Current assisted method for quickly preparing powder

A powder and fast technology, applied in the field of current-assisted rapid powder preparation, to achieve fast powder reaction, simple design, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, the method of current-assisted rapid preparation of powder is as follows:

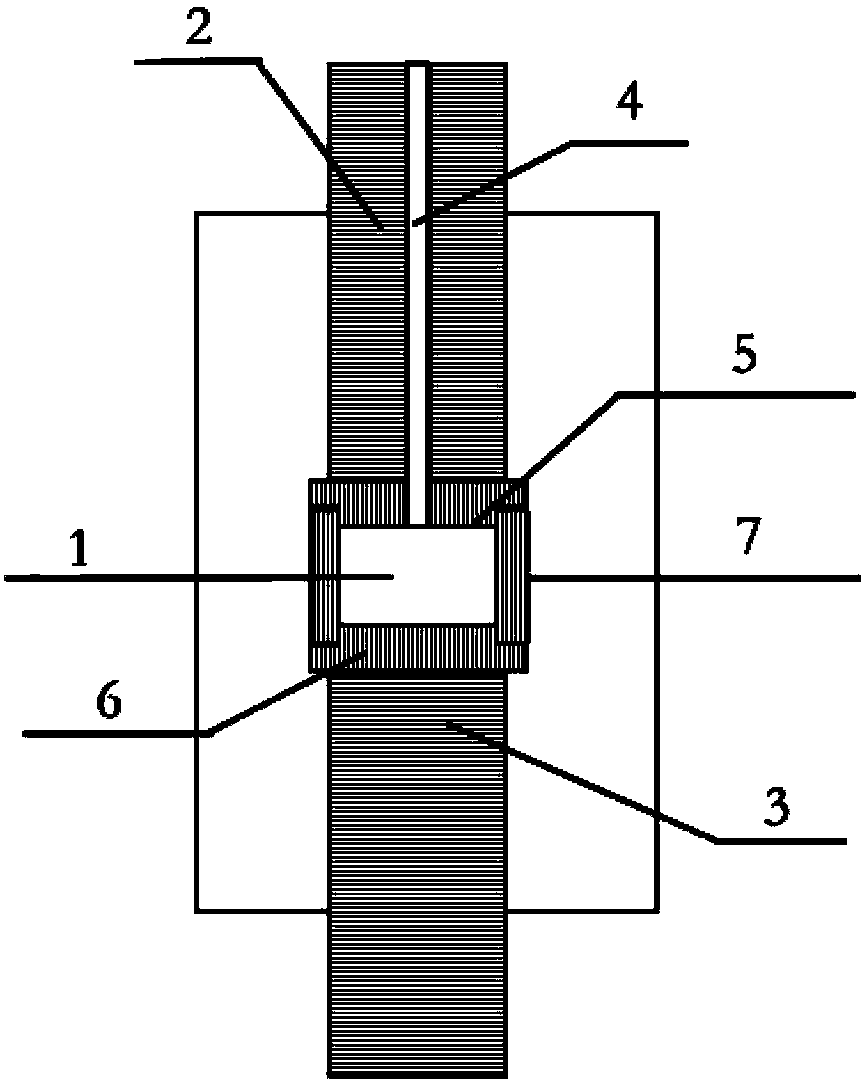

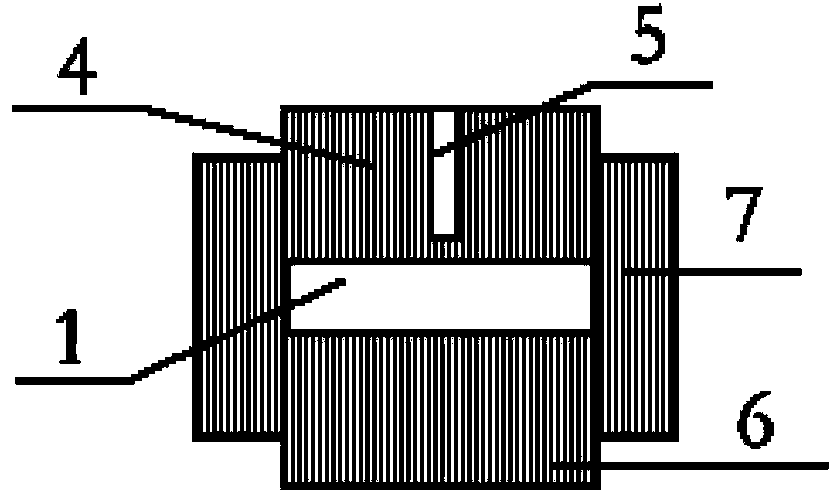

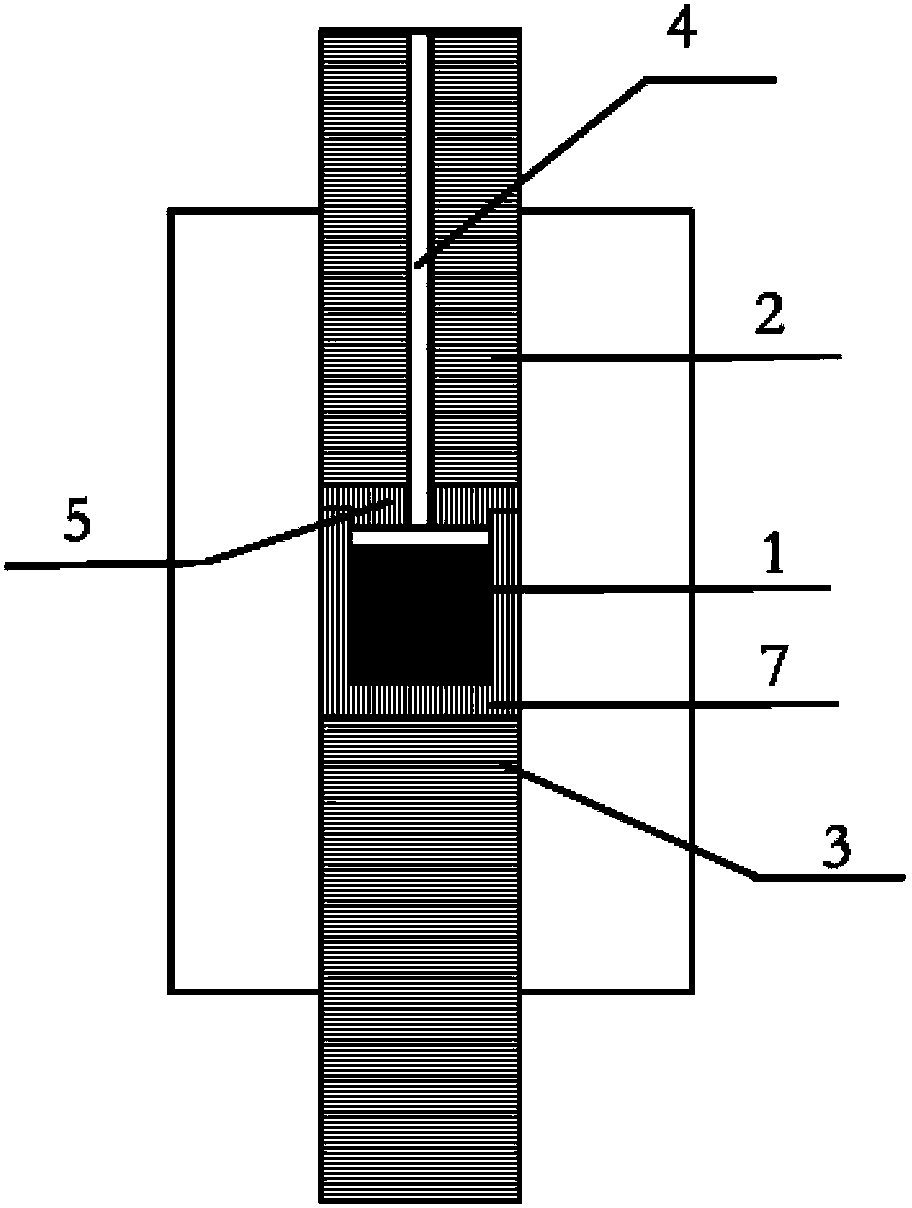

[0036] A current-assisted rapid powder preparation device is used, and the structural schematic diagram of the device is shown in image 3 As shown, it includes a reaction chamber 1 for placing powder, upper and lower electrode pressure heads 2 and 3 connected to the reaction chamber 1 . The reaction chamber 1 is a closed space surrounded by the chamber side wall 7, the upper end cover 5 and the lower end cover 6, the upper end cover 5 is connected with the upper electrode pressure head 2, the lower end cover 6 is connected with the lower electrode pressure head 3, and The volume of this enclosed space is fixed. The upper end cover 5 is provided with a temperature measuring hole 4 for placing a temperature measuring component to monitor the temperature in the reaction chamber 1, and the temperature measuring component is an upper infrared thermometer. Such as Figure 4 As sho...

Embodiment 2

[0043] In this example, the method of current-assisted rapid preparation of powder is as follows:

[0044] A current-assisted rapid powder preparation device is used, and the structural diagram of the device is similar to image 3 As shown, it includes a reaction chamber 1 for placing powder, upper and lower electrode pressure heads 2 and 3 connected to the reaction chamber 1 . The reaction chamber 1 is a closed space surrounded by the side wall 7 of the chamber, the upper end cover 5 and the lower end cover 6, the upper end cover 5 is connected with the upper electrode pressure head 2, the lower end cover 6 is connected with the lower electrode pressure head 3, and The volume of this enclosed space is fixed. The upper end cover 5 is provided with a temperature measuring hole 4 for placing a temperature measuring component to monitor the temperature in the reaction chamber 1, and the temperature measuring component is an upper infrared thermometer. Such as Figure 5 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com