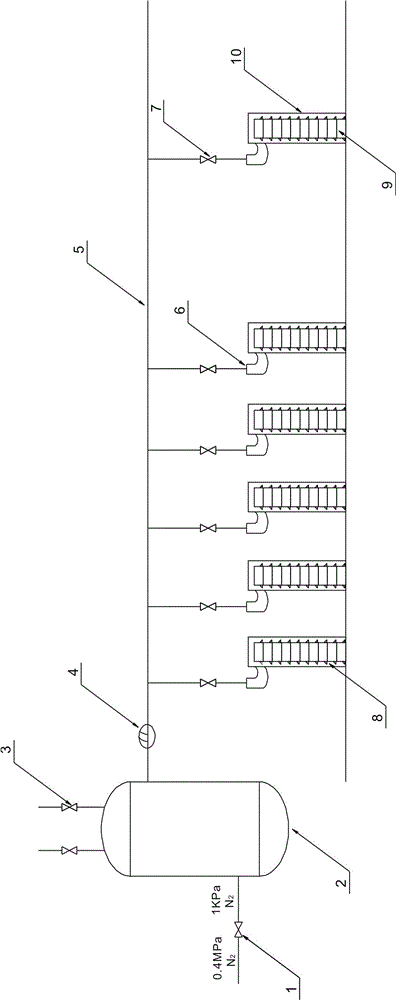

[0013] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, the leakage detection method of a coke oven raw gas riser waste heat recovery device in this embodiment is aimed at multiple riser waste heat recovery devices, and the riser waste heat recovery device includes an inner cylinder 9, an outer cylinder 10 and a coil 8 , between the inner cylinder 9 and the outer cylinder 10 is an annular cavity, the annular cavity is filled with solid powder heat transfer medium and filled with inert gas, the inert gas in this embodiment is nitrogen, and the coil 8 is arranged in the above-mentioned annular cavity Inside, the coil 8 is a heat exchange medium such as water or heat transfer oil. Its leak detection method comprises the following steps:

[0015] 1) Connect the annular cavity of each riser waste heat recovery device to the summary main pipe 5 through the branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com