Highly flexible cable for drag chain and manufacturing method thereof

A high-flexibility and cable technology, applied in the manufacture of high-flexible cables for drag chains and high-flexible cables for drag chains, can solve the problems of poor heat aging performance, poor electrical insulation performance, and inability to be used as cable insulation materials, etc. Good oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

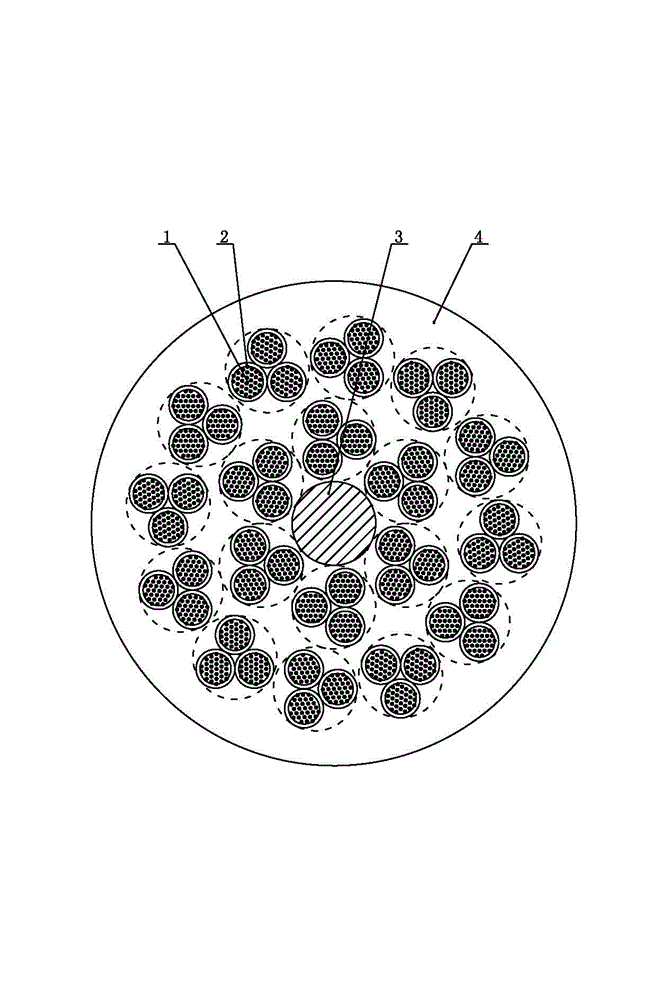

Image

Examples

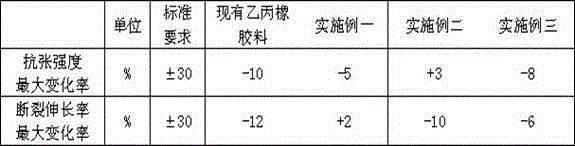

Embodiment 1

[0024] First prepare oil-resistant insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; chlorinated polyethylene rubber CM352: 15 parts; vulcanizing agent diisopropyl peroxide Benzene: 0.5 parts; vulcanizing agent triallyl isocyanurate: 0.2 parts; anti-aging agent 2-mercaptobenzimidazole: 0.3 parts; anti-aging agent 2,2,4-trimethyl-1,2 -dihydroquinoline polymer: 0.1 part; plasticizer paraffin oil: 1.0 part; plasticizer chlorinated paraffin-52: 1 part; plasticizer microcrystalline paraffin: 0.5 part; active agent activated magnesium oxide: 1.5 part Activator calcium stearate: 0.4 part; Filler superfine talcum powder: 10 parts; Reinforcing filler fumed silica: 1 part; Reinforcing filler calcined clay: 6 parts; Coloring agent: 0.2 part, The coloring agent is Huangdan pigment. (2) First, chlorinated polyethylene rubber CM352 raw rubber is kneaded on a mixer with a tempera...

Embodiment 2

[0027] First prepare oil-resistant insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; chlorinated polyethylene rubber CM352: 15 parts; vulcanizing agent diisopropyl peroxide Benzene: 0.55 parts; vulcanizing agent triallyl isocyanurate: 0.25 parts; anti-aging agent 2-mercaptobenzimidazole: 0.35 parts; anti-aging agent 2,2,4-trimethyl-1,2 -dihydroquinoline polymer: 0.2 parts; plasticizer paraffin oil: 1.5 parts; plasticizer chlorinated paraffin-52: 1.5 parts; plasticizer microcrystalline paraffin: 0.7 parts; active agent activated magnesium oxide: 2.0 parts Activator calcium stearate: 0.5 parts; filler superfine talcum powder: 13 parts; reinforcing filler fumed silica: 1.5 parts; reinforcing filler calcined clay: 7 parts; coloring agent: 0.3 parts, The coloring agent is phthalocyanine blue pigment; (2) First, chlorinated polyethylene rubber CM352 raw rubber is kneaded...

Embodiment 3

[0030] First prepare oil-resistant insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; chlorinated polyethylene rubber CM352: 15 parts; vulcanizing agent diisopropyl peroxide Benzene: 0.6 parts; vulcanizing agent triallyl isocyanurate: 0.3 parts; anti-aging agent 2-mercaptobenzimidazole: 0.5 parts; anti-aging agent 2,2,4-trimethyl-1,2 -dihydroquinoline polymer: 0.3 parts; plasticizer paraffin oil: 2.0 parts; plasticizer chlorinated paraffin-52: 2 parts; plasticizer microcrystalline paraffin: 1.0 parts; active agent activated magnesium oxide: 2.5 parts Activator calcium stearate: 0.7 parts; filler superfine talcum powder: 15 parts; reinforcing filler fumed silica: 2 parts; reinforcing filler calcined clay: 8 parts; coloring agent: 0.4 parts; (2) First, chlorinated polyethylene rubber CM352 raw rubber was kneaded on an internal mixer at a temperature of 75°C for 3.5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com