Graphene-loaded lamellar cupric oxide composite material and hydro-thermal synthesis method thereof

A composite material and hydrothermal synthesis technology, which is applied in the field of electrochemistry and material synthesis, can solve the problems of easy agglomeration of copper oxide materials, low power density, long charging time, etc., and achieve short preparation cycle, improved capacitance performance, and large output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

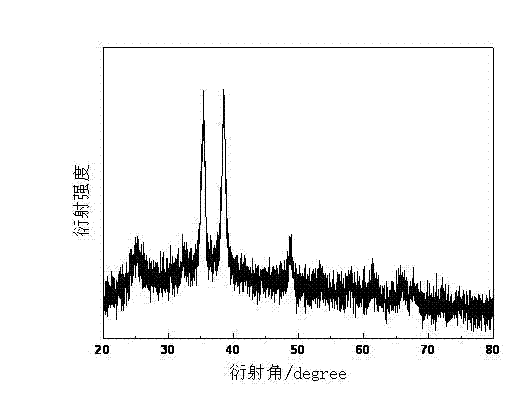

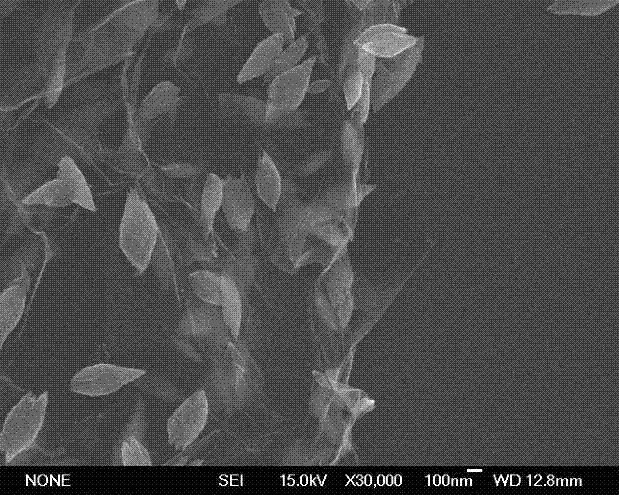

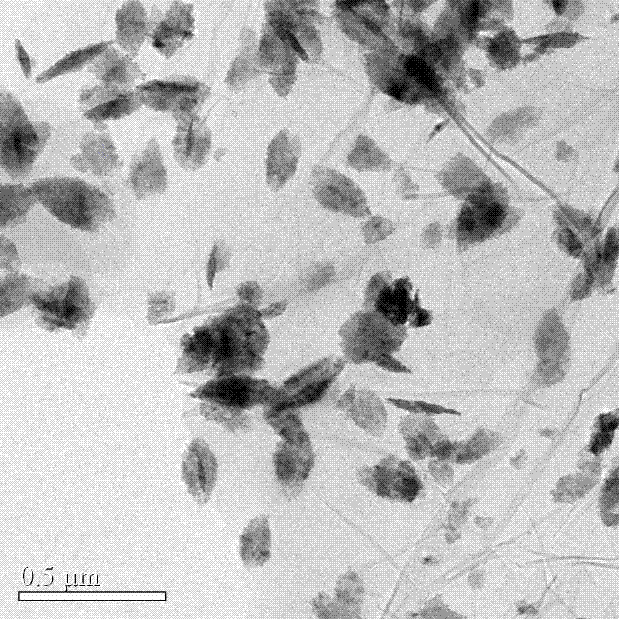

[0031] Example one : Using copper nitrate as the copper source to prepare graphene-supported flake copper oxide composite materials.

[0032] Put potassium persulfate (K 2 S 2 O 8 ) 2.5 g, phosphorus pentoxide (P 2 O 5 ) 2.5 g, dissolved in 12 mL of concentrated sulfuric acid, heated to 80°C; then 3 g of natural graphite was added to the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500 mL of deionized water, and allowed to stand overnight ; Filter, use a 0.2 mm filter to float off the residual acid; dry in a vacuum oven at 60℃; add the obtained pre-oxide to 120 mL of concentrated sulfuric acid in an ice bath, and slowly add 15 g of KMnO with stirring 4 , Keep the temperature below 20°C during the addition. Then the temperature was controlled at 35°C and stirred for 2 h. Add 250 mL deionized water to dilute, and keep the temperature below 50℃ in an ice bath during the dilution process. Stir for another 2 h, then add 0.7 L of deionized wate...

Embodiment 2

[0036] Example two : Using copper acetate as the copper source to prepare graphene-supported flake copper oxide composite materials.

[0037] Take 0.8 g of copper acetate into 75 mL of deionized water, add 90 mg of graphene to it, stir for 15 min, sonicate for 0.5 h, add 15 ml of 0.3M ammonium carbonate dropwise to it, and put it in the reactor at a constant temperature of 100℃6 h. Centrifugation, alcohol washing and water washing 3 times each to obtain the product. The prepared material has a capacity of 321.7 F / g measured by electrochemical testing.

Embodiment 3

[0038] Example three : Using ethylene glycol as a solution to prepare graphene-supported flake copper oxide composites.

[0039] Take 0.6 g of copper nitrate and add 70 mL of ethylene glycol, add 90 mg of graphene to it, stir for 15 min, sonicate for 0.5 h, add 20 ml of 0.3M ammonium bicarbonate dropwise to it, and put it in the reaction kettle at a constant temperature of 120 ℃ 4h. Centrifugation, alcohol washing and water washing 3 times each to obtain the product. The prepared material has a capacity of 303.0 F / g measured by electrochemical testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com