Method for continuously distilling aromatic oil by subsectional temperature control

A segmented temperature control and aromatic oil technology, which is applied in the production of essential oils/fragrances, fat oil/fat, and fat production, can solve the problems of segmental temperature control, continuous distillation, and low extraction efficiency, so as to improve daily Processing capacity, uniform size, to achieve the effect of rapid distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

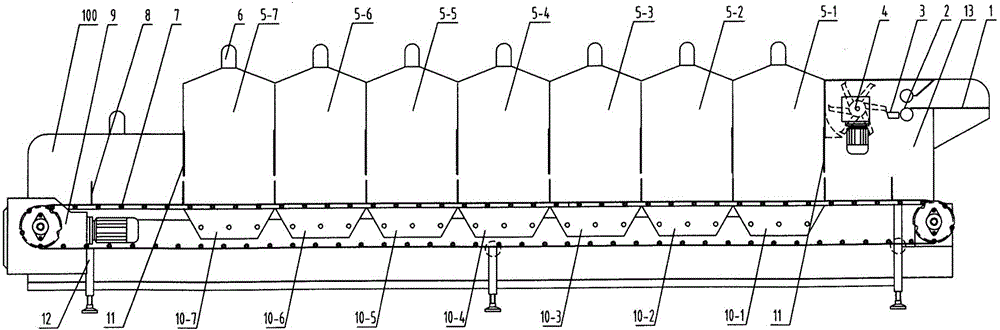

[0029] Complete machine is supported by frame 12.

[0030] The camphor leaf is manually fed to the feeding table 1, and is forced to be rolled by the biting roller 2 to be sent between the fixed cutter 3 and the rotary cutter 4, and is shredded by the rotary cutter 4.

[0031] The chopped materials naturally scatter into the closed space of the pretreatment area 13, and accumulate on the porous chain plate 7, and move to the distillation station along with the porous chain plate 7. Before entering the closed distillation station, the thickness of the material on the porous chain plate 7 is controlled to be 30 cm by the adjustable baffle 11 and the adjustable scraper 8 .

[0032] The steam zone 10 and the distillation zone 5 correspond to sections, and the temperature of each section is different and increases step by step. By automatically controlling the temperature of steam zone 10, 10-1 is 98°C, 10-2 is 108°C, 10-3 is 118°C, 10-4 is 128°C, 10-5 is 138°C, 10-6 is 148°C, 10 ...

Embodiment 2

[0034] Embodiment 2: Camphor leaves are manually fed to the feeding table 1, and are forced to be wound by the opposing roller 2 to be sent between the fixed cutter 3 and the rotary cutter 4, and are chopped by the rotary cutter 4.

[0035] The porous chain plate 7 is provided with a vertical adjustable scraper 8, and the distance between two adjacent adjustable scrapers 8 is consistent with the lateral dimension of the distillation area 5, which can not only prevent the material from slipping, but also better Realize the environmental sealing of the distillation station.

[0036] The chopped materials naturally scatter into the closed space of the pretreatment area 13, and accumulate on the porous chain plate 7, and move to the distillation station along with the porous chain plate 7. Before entering the closed distillation station, the thickness of the material on the porous chain plate 7 is controlled by the adjustable baffle plate 11 to 65cm.

[0037] The steam zone 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com