Method for dry distillation extraction of plant aromatic oil

A plant aromatic oil, distillation extraction technology, applied in the direction of essential oil/spices, fat production, etc., can solve the problems of low extraction efficiency, high water content of waste residue, high energy consumption, etc., to increase distillation temperature, improve daily processing capacity, The effect of improving the oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of method for oil camphor branch, leaf aromatic oil dry distillation extraction, comprises the following steps:

[0037] a. Cinnamomum camphora branches and leaves are fed to the shredder (1) to chop the camphor leaves, and the crushed materials pass through a 10 mm sieve.

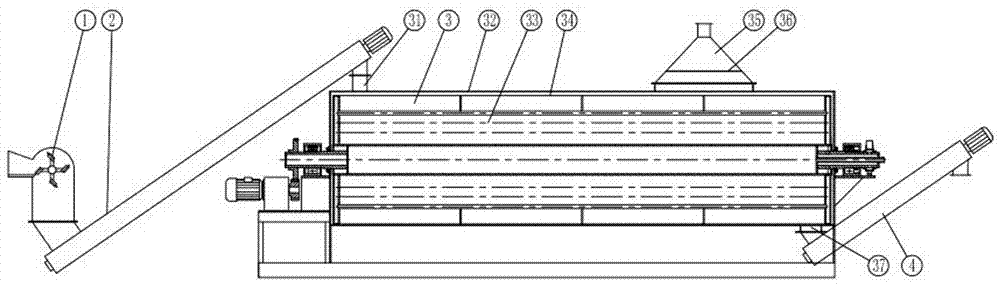

[0038] b. The chopped materials are naturally scattered into the airtight conveying device (2), and the airtight conveying device (2) conveys the chopped materials to the dry heat distillation device (3) feed port (31) and enters the dry heat distillation device ( 3) In the interior, the material is passed between the stationary shell (32) of the dry heat distillation device (3) and multiple rotating heat exchange tube bundles (33) through the shovel plate (34) installed on the heat exchange tube bundle (33) The material is scooped up and refluxed at a high position, so that the material spirally moves in the dry heat distillation device, fully and evenly contacts with the heat ...

Embodiment 2

[0041] A method for dry distillation extraction of camphor root aromatic oil, comprising the following steps:

[0042] a. The camphor root is fed to the shredder (1), the camphor root is chopped, and the crushed material is passed through a 10 mm sieve.

[0043] b. The chopped materials are naturally scattered into the airtight conveying device (2), and the airtight conveying device (2) conveys the chopped materials to the dry heat distillation device (3) feed port (31) and enters the dry heat distillation device ( 3) In the interior, the material is passed between the stationary shell (32) of the dry heat distillation device (3) and multiple rotating heat exchange tube bundles (33) through the shovel plate (34) installed on the heat exchange tube bundle (33) The material is scooped up and refluxed at a high position, so that the material spirally moves in the dry heat distillation device, and fully and evenly contacts with the heat exchange tube bundle (33) to be heated. The ...

Embodiment 3

[0046] A method for dry distillation extraction of rock osmanthus twig and leaf aromatic oil, comprising the following steps:

[0047] a. Rock osmanthus branches and leaves are fed to the shredder (1), and the rock osmanthus branches and leaves are chopped, and the crushed materials are passed through a 6 mm sieve.

[0048] b. The chopped materials are naturally scattered into the airtight conveying device (2), and the airtight conveying device (2) conveys the chopped materials to the dry heat distillation device (3) feed port (31) and enters the dry heat distillation device ( 3) In the interior, the material is passed between the stationary shell (32) of the dry heat distillation device (3) and multiple rotating heat exchange tube bundles (33) through the shovel plate (34) installed on the heat exchange tube bundle (33) The material is scooped up and refluxed at a high position, so that the material spirally moves in the dry heat distillation device, and fully and evenly cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com