Process and device for carbon-free roasting of molybdenum concentrate in multi-hearth furnace

A multi-hearth furnace and molybdenum concentrate technology, which is applied in the field of non-ferrous metallurgy, can solve problems such as the loss of molybdenum concentrate, affecting the roasting recovery rate of molybdenum concentrate, and the wear and tear of the rake teeth of the rake arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

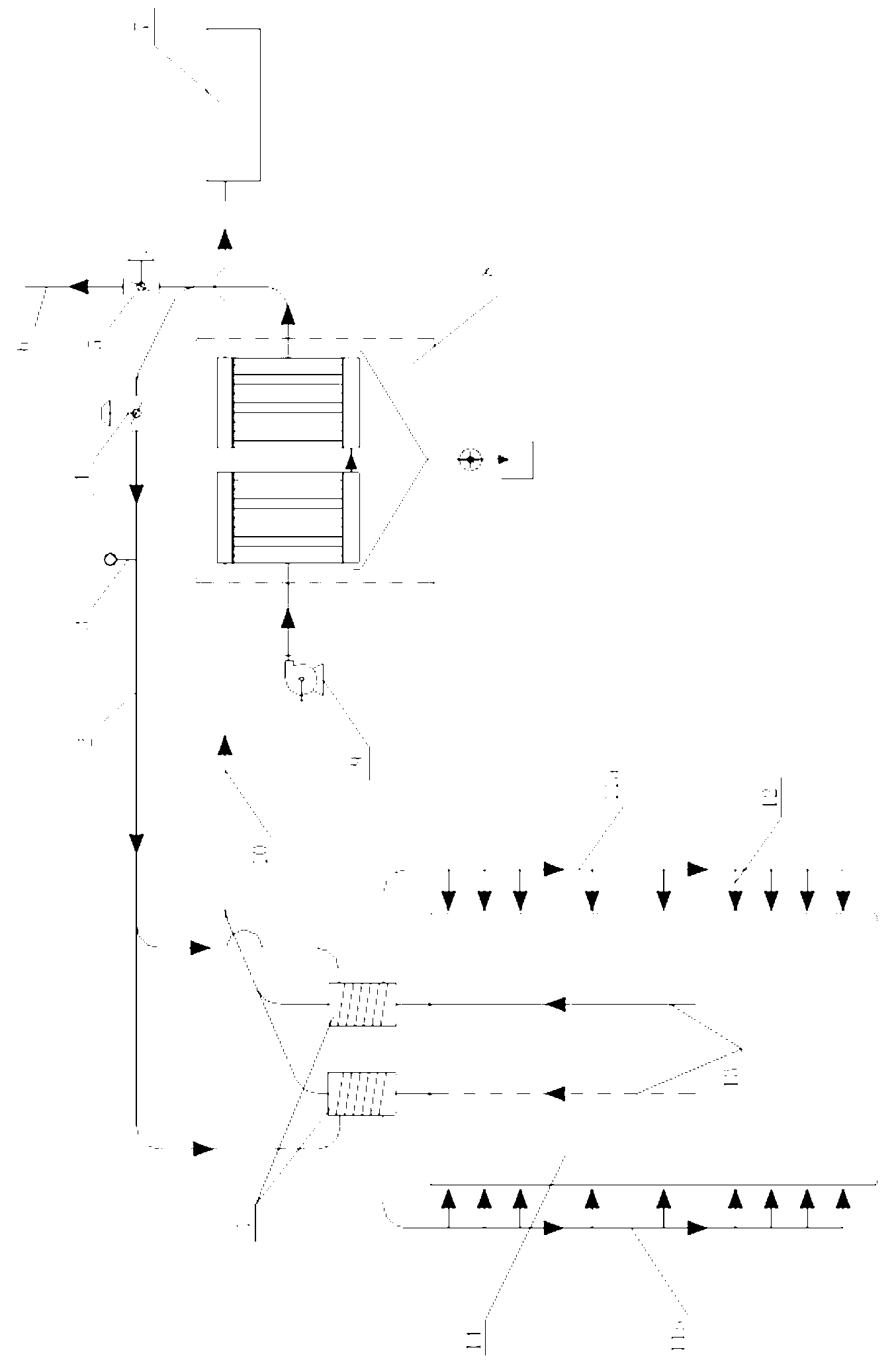

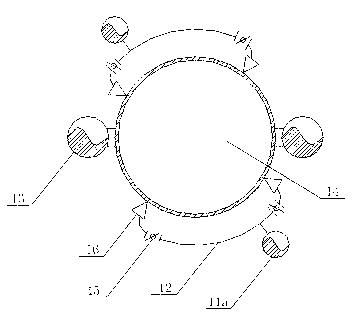

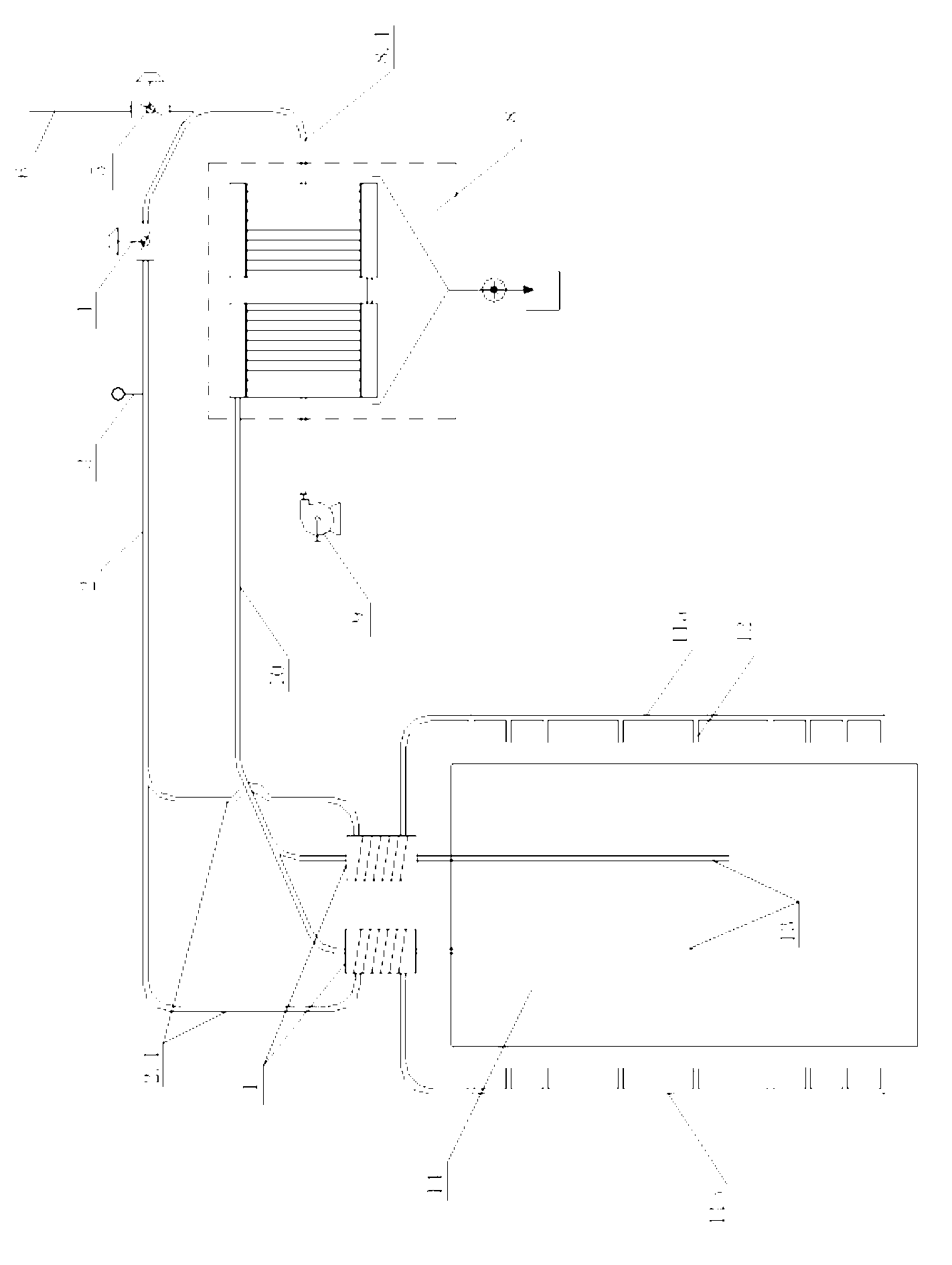

[0031] Such as figure 1 , 2 Shown, multi-hearth furnace carbonless roasting molybdenum concentrate technique of the present invention, it may further comprise the steps:

[0032] (1) The molybdenum concentrate enters the furnace body of the multi-hearth furnace 14 from the furnace top, passes through each layer of the multi-hearth furnace in turn, and the normal temperature air supplied through the air inlet on each layer of the multi-hearth furnace or the observation hole on the working door The oxygen in the furnace fully reacts to generate molybdenum trioxide, which is discharged from the bottom of the multi-hearth furnace. The high-temperature flue gas generated by each layer during the roasting process of the multi-hearth furnace is discharged from the flue gas collection pipes 13 on the front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com