Platinum (Pt)/reduced graphite oxide (RGO) nano composite material and preparation method and application thereof

A nanocomposite material and graphene technology, which is applied in the field of platinum/graphene nanocomposite materials and its preparation, can solve the problems of restricting the large-scale production of graphene, achieve good industrial prospects, strong safety, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

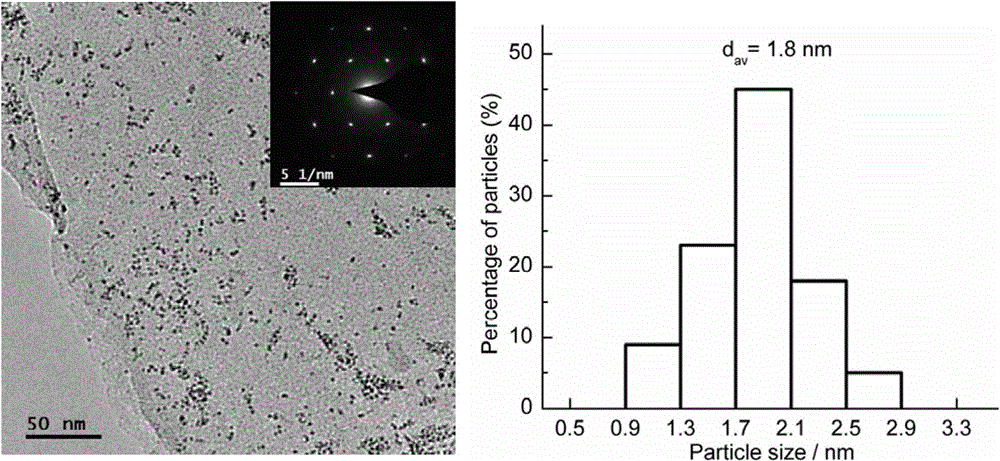

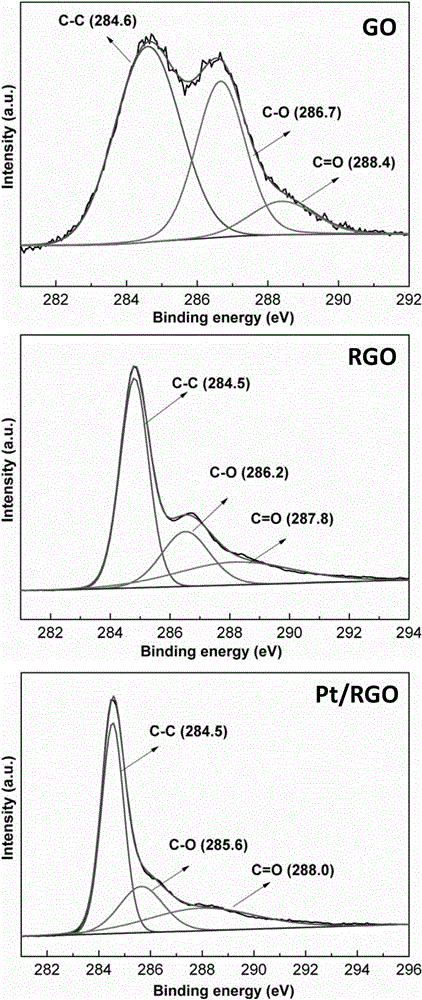

[0049] Embodiment 1, preparation Pt / RGO nanocomposite material

[0050] 1) Ultrasonic dispersion of 100mg of GO in 50mL of ethylene glycol solution, ultrasonic stripping and dispersion with an ultrasonic processor at room temperature for 1h (ultrasonic power 650W).

[0051] 2) Then add 1.773mL of 19.72g / L chloroplatinic acid solution in ethylene glycol and 48mL of 0.52mol / L sodium hydroxide solution in ethylene glycol, and mix thoroughly until the pH of the mixed solution is 12.

[0052] 3) Subsequently, transfer the mixed liquid to the irradiation tube, pass argon gas for 30 minutes to remove the oxygen in the system, seal the nozzle and place 60 Coγ-rays were irradiated at room temperature with a dose rate of 300Gy / min and an absorbed dose of 300kGy. After the irradiation, the sample was filtered through a polypropylene (PP) membrane with a pore size of 0.45 μm. The filtered filter cake is rinsed with ethanol, treated with ultrasonic waves for 5 minutes each time, and then...

Embodiment 2

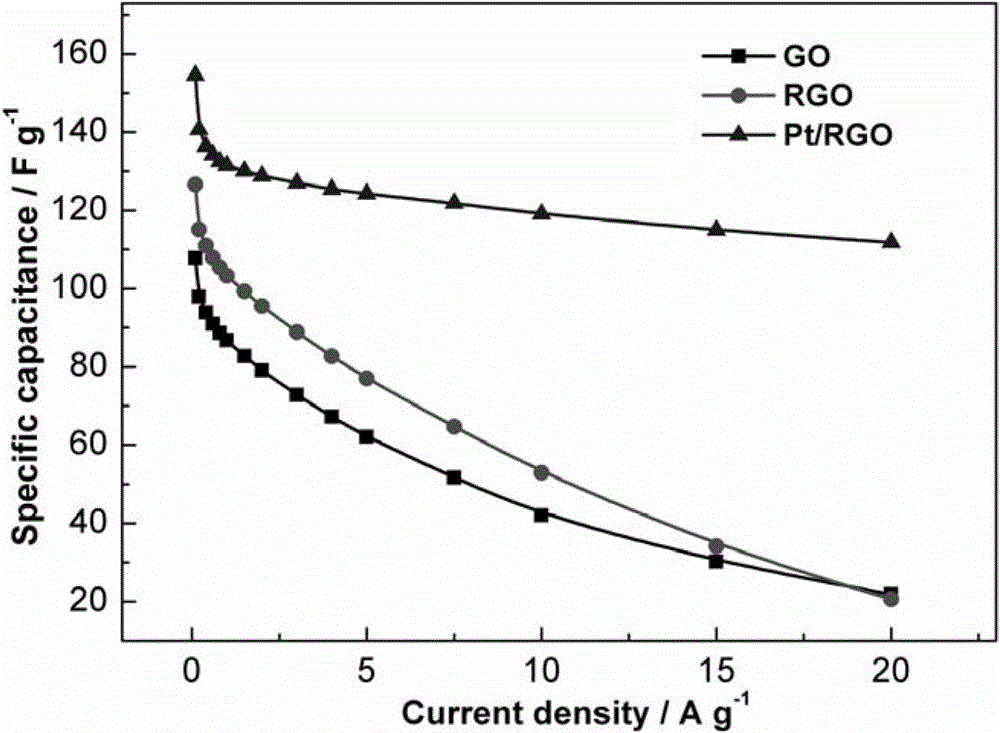

[0056] Example 2. Electrode material and electrochemical performance test using Pt / RGO nanocomposite as active component

[0057] Measurement of the specific capacitance of the Pt / RGO nanocomposite: Mix 25.5 mg of the Pt / RGO nanocomposite prepared in Example 1 with 3 mg of acetylene black and 1.5 mg of PVDF, mix evenly with a mortar, then disperse the mixture with NMP, and spread evenly On the nickel foam current collector, dry at 60°C for 4 hours, then flatten the electrode sheet with a tablet press, and then dry at 60°C for 12 hours. After weighing the dried electrode sheet, vacuum soak it in 6M KOH electrolyte for 2 hours. Then the working electrode, Hg / HgO reference electrode and graphite auxiliary electrode were assembled into a three-electrode system. At different current densities (0.05, 0.1, 0.2, 0.4, 0.6, 0.8, 1, 1.5, 2, 3, 4, 5, 7.5, 10, 15, 20, 30, 40, 50, 75, 100A / g) , Determination of constant current charge and discharge performance, measurement of cyclic volta...

Embodiment 3

[0060] Embodiment 3, preparation Pt / RGO nanocomposite material

[0061] Consistent with the reduction method of Example 1, in step 3), the electron beam radiation produced by the electron accelerator is used to induce the generation of solvent electrons and reducing free radicals as reducing agents, and the obtained RGO and Pt / RGO, wherein in Pt / RGO The loading amount of Pt is 10wt%, and the carbon-oxygen ratio is 5.2. Consistent with the method of Example 2, the electrochemical performance of the Pt / RGO nanocomposite was measured. The properties of the RGO and Pt / RGO nanocomposites prepared in this example are comparable to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com