LED chip with stepped current blocking structure and manufacturing method thereof

An LED chip, current blocking technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of poor step coverage of transparent conductive layers and reduced electro-optical conversion efficiency of LED chips, so as to increase electro-optical conversion efficiency and improve current. Diffusion ability, the effect of improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

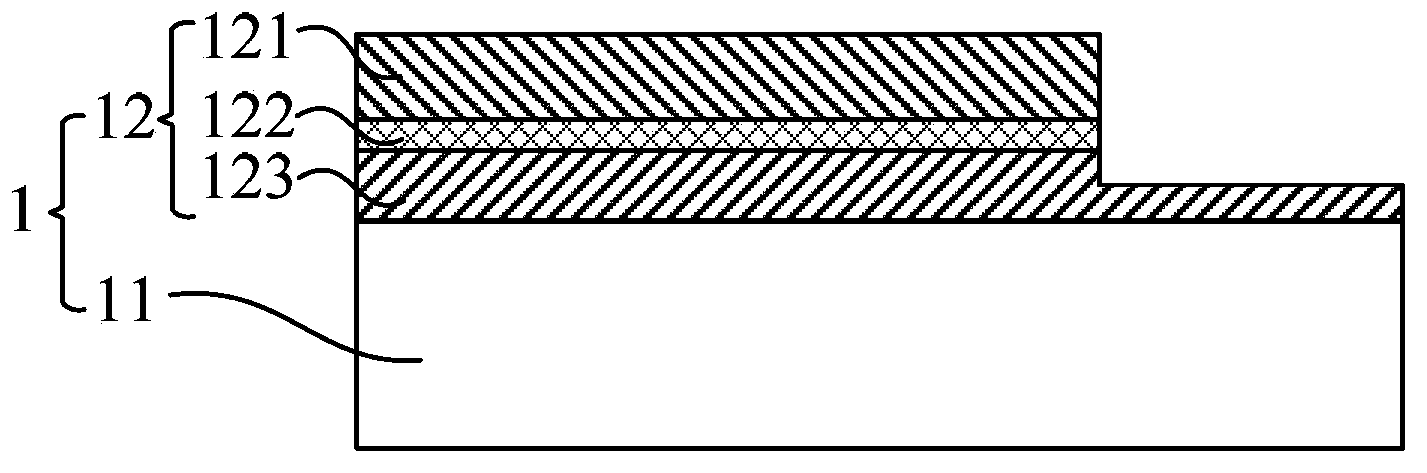

[0036] like Figure 1 to Figure 4 As shown, the present invention provides a method for manufacturing an LED chip with a stepped current blocking structure, the method at least comprising:

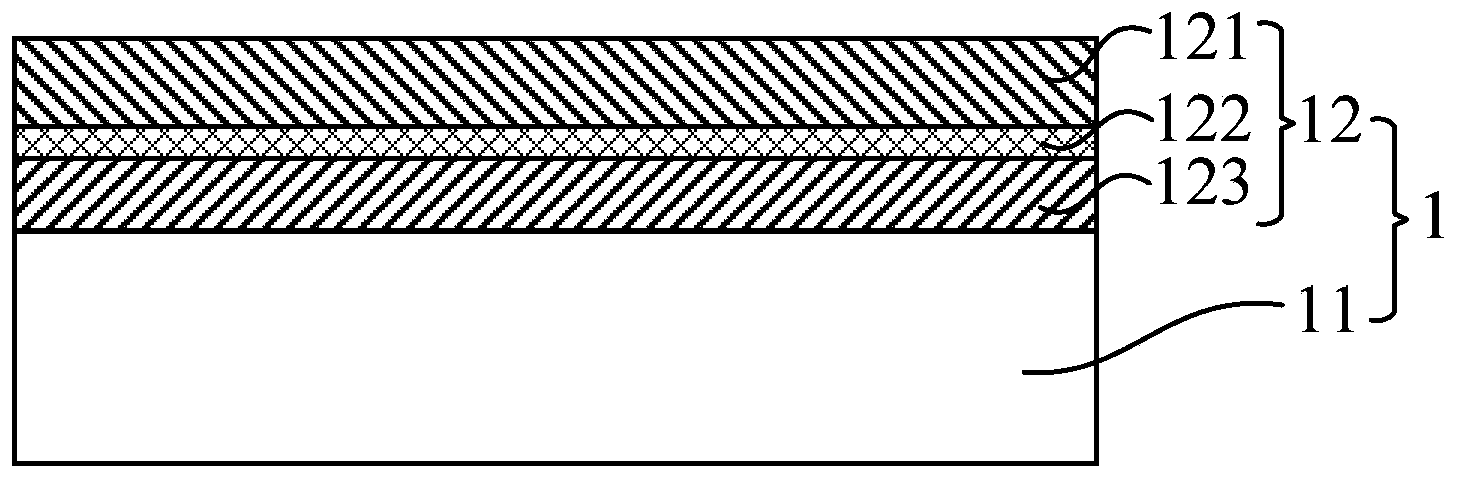

[0037] like figure 1 As shown, step 1) is first performed to provide an LED epitaxial wafer 1, the LED epitaxial wafer 1 at least includes a substrate 11 and a light-emitting epitaxial structure 12 located on the surface of the substrate, wherein the light-emitting epitaxial structure 12 consists of The first conductive type epitaxial layer 121 , the active layer 122 , and the second conductive type epitaxial layer 123 are sequentially included from bottom to bottom.

[0038] It should be pointed out that the material of the substrate 11 includes at least Al 2 o 3(sapphire), GaAs, Si, SiC, GaN, GaP, InP, ZnO, and Ge; formed on the substrate 11 by metal-organic chemical vapor deposition, molecular beam epitaxy, or hydride vapor phase epitaxy The light-emitting epitaxial structure 12; t...

Embodiment 2

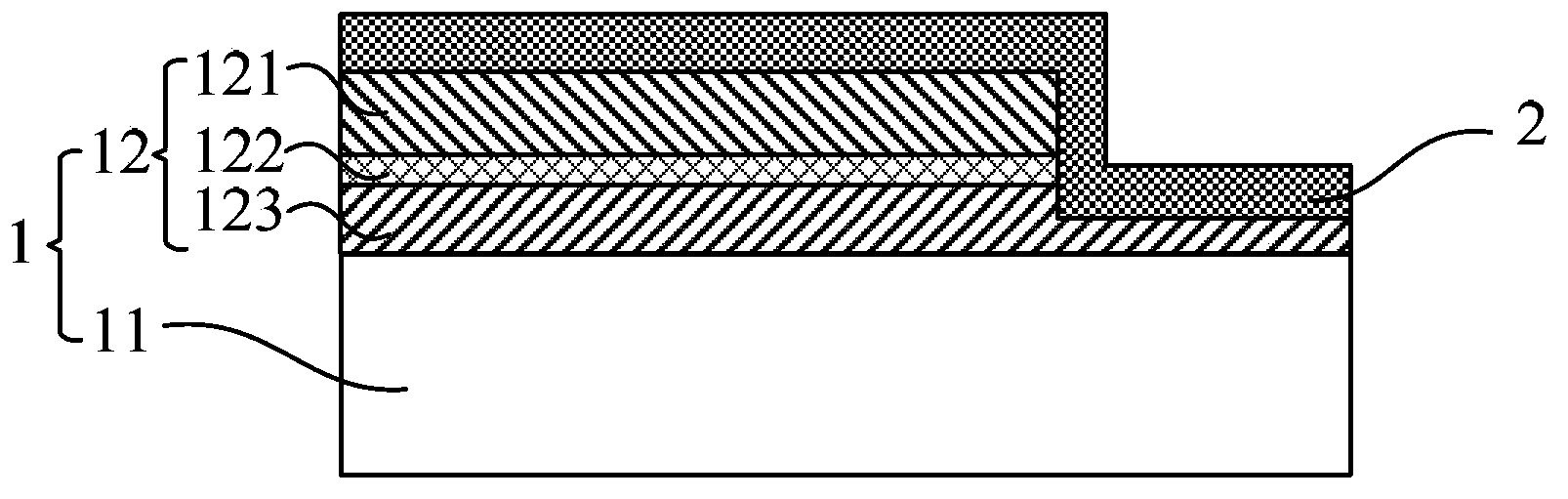

[0057] like Figure 7 As shown, the present invention also provides an LED chip with a stepped current blocking structure, the LED chip at least includes: an LED epitaxial wafer 1, a stepped current blocking structure 2, a transparent conductive layer 3, a first electrode 41, a second Electrode 42, protective layer 5.

[0058] The LED epitaxial wafer 1 at least includes a substrate 11 and a light-emitting epitaxial structure 12 located on the surface of the substrate 11, wherein the light-emitting epitaxial structure 12 includes a first conductivity type epitaxial layer 121, an active layer in sequence from top to bottom. 122, and the second conductivity type epitaxial layer 123.

[0059] Wherein, the material of the substrate 11 includes at least Al 2 o 3 (sapphire), GaAs, Si, SiC, GaN, GaP, InP, ZnO and Ge; the active layer 122 is a single quantum well structure or multiple quantum well structure, quantum dot structure or quantum wire structure ; The epitaxial layer 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com