Processing apparatus for drying sludge by utilizing waste heat of draught fan and method for using the same

A technology for drying sludge and treatment equipment, which is applied in dehydration/drying/thickened sludge treatment, energy wastewater treatment, etc., and can solve problems such as large floor area, difficulty in ventilation and odor, and strong influence from sunlight and weather , to achieve the effect of high safety and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

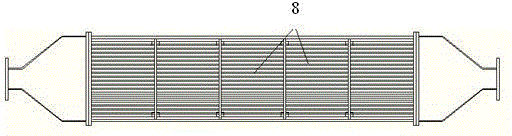

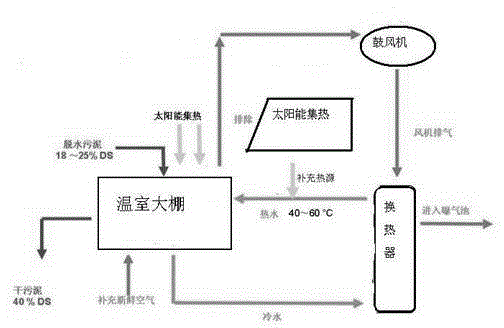

[0032] Figure 1-Figure 4 Schematically shows the structure of a preferred embodiment of the present invention, as shown in the figure, this preferred embodiment includes a solar greenhouse, a sludge pressure conveying system, a sludge drying system, an exhaust gas waste heat circulation system, and the sludge pressure conveying The system is placed in a solar greenhouse. The sludge pressure conveying system includes a screw pump (or plunger pump), a mud distributor and a belt conveyor. The solar greenhouse is connected to the exhaust gas waste heat circulation system. The waste gas waste heat circulation system includes Humidity-adjusted air intake device, aeration blower, filter, special heat exchanger, the sludge drying system is placed in the solar greenhouse, including screw pump (or plunger pump), mud distributor, sewage Mud turning and throwing machine, waste heat floor heating system, waste heat circulating air heating system, heat exchanger and temperature controller,...

Embodiment 2

[0034] In embodiment 2, other structures are all the same as embodiment 1, and the difference is: the processing device is also provided with an auxiliary energy source, the solar greenhouse is connected to the auxiliary energy source, and the auxiliary energy source is a solar thermal collector or a heat pump system, It is activated when the weather is bad or the fan fails.

Embodiment 3

[0036] In Example 3, other structures are the same as those in Example 2, except that the aeration blower is connected to a heat exchanger, and one end of the heat exchanger is connected to a water pipe to transfer heat to water for heating the sludge. Connect the filter, after the exhaust gas is treated, it will be compressed by the aeration blower and heated up, and then the heat will be exchanged through the heat exchanger, and then discharged into the aeration tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com