Overlength afterglow luminescent glass particle and preparation method thereof

A technology of glass particles and luminous glass, which is applied in the field of building materials, can solve the problems of affecting the reflective effect, glass beads are easy to absorb dust, and lose luminous performance, etc., to achieve good luminous effect, excellent hydrophilicity, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

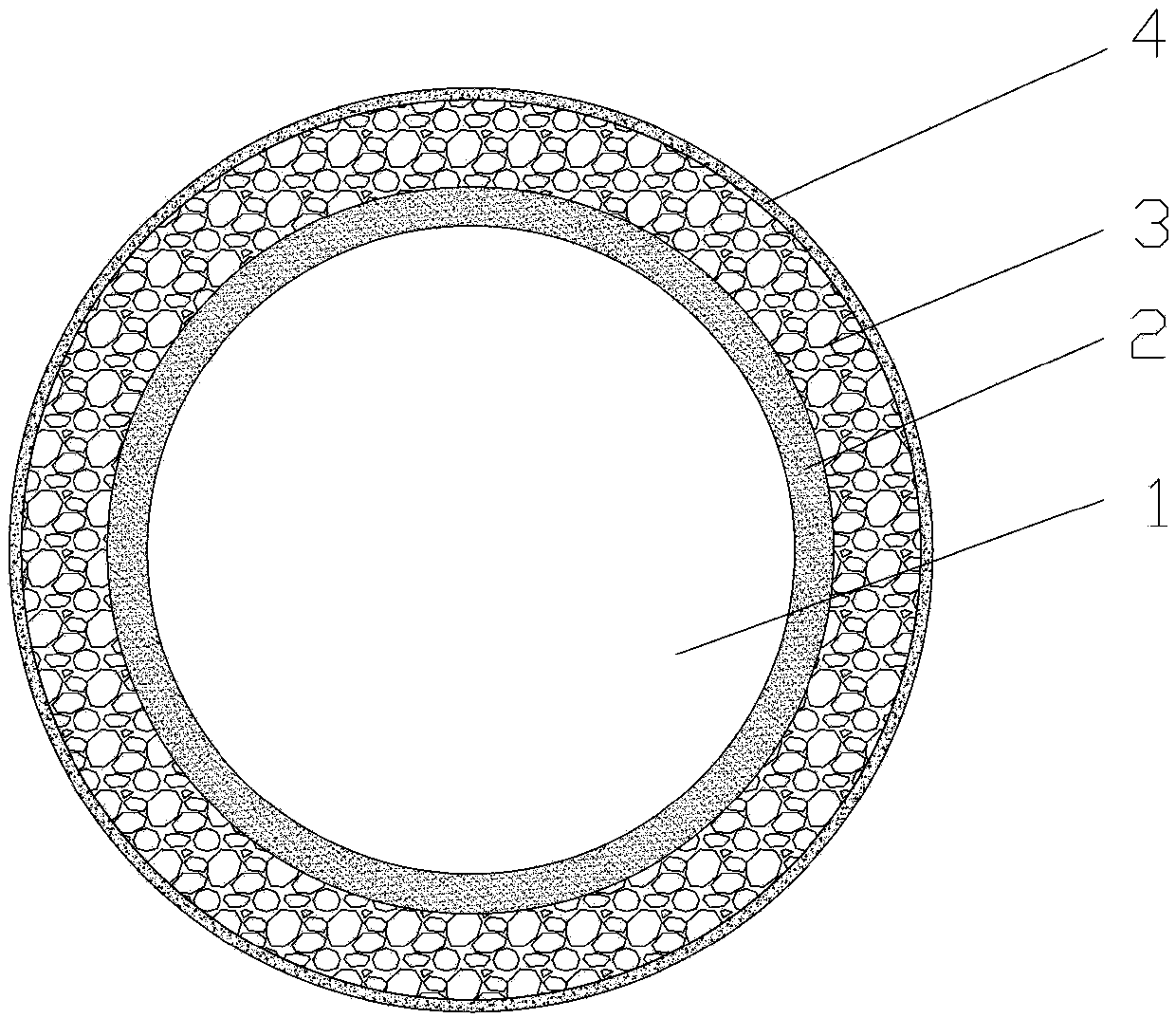

[0022] A method for preparing ultra-long afterglow luminescent glass particles, the specific steps are as follows:

[0023] 1) Preparation of resin raw materials: Weigh unsaturated polyester resin or epoxy resin 300-1000, add methyl ethyl ketone peroxide 0.4-12, coupling agent 0.4-12, fully stir with a stirrer for 20 minutes for later use;

[0024] 2) Put 10000 transparent colorless glass particles in the mixer, take the mixed resin 400-600 into the glass particles, mix well, so that the outer surface of the glass particles is evenly coated with a layer of resin;

[0025] 3) Weigh 600-800 luminescent powder in the mixer, fully mix the glass particles coated with resin layer and luminescent powder, until the outer surface of the glass particles is covered with a layer of luminescent powder;

[0026] 4) Send the glass particles coated with luminescent powder in step 3) into an oven at a temperature of 50°C-80°C, and keep warm for one hour to cure;

[0027] 5) Add 50-500 unsatur...

Embodiment 1

[0031] A method for preparing ultra-long afterglow luminescent glass particles, the specific steps are as follows: by weight (g / part)

[0032] 1) Preparation of resin raw materials: Weigh 7934-2300g of unsaturated polyester resin, add 0.4g of methyl ethyl ketone peroxide, 0.4g of coupling agent KH-5700, solidify at room temperature, then add 0.2g of cobalt isooctanoate, stir fully with a stirrer for 20 minutes spare;

[0033] 2) Put 10,000g of transparent colorless glass particles in the mixer, take 400g of the mixed resin and add it to the glass particles, mix well, so that the outer surface of the glass particles is evenly coated with a layer of resin;

[0034] 3) Weigh 600g of luminescent powder in a stirrer, fully mix the resin-coated glass particles and luminescent powder until the outer surface of the glass particles is covered with a layer of luminescent powder;

[0035] 4) Send the glass particles coated with luminescent powder in step 3) into an oven at a temperature...

Embodiment 2

[0039] A method for preparing ultra-long afterglow luminescent glass particles, the specific steps are as follows: by weight (g / part)

[0040] 1) Preparation of resin raw materials: Weigh 1000g of unsaturated polyester resin 7935, add 12g of methyl ethyl ketone peroxide, 12g of coupling agent, fully stir with a stirrer for 20 minutes and set aside;

[0041] 2) Put 10,000g of transparent colorless glass particles in the mixer, take 600g of the mixed resin and add it to the glass particles, mix well, so that the outer surface of the glass particles is evenly coated with a layer of resin;

[0042] 3) Weigh 800g of luminescent powder in a stirrer, fully mix the resin-coated glass particles and luminescent powder until the outer surface of the glass particles is covered with a layer of luminescent powder;

[0043] 4) Send the glass particles mixed in step 3) into an oven at a temperature of 80°C, and keep them warm for one hour to solidify;

[0044] 5) Add 7,935,500 g of unsaturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com