Driving device of gear-synchronous cog belt numerical control plate shearing machine

A synchronous toothed belt and driving device technology, applied in the direction of shearing devices, shearing machine equipment, metal processing equipment, etc., can solve the problems of low transmission efficiency, oil leakage environment, difficult maintenance, etc., and achieve the improvement of shearing width and Accuracy, improved work ability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

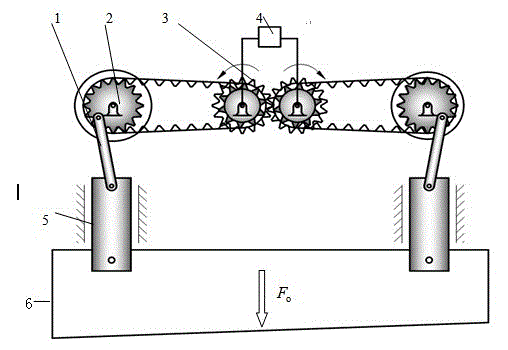

[0021] Embodiment one: see figure 1 As shown, a gear-synchronous toothed belt CNC shearing machine driving device includes a connecting rod 1, a synchronous toothed wheel 2, a servo motor 3, a numerical control system 4, a slider 5 and a tool holder 6.

[0022] The tooth profile of the synchronous toothed belt and the teeth of the synchronous toothed wheel 2 mesh successively to transmit motion and power. The gear engagement ensures that the rotating speeds of the left and right synchronous toothed wheels 2 are the same, and the actions of the left and right sliding blocks connected thereto also guarantee synchronization.

[0023] The synchronous toothed wheel 2 drives the slider 5 through the connecting rod 1 to drive the knife rest 6 to reciprocate up and down, so as to realize the function of cutting the plate.

[0024] The working principle of the gear-synchronous toothed belt CNC shearing machine driving device is as follows:

[0025] When the numerical control system 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com