Fungi bag, manufacture method of fungi bag, and method for cultivating black fungus by using fungi bag

A black fungus and fungus bag technology, applied in the fields of botanical equipment and methods, application, horticulture, etc., can solve the problems of lack of raw materials, collapse, inability to produce, etc., and achieves black and thick color, strong vitality, and fast growth of mycelium. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

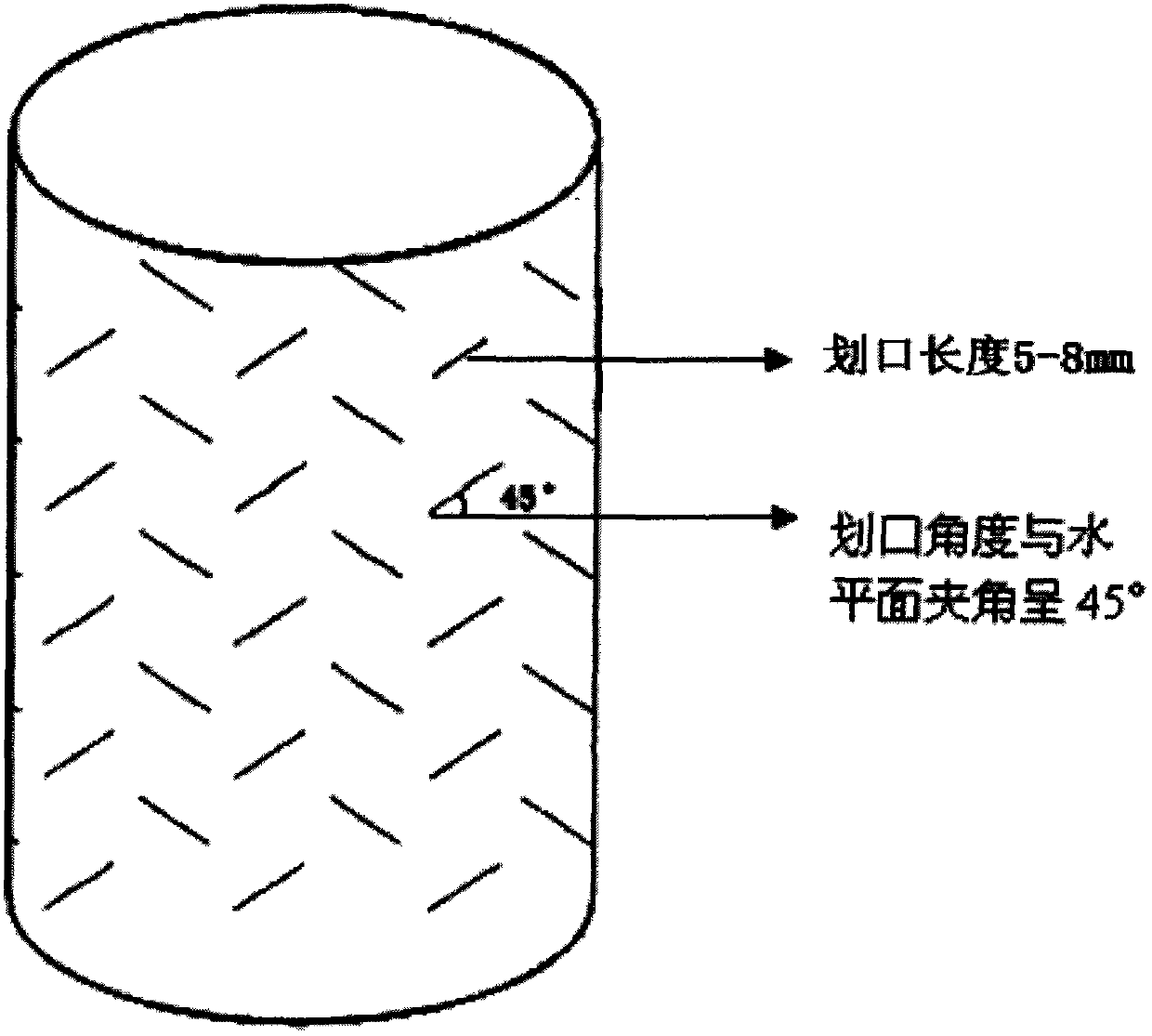

Image

Examples

Embodiment Construction

[0027] Selection of tended wood segments and twigs:

[0028] Any leftover parts of tree species other than coniferous species can be used, such as poplar, willow, birch, Mongolian oak, pentagonal maple, walnut and other broad-leaved trees common in the north. It is best to use a variety of hard miscellaneous wood chips.

[0029] Selection of granular wood chip processing machine:

[0030] Slice shredder. The working principle is to firstly chop the wood sections and branches of felling leftovers cultivated in the forest area into pieces, and then crush them into 8-20mm 3 of irregular granularity.

[0031] Simple disc saw grinder. The working principle is to assemble multiple small circular saw blades together, fix them on the main bearing, and rotate at high speed under the drive of the electric motor or diesel engine to saw the branches into 8-20mm 3 of irregular granularity.

[0032] Ingredients method

[0033] Two-thirds of the granular wood chips are made from tended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com