Method for preparing nanometer material mixed matrix membrane

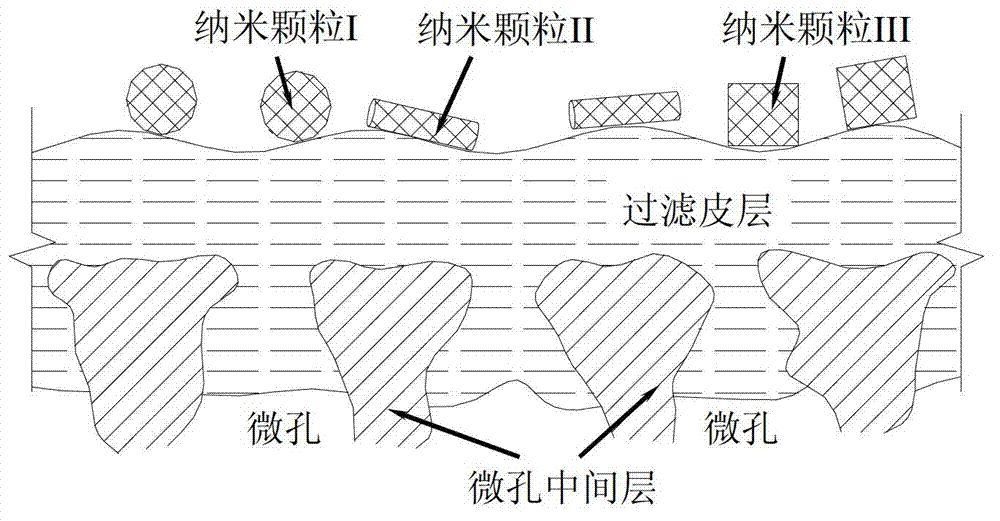

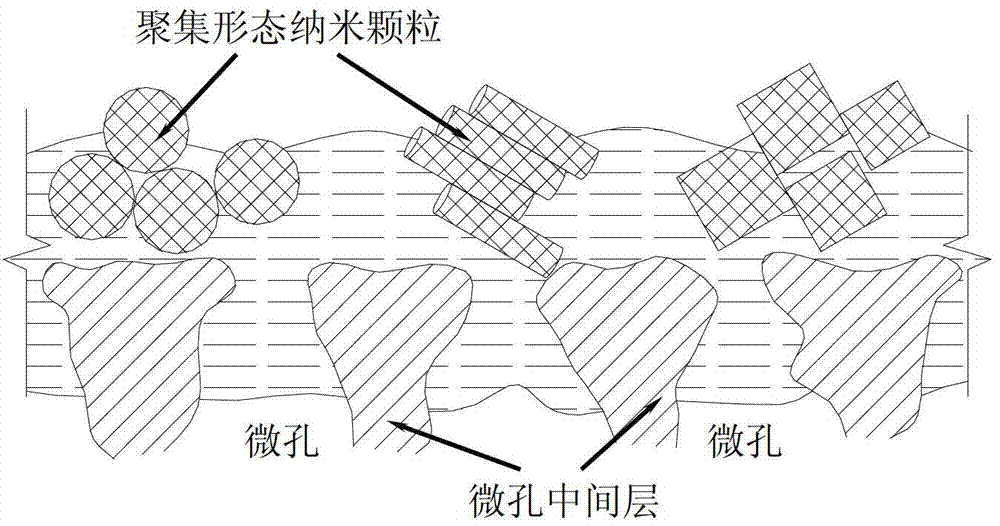

A technology of mixed matrix membranes and nanomaterials, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of difficulty in controlling the coverage of nanomaterials, easy aggregation of nanomaterials, filtration and retention performance of mixed matrix membranes Adverse effects and other issues, to achieve the effect of easy control of coverage, high firmness, and not easy to gather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

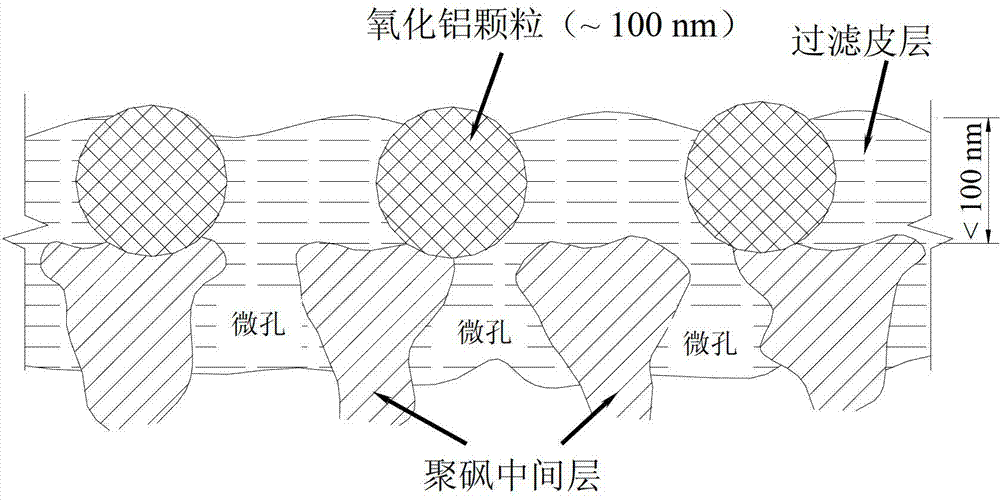

[0045] refer to image 3 , the preparation method of the present embodiment comprises two steps:

[0046] Step 1. Prepare the microporous intermediate layer implanted with nanomaterials:

[0047] The nanometer material is aluminum oxide.

[0048] In the method for implanting nanomaterials on the surface of the microporous intermediate layer in the step 1, the "in situ implantation" method is used to implant the nanomaterials on the surface of the microporous intermediate layer while preparing the microporous intermediate layer;

[0049] The material of the microporous intermediate layer is polysulfone PSf, and the average particle diameter of the particles is 100 nanometers.

[0050] Step 2, preparing a filter cortex on the surface of the microporous middle layer implanted with nanomaterials.

[0051] The "in situ implantation" method is: while preparing the microporous interlayer, the nanomaterial is implanted in situ on the surface of the microporous interlayer, which can b...

Embodiment 2

[0061] refer to Figure 4 , the preparation method of the present embodiment comprises two steps:

[0062] Step 1, preparing a microporous intermediate layer implanted with nanomaterials;

[0063] The microporous interlayer is prepared by "non-solvent-induced phase separation method NIPS", and then the nanomaterials are implanted on the surface of the microporous interlayer by "physical coating method";

[0064] The microporous intermediate layer material is polyetherimide PEI, and the nanometer material is carbon nanotubes, the average length of carbon nanotubes is 200 nanometers, and the average diameter is 1 nanometer.

[0065] The "non-solvent-induced phase separation method" for preparing the microporous intermediate layer is implemented in this embodiment as follows: 18 grams of polyetherimide is dissolved in 82 grams of dimethylformamide DMF to form a casting solution ; Before film formation, the casting solution is evenly coated on the non-woven polyester cloth with ...

Embodiment 3

[0075] refer to Figure 5 , the preparation method of the present embodiment comprises two steps:

[0076] Step 1, preparing a microporous intermediate layer implanted with nanomaterials;

[0077] While preparing the microporous middle layer, the "in situ implantation" method is used to implant nanomaterials into the surface of the microporous middle layer;

[0078] The material of the microporous intermediate layer is polysulfone PSf, the nano material is zeolite, and the average particle size of the particles is 100 nanometers.

[0079] The microporous intermediate layer is prepared by the non-solvent-induced phase separation method NIPS: 18 grams of polysulfone is dissolved in 82 grams of N-methylpyrrolidone NMP to form a casting solution; before film formation, the casting solution is evenly coated The cloth is on the non-woven polyester cloth, and the thickness is 100 microns; The non-solvent phase is water containing 0.15% nanometer zeolite particles in mass ratio, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com