Method for preparing quick-responding thermo-sensitive porous microspheres based on microfluidic technology

A microfluidic technology and fast response technology, applied in the field of preparation of temperature-sensitive porous microspheres, can solve problems such as uneven particle size of microspheres, and achieve adjustable temperature response time, controllable size, and adjustable shrinkage volume ratio control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of blank temperature-sensitive microspheres: the microfluidic chip used in the preparation, its structure is as follows figure 1As shown, the monomer injection pool 2 and the initiator injection pool 3 are connected together through a microfluidic channel, and communicate with the microdroplet formation and polymerization channel 4, and the outer oil phase injection pool 1 is connected through a ring microfluidic channel. The control channel is connected with the micro-droplet formation and polymerization channel 4, and finally the micro-droplet formation and polymerization channel 4 is connected with the collection pool 5 located at the other end of the microfluidic control chip. First, the upper microfluidic chip is prepared by soft lithography technology, and the upper PDMS microfluidic chip and the lower substrate are irreversibly sealed together by oxygen plasma. The surface of the channel is then modified by hydrophobization to enable the formation of ...

Embodiment 2

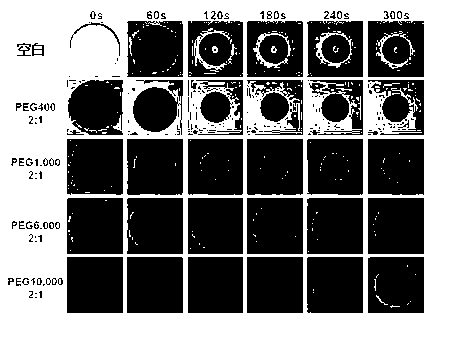

[0036] Preparation of porous temperature-sensitive microspheres formed by polyethylene glycol 1,000 molecules at a concentration of 1:1 (polyethylene glycol 1,000: N-isopropylacrylamide), based on the microfluidic chip produced in Example 1 Proceed: Add 1,000 molecules of polyethylene glycol to the monomer solution, and its mass is twice that of N-isopropylacrylamide. Add 0.4 g of polyethylene glycol 1,000 to it, and dissolve it as a monomer solution. Among them, the flow rate of the monomer and initiator was adjusted to 0.5 μL / min, and the flow rate of the oil phase (FC-40) was adjusted to 1.2 μL / min. The synthesized microspheres were taken out from the collection pool 5, and then soaked in deionized water for 3 day, and change the water at regular intervals to remove the polyethylene glycol molecules dissolved from the microspheres, and the obtained porous thermosensitive microspheres are investigated in the same way as above for thermosensitive properties (such as Figure ...

Embodiment 3

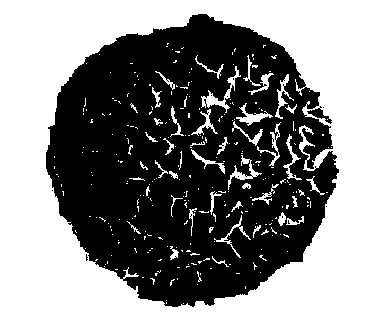

[0039] Prepare different fast-response temperature-sensitive porous microspheres with the same molecular weight and different concentrations of polyethylene glycol: on the basis of Example 2, 10,000 molecules of polyethylene glycol with 3 different concentrations were added to the monomer solution, which was mixed with N- The mass ratios of isopropylacrylamide are 0.5:1, 1:1, and 2:1, that is, when a 1mL solution is prepared, 0.2g of N-isopropylacrylamide, 0.1g, 0.2g, and 0.4 g Polyethylene glycol 10,000 molecules. When synthesizing microspheres, adjust the concentration of monomer and initiator to 0.5 μL / min, and the flow rate of the oil phase (FC-40) to 1 μL / min. Soak in water for 3 days, and change the water in stages to remove polyethylene glycol molecules of different concentrations, and investigate the temperature-sensitive properties of the prepared porous microspheres (such as Figure 6 and Figure 7 shown) and electron microscope scanning of the surface topography (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com