Limiting rope and making method thereof

A production method and rope technology, applied in the field of rope, can solve the problems of low strength of the whole rope, potential safety hazards, poor wear resistance of the rope body and eye rings, etc., and achieve the effects of strong integration, prolonging the service life and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

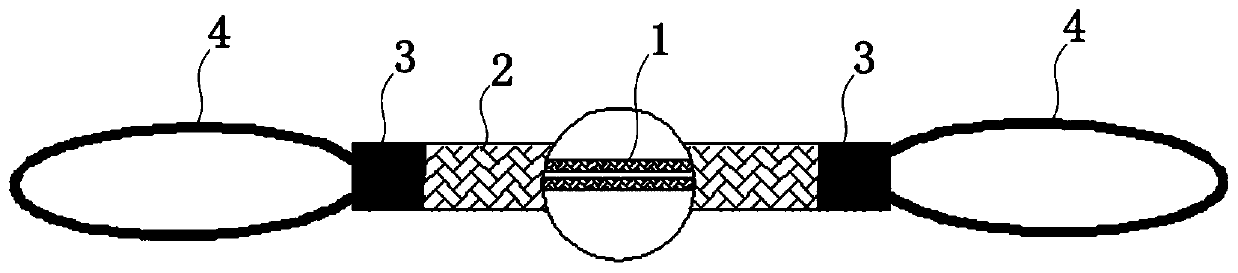

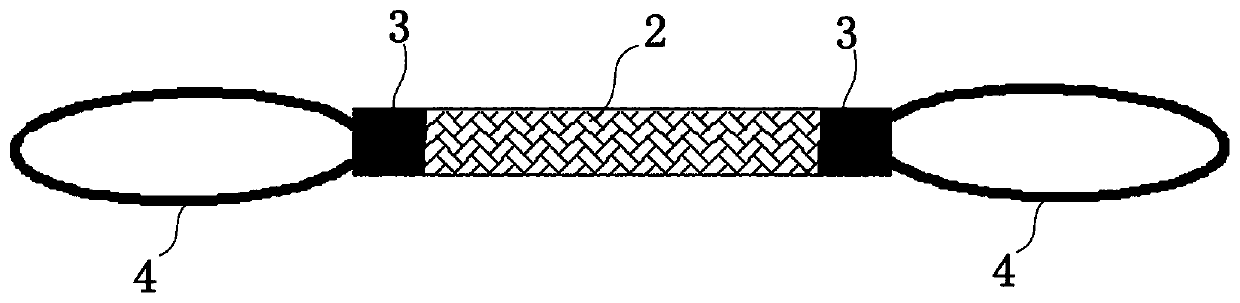

[0051] Step S11: Merge 5 ultra-high molecular weight polyethylene fibers with a specification of 1600D into 1 strand, and twist during the process of doubling.

[0052] Step S12: using a 320 braiding machine to braid 6 strands of S twist and 6 strands of Z twist into a rope core with a pitch of 9 times.

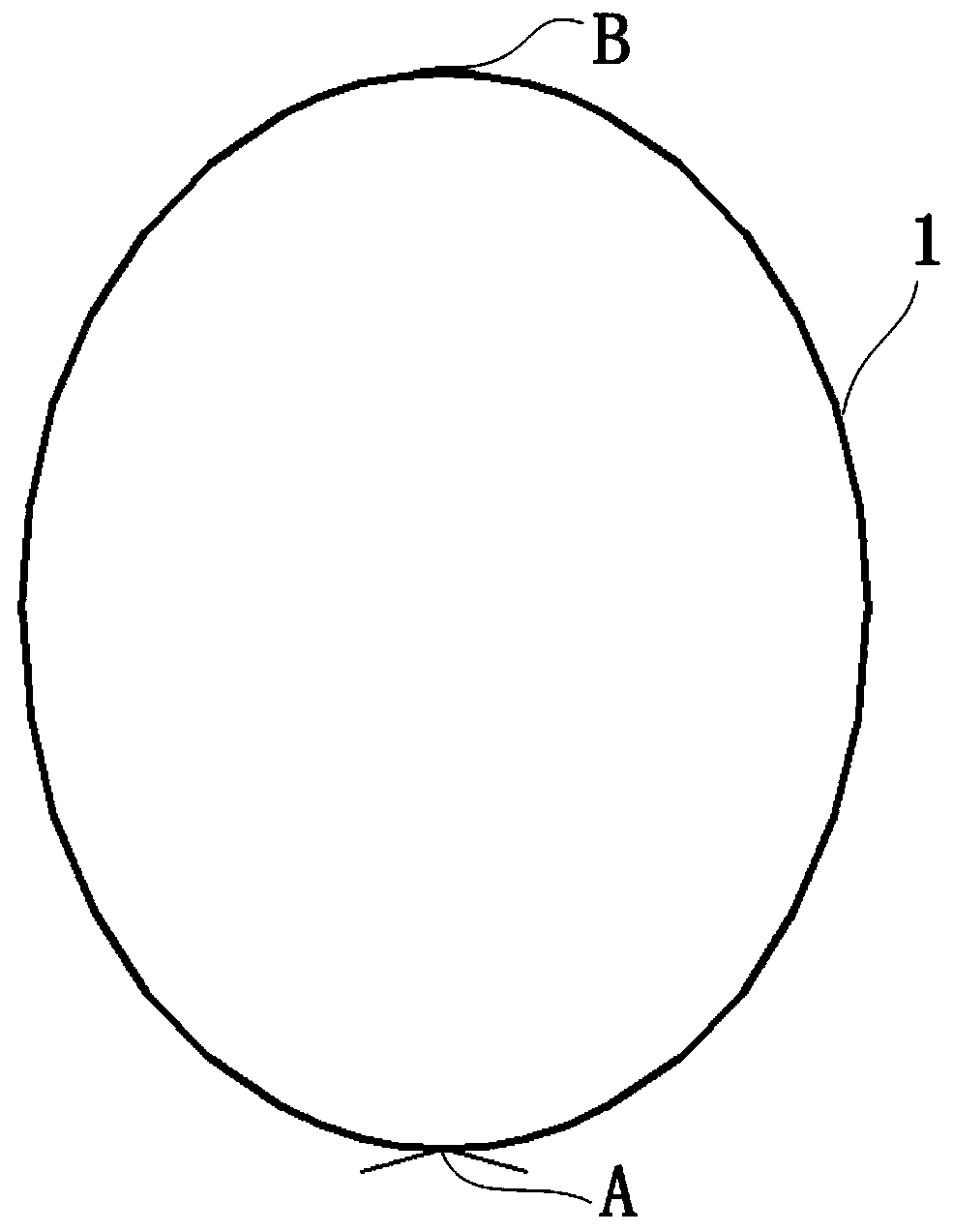

[0053] Step S13: Take a braided rope core and fold it in half, and mark the first half-fold point at the half-fold point, then make a second half-fold point, and mark two second half-fold points at the second half fold point. The rope ends on both sides of the first pair of folding points respectively pass through the inner side of the rope core from the second pair of folding points on the opposite side, and then both pass through the first pair of folding points, thereby forming an endless rope.

[0054] Step S21: Twist the nylon fiber with a specification of 840D through the twisting machine. The transmission belt of the twisting machine is tight and tight. The tension of ...

Embodiment 2

[0060] Step S11: merging 7 aramid fibers with a specification of 1500D into 1 strand, and twisting during the merging process.

[0061] Step S12: using a 320 braiding machine to braid 6 strands of S twist and 6 strands of Z twist into a rope core with a pitch of 9 times.

[0062] Step S13: Take a braided rope core and fold it in half, and mark the first half-fold point at the half-fold point, then make a second half-fold point, and mark two second half-fold points at the second half fold point. The rope ends on both sides of the first pair of folding points respectively pass through the inner side of the rope core from the second pair of folding points on the opposite side, and then both pass through the first pair of folding points, thereby forming an endless rope.

[0063] Step S21: Twist the aramid fiber with a specification of 1500D through the twisting machine. The transmission belt of the twisting machine is tight and tight. The tension of each fiber must be adjusted thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com