High-current battery system and method for controlling a high-current battery system

A battery system, high current technology, applied in battery/fuel cell control devices, battery circuit devices, different battery charging and other directions, can solve the problems of high current switching expensive and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

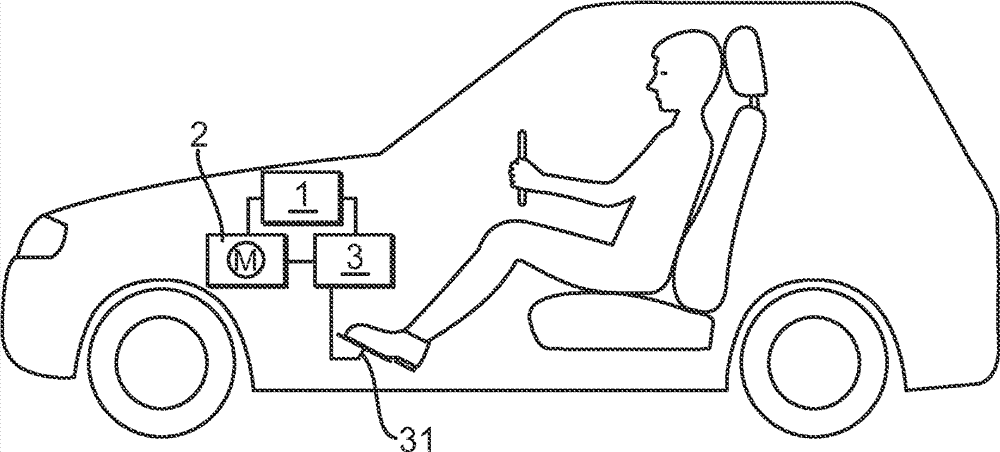

[0047] figure 1 An electric vehicle is shown having a high current battery system 1 according to the invention, an electric motor 2 and an electric motor control unit 3 controlling the electric motor 2 . Transmitter 31 for electric motor control unit 3 is designed as an electronic accelerator pedal. However, the transmitter 31 may also be a manual controller or the like. When the electric vehicle is running, more or less energy is drained from the high current battery system 1 and delivered to the electric motor 2 depending on the position of the electric "gas pedal" 31 . The current flow is correspondingly sized. When it is recognized that the bypass battery module 6 has a fault state, the load current flowing between the high-current battery system 1 and the electric motor 2 is preferably controlled via the electric motor control unit 3 so that the operating current line of the high-current battery system 1 The current flowing between the plurality of battery modules 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com